Preparation method of nano drug-loading system of leaf surface affiliated pesticide

A nano-drug and pesticide technology, which is applied in the fields of botanical equipment and methods, insecticides, animal repellents, etc., can solve the problems of low yield, less than 0.1% of the drug received, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1: Production of foliar-friendly efficient-cyhalothrin nano-loading system

[0074] The implementation steps of this embodiment are as follows:

[0075] A. Synthesis of polylactic acid carrier material

[0076] According to dichloromethane and HO-PLA-COOCH 2 CH 3 The weight ratio of 10:1, the HO-PLA-COOCH 2 CH 3 Dissolve in dichloromethane solvent to obtain solution 1; then according to the weight ratio of dichloromethane and triethylamine 1:0.003, dissolve triethylamine in dichloromethane to obtain solution 2, and mix solution 2 into the above solution 1; Under the condition of ice bath, slowly add acetyl chloride with a weight ratio of 0.001:106: dichloromethane solution to the above mixture; after stirring at room temperature for 4 h, add 1.0% NaHCO 3 extracted, and washed twice with distilled water; the collected organic phase was washed with anhydrous Na 2 SO 4 Dry overnight; polylactic acid carrier material is obtained after rotary evaporation of th...

Embodiment 2

[0085]Example 2: Production of Leaf-Affinity Chlorantraniliprole Nano-Drug Carrier System

[0086] The implementation steps of this embodiment are as follows:

[0087] A. Synthesis of polylactic acid carrier material

[0088] According to dichloromethane and HO-PLA-COOCH 2 CH 3 The weight ratio of 10:1, the HO-PLA-COOCH 2 CH 3 Dissolve in dichloromethane solvent to obtain solution 1; then according to the weight ratio of dichloromethane and triethylamine 1:0.003, dissolve triethylamine in dichloromethane to obtain solution 2, and mix solution 2 into the above solution 1; Under the condition of ice bath, slowly add acetyl chloride with a weight ratio of 0.001:106: dichloromethane solution to the above mixture; after stirring at room temperature for 4 h, add 1.0% NaHCO 3 extracted, and washed twice with distilled water; the collected organic phase was washed with anhydrous Na 2 SO 4 Dry overnight; polylactic acid carrier material is obtained after rotary evaporation of th...

Embodiment 3

[0097] Example 3: Production of Leaf-Affinity Lambda-Cyhalothrin Nano-Drug Carrier System

[0098] The implementation steps of this embodiment are as follows:

[0099] A. Synthesis of polylactic acid carrier material

[0100] According to dichloromethane and HO-PLA-COOCH 2 CH 3 The weight ratio of 10:1, the HO-PLA-COOCH 2 CH 3 Dissolve in dichloromethane solvent to obtain solution 1; then according to the weight ratio of dichloromethane and triethylamine 1:0.003, dissolve triethylamine in dichloromethane to obtain solution 2, and mix solution 2 into the above solution 1; Under the condition of ice bath, slowly add acetyl chloride with a weight ratio of 0.001:106: dichloromethane solution to the above mixture; after stirring at room temperature for 4 h, add 1.0% NaHCO 3 extracted, and washed twice with distilled water; the collected organic phase was washed with anhydrous Na 2 SO 4 Dry overnight; polylactic acid carrier material is obtained after rotary evaporation of th...

