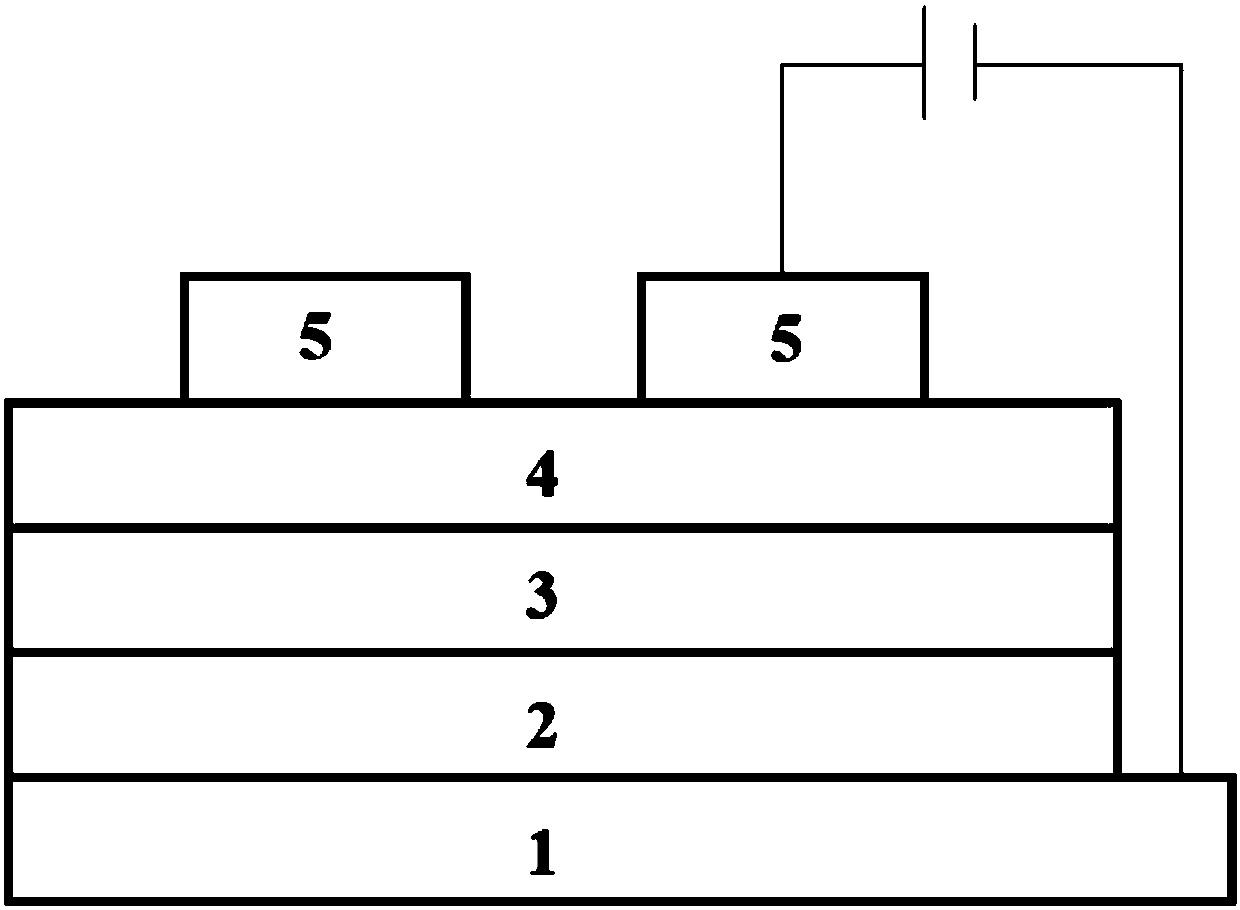

All-inorganic light-emitting device based on perovskite thin film and preparation method thereof

A light-emitting device, perovskite technology, applied in the direction of semiconductor devices, nanotechnology for materials and surface science, electrical components, etc., to achieve the effect of high luminous purity, stable performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

