Catalyst for preparing pyromellitic dianhydride through durene gas phase oxidation

A technology of pyromethylene and gas-phase oxidation, which is applied in physical/chemical process catalysts, organic chemistry, chemical instruments and methods, etc., can solve the problems of low yield of mono-anhydride and high yield of mono-anhydride, and achieve improved activity and stability. , the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

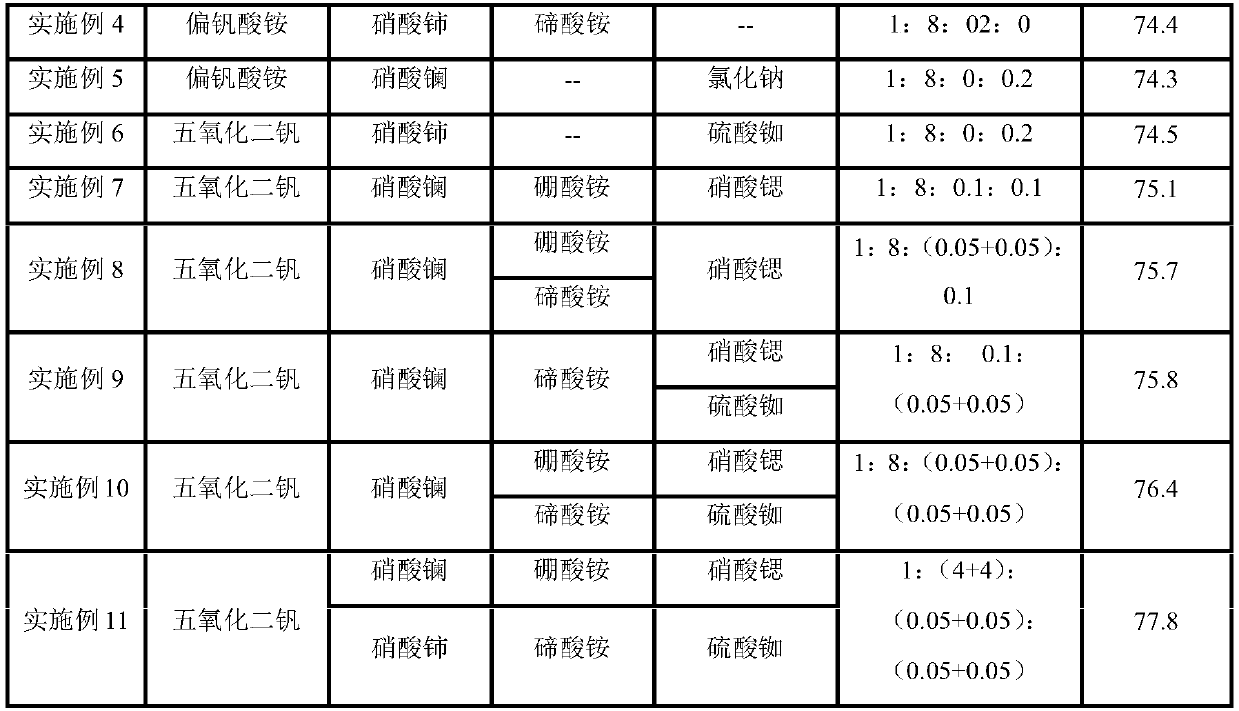

Examples

Embodiment 1

[0025] Weigh 95g of oxalic acid and 380ml of distilled water in a flask, stir and raise the temperature to 85°C, after the oxalic acid is completely dissolved, make an oxalic acid solution. Add 1 part of vanadium pentoxide to the prepared oxalic acid solution and continue stirring to obtain ammonium vanadyl oxalate solution. Add 8 parts of lanthanum nitrate and 0.2 parts of ammonium borate into the solution, and continue stirring evenly to obtain a catalyst precursor. After the catalyst precursor is filtered and dried, it is loaded into a spraying machine and evenly sprayed on the inert carrier silicon carbide. The inert carrier sprayed with the catalyst precursor was baked in a muffle furnace at 530°C, and the catalyst was obtained after natural cooling. Catalyst at a reaction temperature of 525°C and a space velocity of 5150h -1 Next, it was evaluated in a fixed-bed reactor, and the average anhydride yield was measured to be 74.0%. The evaluation results are shown in Table...

Embodiment 2

[0027] Weigh 95g of oxalic acid and 380ml of distilled water in a flask, stir and raise the temperature to 85°C, after the oxalic acid is completely dissolved, make an oxalic acid solution. Add 1 part of vanadium pentoxide to the prepared oxalic acid solution and continue stirring to obtain ammonium vanadyl oxalate solution. Add 8 parts of lanthanum nitrate and 0.2 parts of strontium nitrate into the solution, and continue stirring evenly to obtain a catalyst precursor. After the catalyst precursor is filtered and dried, it is loaded into a spraying machine and evenly sprayed on the inert carrier silicon carbide. The inert carrier sprayed with the catalyst precursor was baked in a muffle furnace at 530°C, and the catalyst was obtained after natural cooling. Catalyst at a reaction temperature of 525°C and a space velocity of 5150h -1 Next, it was evaluated in a fixed-bed reactor, and the average anhydride yield was measured to be 73.9%. The evaluation results are shown in Tab...

Embodiment 3

[0032] Weigh 95g of oxalic acid and 380ml of distilled water in a flask, stir and raise the temperature to 85°C, after the oxalic acid is completely dissolved, make an oxalic acid solution. Add 1 part of vanadium pentoxide to the prepared oxalic acid solution and continue stirring to obtain ammonium vanadyl oxalate solution. Add 8 parts of cerium nitrate and 0.2 parts of ammonium tellurate into the solution, and continue stirring to obtain a catalyst precursor. After the catalyst precursor is filtered and dried, it is loaded into a spraying machine and evenly sprayed on the inert carrier silicon carbide. The inert carrier sprayed with the catalyst precursor was baked in a muffle furnace at 530°C, and the catalyst was obtained after natural cooling. Catalyst at a reaction temperature of 525°C and a space velocity of 5150h -1Next, it was evaluated in a fixed-bed reactor, and the average anhydride yield was measured to be 74.2%. The evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com