Preparation method of pure lead lead-carbon battery and pure lead lead-carbon battery

A lead-carbon battery and lead powder technology, which is applied to battery electrodes, lead-acid batteries, circuits, etc., can solve problems such as shortened cycle life, hinder electrolyte entry, and deteriorate battery cycle performance, so as to improve cycle performance and charge acceptance. The effect of ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

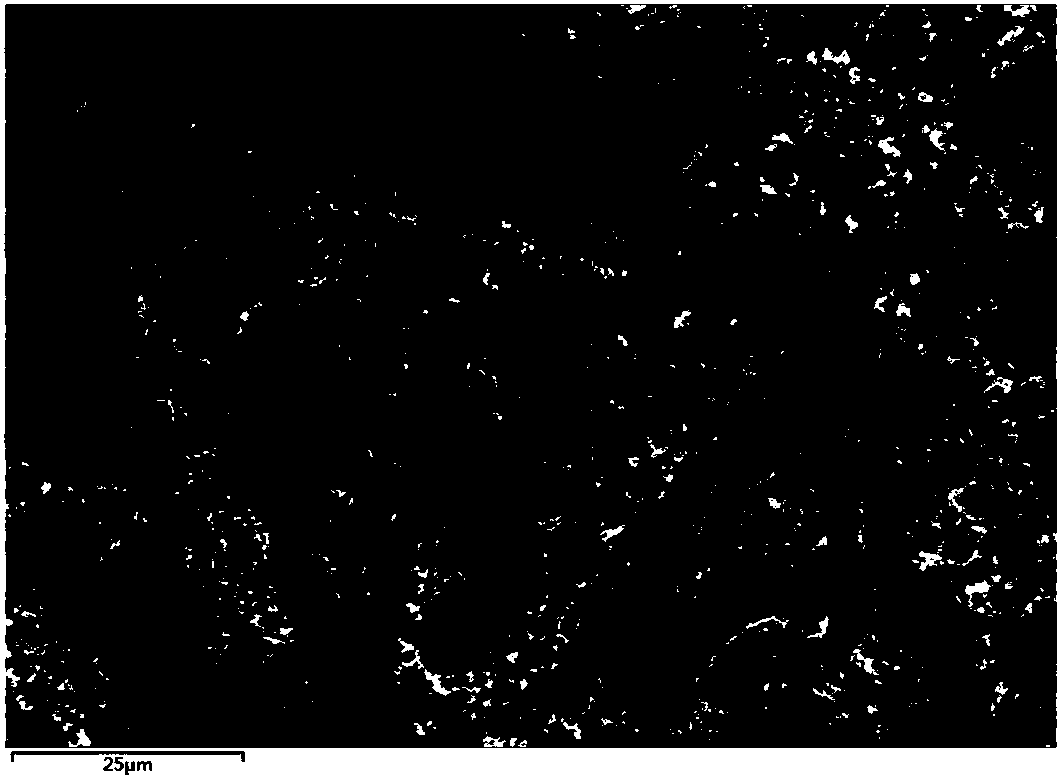

Image

Examples

Embodiment 1

[0032] Choose natural flake graphite as conductive graphite, with a specific surface area of 1300m 2 / g, mesoporous activated carbon is high specific surface area carbon. Follow the steps below to configure the negative lead paste (number A):

[0033] (1) Weigh 100 parts of lead powder, 1.0 part of barium sulfate, 0.2 part of lignin, 0.06 part of short fiber and 0.4 part of humic acid into the paste mixer, dry mix and stir for 8 minutes.

[0034] (2) Add 0.5 parts of conductive graphite and 0.5 parts of high specific surface area activated carbon to 10 parts of alcohol and water mixed solution (the volume ratio of alcohol to water is 1:4), and stir at 500rpm for 5 minutes to form uniformly dispersed carbon Predispersion.

[0035] (3) In the process of keeping the mixed ingredients composed of lead powder and other auxiliary materials under stirring, slowly add the dispersed carbon pre-dispersion liquid at a speed not exceeding 5mL / min, stir while adding, and then stir for ...

Embodiment 2

[0039] Choose expanded graphite as conductive graphite with a specific surface area of 1000m 2 / g, macropore-based activated carbon is high specific surface area carbon. Follow the steps below to configure the negative lead paste (number B):

[0040] (1) Weigh 100 parts of lead powder, 1.5 parts of barium sulfate, 0.4 parts of lignin, 0.05 parts of short fibers and 0.4 parts of humic acid and add them to the paste mixer, dry mix and stir for 8 minutes.

[0041] (2) Add 0.5 parts of conductive agent graphite and 1.0 part of high specific surface area activated carbon to a mixed solution of 10 parts of alcohol and water (the volume ratio of alcohol to water is 1:2), and stir at 400rpm for 5 minutes to form a uniformly dispersed Carbon predispersion.

[0042] (3) In the process of keeping the mixed ingredients composed of lead powder and other auxiliary materials under stirring, slowly add the dispersed carbon pre-dispersion liquid at a speed not exceeding 5mL / min, stir while...

Embodiment 3

[0045] Embodiment 3 (comparative example 1)

[0046] The lead paste produced by the original production process of the workshop is used as a blank control sample (numbered as C), and the specific production steps are as follows:

[0047] (1) Weigh 100 parts of lead powder, 1.5 parts of barium sulfate, 0.4 part of lignin, 0.05 part of short fiber, 0.4 part of humic acid, 0.1 part of ordinary graphite and 0.3 part of acetylene black and add them to the paste mixing machine. Blend for 8 minutes.

[0048] (2) Add 8 parts of pure water to the above mixed ingredients, and stir for 5 minutes at 1000rpm;

[0049] (3) Add 10 parts to the above paste mixing machine with a density of 1.260g / cm 3 sulfuric acid, stirred for 8 minutes, and then added to adjust the water to make a lead paste. Control the apparent density of the lead paste to 4.35±0.05g / cm 3 , The temperature of the lead paste is less than 45°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com