A horizontal liquefied gas sweetening tank

A technology for liquefied gas and desulfurization, which is applied in gas fuel, gas treatment, chemical instruments and methods, etc., can solve the problems of increased mercaptan content, increased liquefied gas processing capacity, unqualified liquefied gas sulfur content, etc. The effect of convenience, compact structure and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

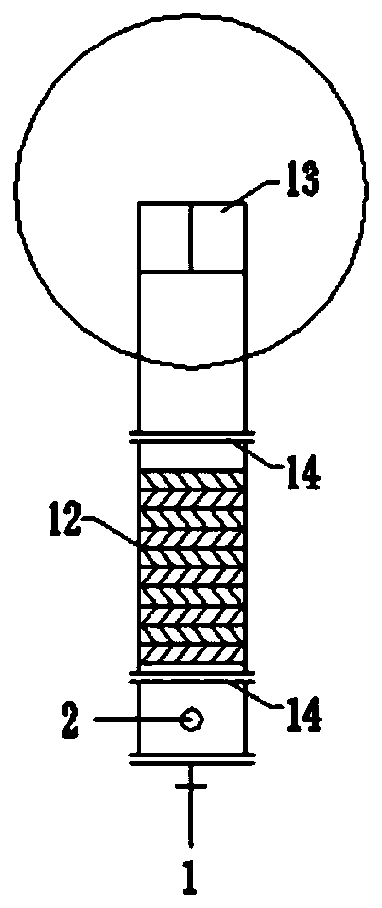

[0033] According to one embodiment, the cross-sectional area of the extraction element 12 and the buffer tube 13 is 0.005-0.126m 2 .

[0034] In addition, the distance between the buffer pipe 13 and the tangent line on one side of the sweetening tank should be as short as possible according to the requirements of equipment manufacturing, which can further reduce the footprint of the horizontal liquefied gas sweetening tank.

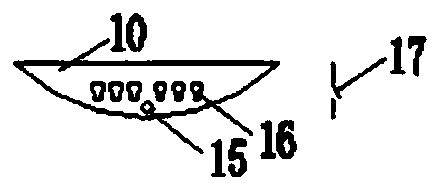

[0035] As a preferred solution, such as image 3 As shown, the overflow plate 10 is a bow-shaped plate. The overflow plate 10 is provided with a guide hole 15 and a trapezoidal hole 16. The trapezoidal hole 16 is wide at the top and narrow at the bottom and has a hole cover 17. The hole cover 17 is obliquely downward and overflowing. The flow plate 10 forms an included angle of 15-30 degrees. The guide hole 15 is preferably one, and the trapezoidal hole 16 is preferably multiple.

[0036] As a preferred solution, the height of the overflow plate 10 i...

Embodiment

[0047] The discharge liquefied gas flow rate of a liquefied gas extraction tower in a factory is 19995 kg / h, and the mass content of mercaptan sulfur is 45ppm, that is, the amount calculated in terms of mercaptan sulfur is 0.9 kg / h, and the mass content of mercaptan sulfur is not greater than 10ppm product index requirements.

[0048] According to this embodiment figure 1 The horizontal liquefied gas sweetening tank shown (combined with Figure 2 to Figure 4 ) to remove the mercaptans in the discharged liquefied gas. Among them, the specification of the tank body is Φ2800×6000, and the cross-sectional area of the extraction element 12 and the buffer tube 13 is 0.018m 2 , The packing height is 2.2m. The horizontal liquefied gas sweetening tank is connected in series after the liquefied gas extraction tower.

[0049] The mercaptan-containing liquefied gas and lye enter the liquefied gas sweetening tank from liquefied gas inlet 1 and lye inlet 2 respectively (the flow ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com