Architectural reflective heat insulation coating and preparation method thereof

A technology for reflective thermal insulation coatings and buildings, applied in the field of coatings, can solve the problems of single color, large limitations and restrictions, and achieve the effects of reducing heat conduction, reducing heat convection and high visible light reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

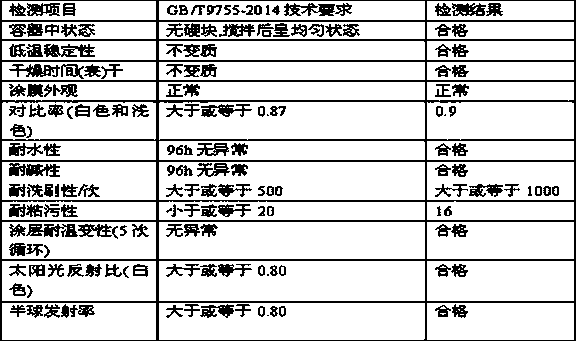

Image

Examples

Embodiment 1

[0034] A kind of architectural reflective heat-insulating paint, characterized in that: it is made of the following raw materials in parts by weight:

[0035] Emulsion: 300 parts

[0036] Reflective functional filler: 50 parts

[0037] Other pigments and fillers: 150 parts

[0038] Hydroxyethylcellulose: 1 part

[0039] Defoamer: 2 parts

[0040] PH adjuster: 1 part

[0041] Wetting agent: 2 parts

[0042] Dispersant: 3 parts

[0043] Thickener: 3 parts

[0044] Leveling agent: 6 parts

[0045] Preservatives: 1 part

[0046] Antifreeze: 8 parts

[0047] Coalescing aid: 1 part

[0048] Deionized water: 300 parts.

[0049] The emulsion is a mixed emulsion of water-based pure acrylic emulsion: water-based styrene-acrylic emulsion, which is blended according to the mass ratio of water-based pure acrylic emulsion: water-based styrene-acrylic emulsion of 6:4.

[0050] The reflective functional filler is hollow glass microspheres, solid ceramic microspheres, reflective po...

Embodiment 2

[0058] A kind of architectural reflective heat-insulating paint, characterized in that: it is made of the following raw materials in parts by weight:

[0059] Emulsion: 500 parts

[0060] Reflective functional filler: 90 parts

[0061] Other pigments and fillers: 200 parts

[0062] Hydroxyethylcellulose: 2 parts

[0063] Defoamer: 5 parts

[0064] PH adjuster: 3 parts

[0065] Wetting agent: 4 parts

[0066] Dispersant: 8 parts

[0067] Thickener: 6 parts

[0068] Leveling agent: 12 parts

[0069] Preservatives: 3 servings

[0070] Antifreeze: 15 parts

[0071] Coalescing aids: 3 parts

[0072] Deionized water: 500 parts.

[0073] The emulsion is a mixed emulsion of water-based pure acrylic emulsion and water-based styrene-acrylic emulsion, which is blended according to the mass ratio of pure acrylic emulsion: styrene-acrylic emulsion 6:4.

[0074] The reflective functional filler is hollow glass microspheres, solid ceramic microspheres, reflective powder, and UV-res...

Embodiment 3

[0082] A kind of architectural reflective heat-insulating paint, characterized in that: it is made of the following raw materials in parts by weight:

[0083] Emulsion: 400 parts

[0084] Reflective functional filler: 60 parts

[0085] Other pigments and fillers: 180 parts

[0086] Hydroxyethylcellulose: 1.5 parts

[0087] Defoamer: 3.5 parts

[0088] PH regulator: 2.2 parts

[0089] Wetting agent: 3 parts

[0090] Dispersant: 5.6 parts

[0091] Thickener: 4.3 parts

[0092] Leveling agent: 8 parts

[0093] Preservatives: 1.5 parts

[0094] Antifreeze: 9 parts

[0095] Coalescing aid: 1.5 parts

[0096] Deionized water: 380 parts.

[0097] The emulsion is a mixed emulsion of water-based pure acrylic emulsion and water-based styrene-acrylic emulsion, which is blended according to the mass ratio of pure acrylic emulsion: styrene-acrylic emulsion 6:4.

[0098] The reflective functional filler is hollow glass microspheres, solid ceramic microspheres, reflective powder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com