Flue-gas treatment device

A technology of flue gas treatment and flue gas, which is applied in the direction of gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of poor flue gas denitrification effect, high nitrogen oxide content, and failure to meet national standards, etc., and achieve desulfurization and denitrification effects Good, good effect, the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

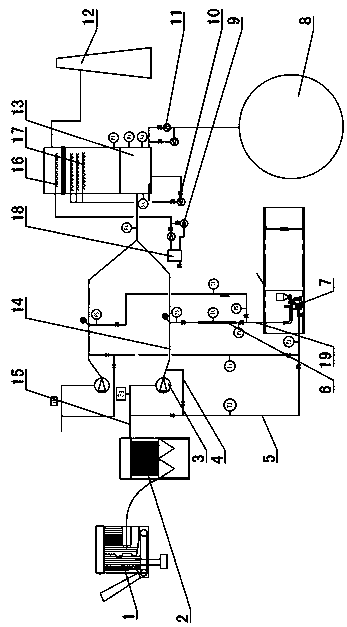

[0042] Such as figure 1 As shown: the flue gas treatment device also includes a dust collector 2, the intake end of the dust collector 2 is connected with the smoke outlet of the boiler 1, and the flue gas of the boiler 1 first enters the dust collector 2 to remove dust and then enters the main flue 14 , so as to prevent the smoke from affecting the mixing of the sodium bicarbonate powder and the flue gas, and also prevent the smoke from affecting the reaction of the sodium bicarbonate powder and the sulfur oxides and nitrogen oxides in the flue gas. The dust collector 2 can be a bag dust collector, an electric dust collector or a tubular dust collector, etc.

[0043] The gas outlet end of the dust collector 2 is communicated with the intake end of the main flue 14 through the flue gas input channel 15, and the output end of the main flue 14 is connected with the dust removal module. In the present embodiment, the dust removal module is a washing tower 13, and the main flue T...

Embodiment 2

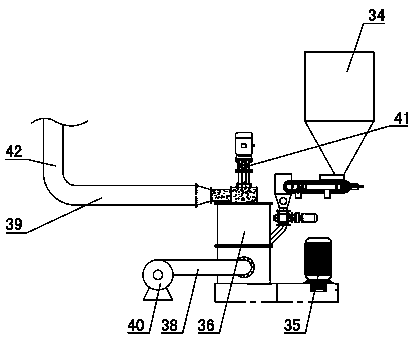

[0084] Such as Figure 6~7 Shown: the difference between embodiment 2 and embodiment 1 is: the grinding device is arranged between the powder delivery pipe 39 and the grinding device smoke outlet pipe 42, and the transportation of sodium bicarbonate powder is realized by means of negative pressure transportation. The smoke inlet pipe 38 of the grinding device is arranged at intervals on the lower side of the powder conveying pipe 39, and a balance pipe 37 is arranged between the smoke inlet pipe 38 of the grinding device and the powder conveying pipe 39, and the balance pipe 37 is vertically arranged, and the balance pipe 37 The upper end communicates with the middle part of the powder conveying pipe 39, and the lower end of the balance pipe 37 communicates with the smoke inlet pipe 38 of the grinding device, so that the pressure of the smoke inlet pipe 38 of the grinding device and the powder conveying pipe 39 can be balanced to ensure that the flue gas and sodium bicarbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com