A kind of preparation method of one-component high-temperature self-crosslinking waterborne polyurethane

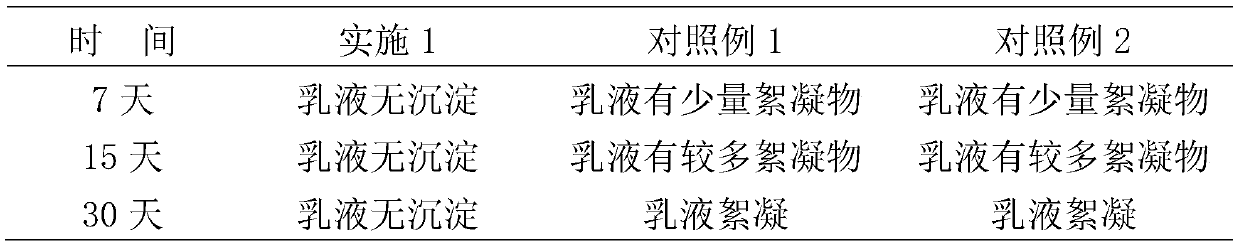

A water-based polyurethane, self-crosslinking technology, applied in coatings and other directions, can solve the problems of unsatisfactory crosslinking effect, poor storage stability of emulsion, short service life of emulsion at high temperature, etc., to achieve excellent water resistance, excellent physical and mechanical properties, long The effect of high temperature service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

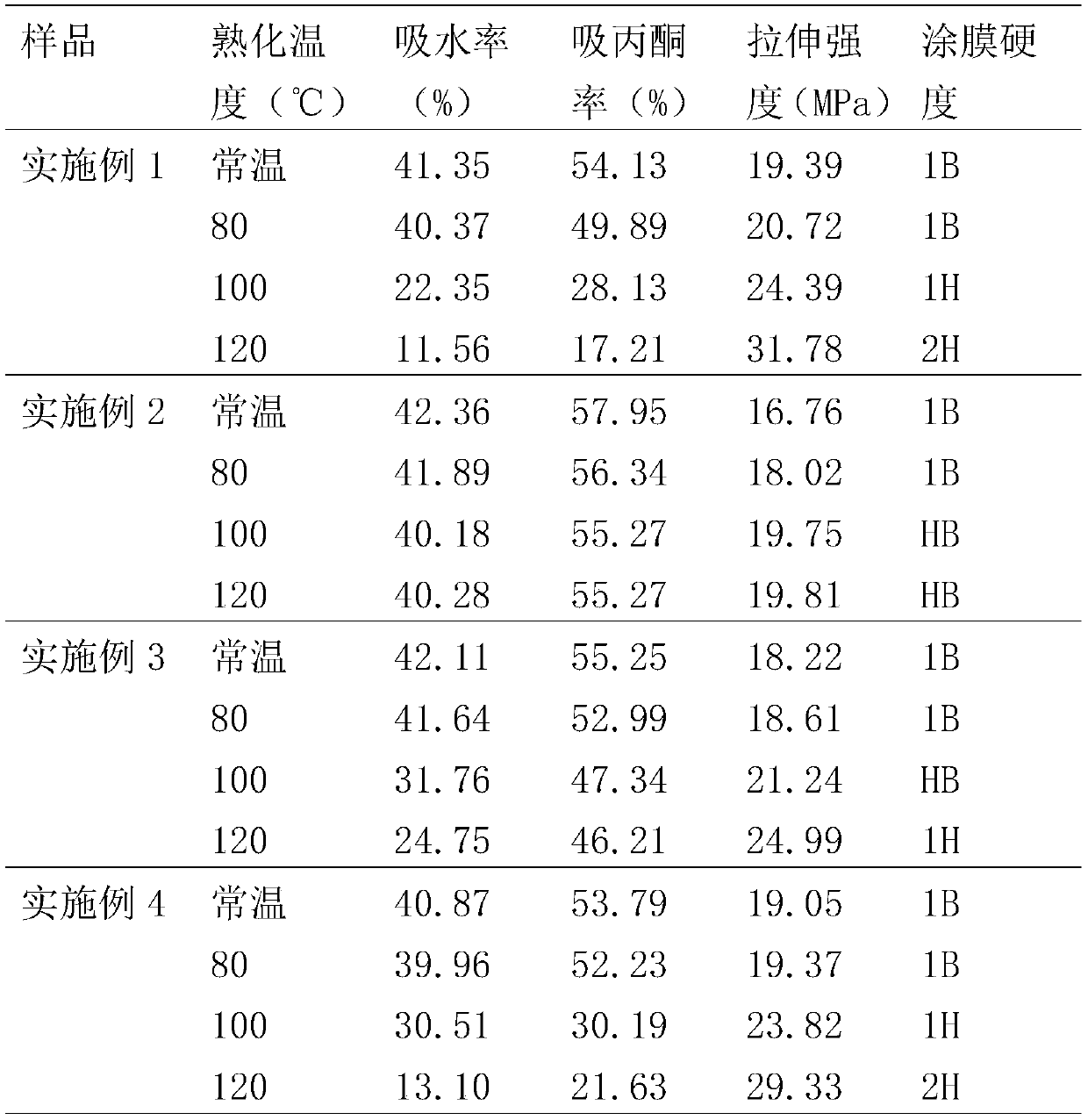

Examples

Embodiment 1

[0031] (1) Synthesis of waterborne polyurethane

[0032] Add 30 parts of Pol-2356 (hydroxyl value 54~56mg KOH / g, produced by Qingdao Yutian Chemical Industry), 1 part of trimethylolpropane (Sweden Pastor Company), and 4 parts of dimethylolpropane into the reactor. (DMPA) Hydrophilic Agent (Sweden Pastor Company), heated to 70℃ with sufficient stirring, added 25 parts of isophorone diisocyanate, heated to 75~85℃, reacted for 3~5 hours, added 8 parts The capping agent hydroxyethyl acrylate is reacted for 2 to 3 hours, then the temperature is lowered to 50°C, 2 parts of the salt forming agent are added, and the salt is formed for 10 minutes, 120 parts of deionized water are added, and the material is discharged after stirring for 60 minutes to obtain the required water Polyurethane.

[0033] (2) Synthesis of oxazoline-polyacrylate / waterborne polyurethane copolymer emulsion

[0034] A. Preparation of pre-emulsion

[0035] Take 100 parts of the synthesized waterborne polyurethane, add 70...

Embodiment 2

[0039] Repeat the steps of Example 1 except that 2-vinyl-2-oxazoline is not added in the copolymerization, and the others are the same as in Example 1.

Embodiment 3

[0041] Repeat the steps of Example 1 except that 2 parts of 2-vinyl-2-oxazoline are added to the copolymerization, and the others are in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com