PUM

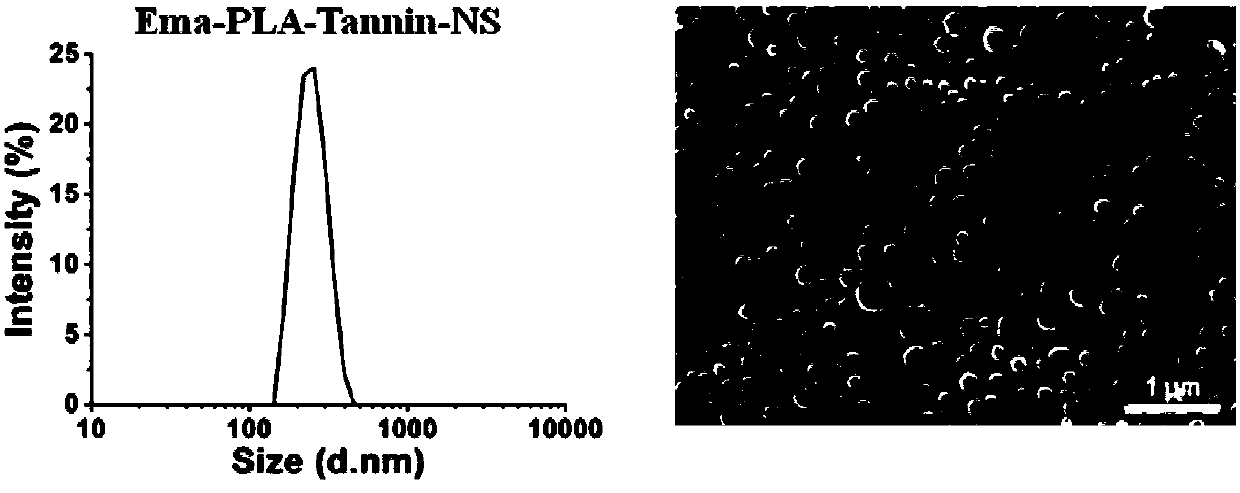

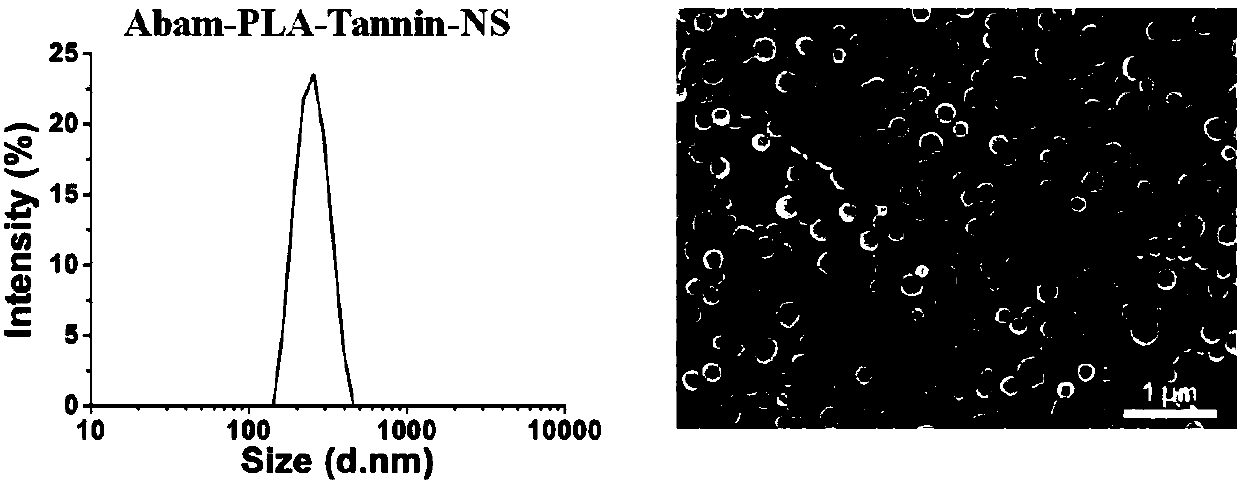

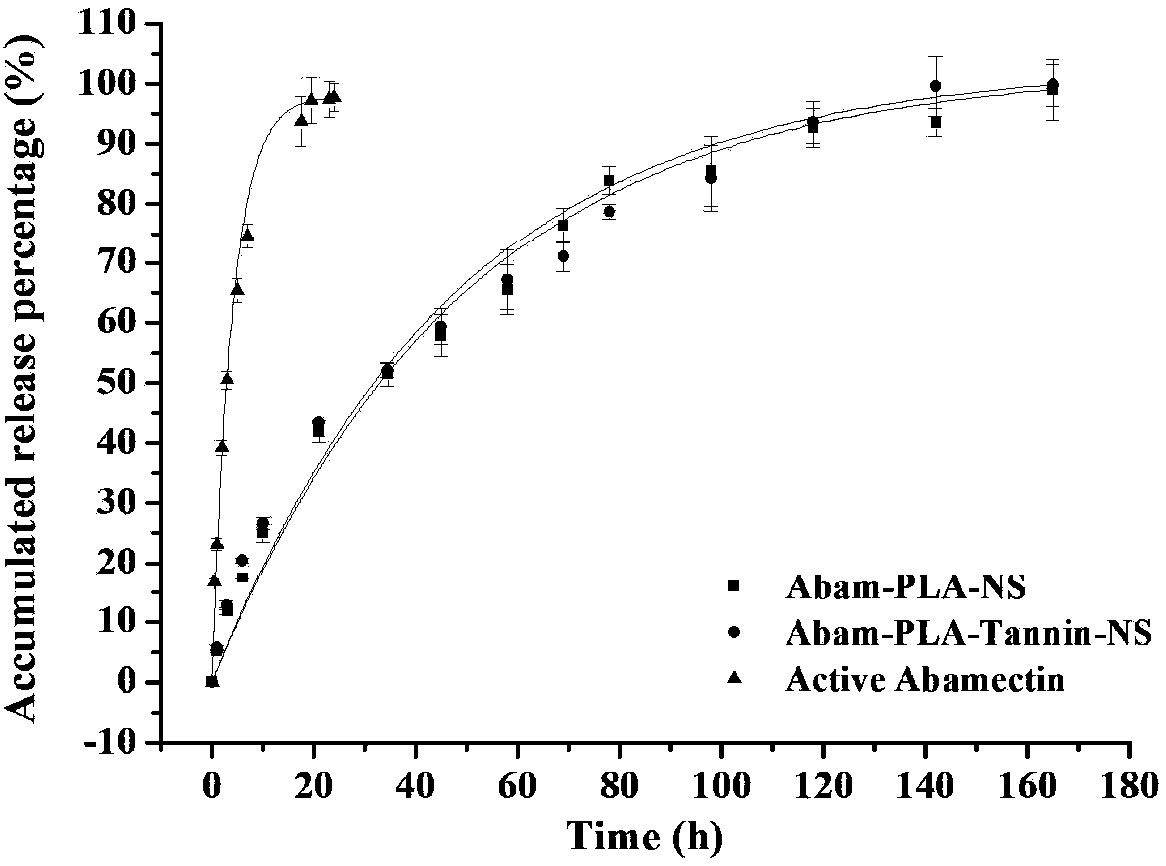

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com