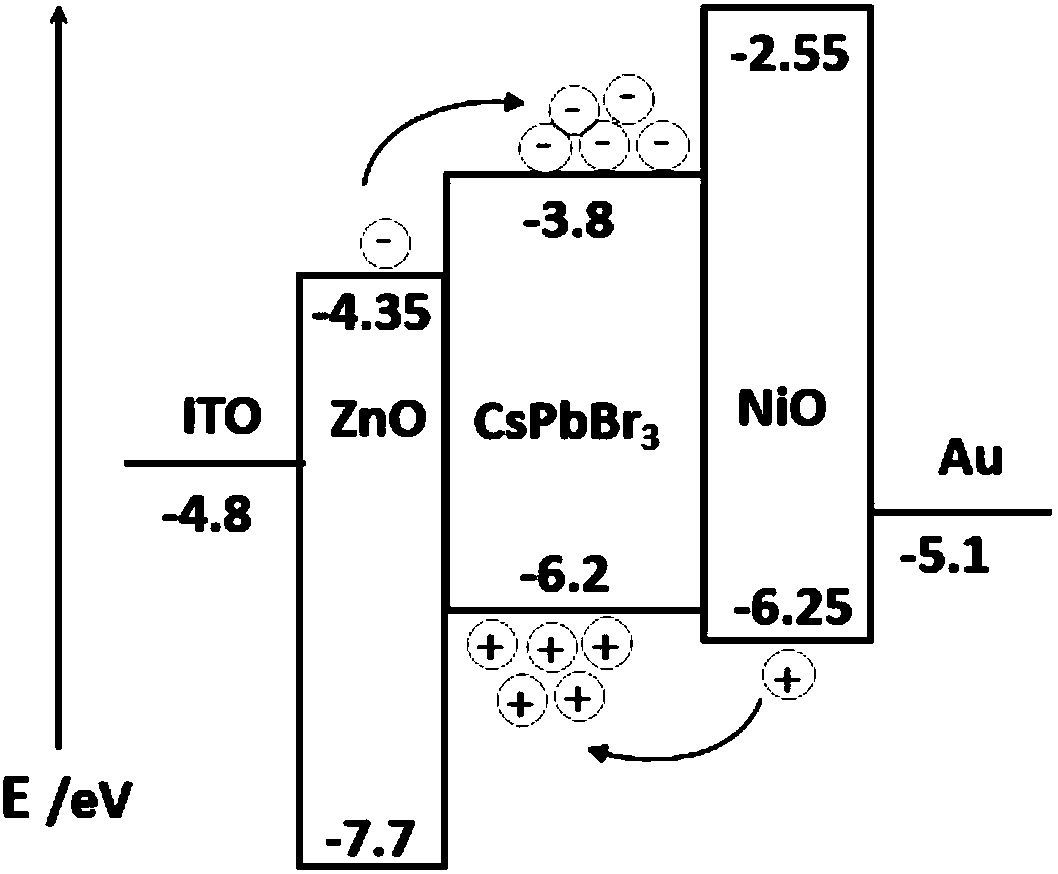

Method used

Image

Examples

Embodiment 1

[0026] (1) Use toluene, acetone, ethanol, and deionized water in sequence to ultrasonically clean the ITO glass substrate for 5 minutes, and then dry the substrate with a nitrogen gun for later use;

[0027] (2) Deposit the ZnO electron transport layer 2 on the ITO conductive film of the cleaned ITO glass substrate by magnetron sputtering. The target used for sputtering is a ZnO target with a diameter of 46 mm and a copper back target of 50 mm, Ar and O 2 The gas flow rate is 40sccm, the reaction chamber pressure is set to 20mTorr, the sputtering power of the RF source is set to 70W, the target speed is 25 rpm, and the final deposition thickness is 50nm;

[0028] (3) Depositing PbBr on the ZnO electron transport layer by thermal evaporation 2 layer, and then soak the obtained device into a saturated ethanol solution of CsBr for 15 minutes, and anneal at 85°C for 25 minutes after the reaction is complete, and prepare the inorganic perovskite CsPbBr 3 Thin film light emitting ...

Embodiment 2

[0033] (1) Use toluene, acetone, ethanol, and deionized water to clean the ITO glass substrate ultrasonically for 5 minutes, and then dry the substrate with a nitrogen gun for later use.

[0034] (2) Deposit the ZnO electron transport layer 2 on the ITO conductive film of the cleaned ITO glass substrate by magnetron sputtering. The target used for sputtering is a ZnO target with a diameter of 46 mm and a copper back target of 50 mm, Ar and O 2 The gas flow rate is 40sccm, the reaction chamber pressure is set to 20mTorr, the sputtering power of the RF source is set to 70W, the target speed is 25 rpm, and the final deposition thickness is 50nm;

[0035] (3) Depositing PbI on the ZnO electron transport layer by thermal evaporation 2layer, and then soak the obtained device in a saturated ethanol solution of CsI for 15 minutes, and anneal at 80-90°C for 25 minutes after the reaction is complete, to prepare the inorganic perovskite CsPbI 3 Thin film light emitting layer. Thermall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com