Method for preparing double-layer pitch carbon-coated lithium iron phosphate cathode material

A technology of carbon-coated lithium iron phosphate and positive electrode materials, which is applied to battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of limited improvement in electrochemical performance, and achieve optimal potential energy distribution and conductivity. High, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

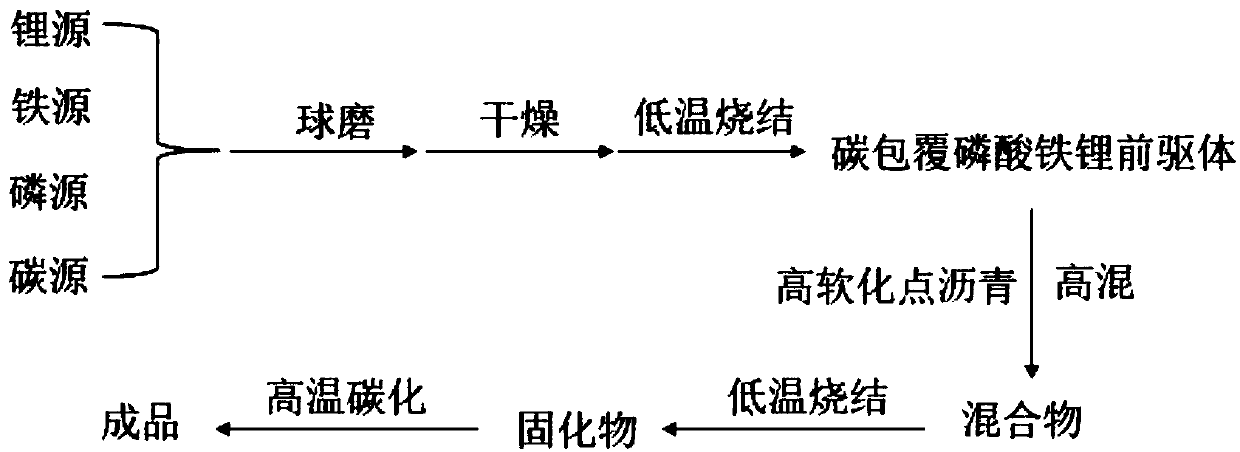

[0034] refer to figure 2 , a method for preparing a double-layer pitch carbon-coated lithium iron phosphate positive electrode material, comprising the steps of:

[0035] S1. Mix low softening point asphalt with a mixed solvent. The solvent is obtained by mixing water and ethanol at a volume ratio of 1:1; then add lithium acetate, iron phosphate and lithium dihydrogen phosphate in sequence, including lithium, iron and phosphorus The molar ratio of lithium iron phosphate is 1:1:1, the mass ratio of the theoretical synthesis amount of lithium iron phosphate to low softening point pitch is 1:0.002, then ball milled for 36 hours, dried at 95°C, and sintered at 400°C for 4 hours under the protection of xenon gas to obtain carbon Coated lithium iron phosphate calcined material;

[0036] S2. Mix carbon-coated lithium iron phosphate calcined material and high softening point pitch for 5 minutes at a mass ratio of 1:0.2, place in a rotary rotary kiln at a speed of 15 rpm, and place i...

Embodiment 2

[0038] A method for preparing a double-layer pitch carbon-coated lithium iron phosphate cathode material, comprising the steps of:

[0039] S1. Mix low softening point asphalt with a mixed solvent. The solvent is obtained by mixing water and glycerol at a volume ratio of 1:1; then add lithium oxide, ferric oxide and phosphoric acid in sequence, including lithium, iron and phosphorus The molar ratio of the elements is 1:1:1, the mass ratio of the theoretically synthesized amount of lithium iron phosphate to the low softening point pitch is 1:0.1, then ball milled for 8 hours, dried at 105°C, and sintered at 300°C for 10 hours under the protection of xenon gas to obtain Carbon-coated lithium iron phosphate calcined material;

[0040] S2. Mix carbon-coated lithium iron phosphate calcined material and high softening point pitch for 25 minutes at a mass ratio of 1:0.05, place in a rotary rotary kiln at a speed of 1 revolution / min, and place it in a neon gas atmosphere. Raise the t...

Embodiment 3

[0042] A method for preparing a double-layer pitch carbon-coated lithium iron phosphate cathode material, comprising the steps of:

[0043] S1. Add 4g of asphalt with low softening point (70-85°C) into the ceramic ball mill tank, use water / methanol (volume ratio: 1:1) as solvent, then add 9.37g of lithium carbonate, 45.6g of ferrous oxalate and 29.2g ammonium dihydrogen phosphate, the theoretical synthesis amount of lithium iron phosphate and the mass ratio of low softening point asphalt is 1:0.1; put the ball mill jar into a planetary ball mill for 24 hours, take it out and put it in a drying oven at 100°C for drying ; Then put it into a nitrogen-protected tube furnace and sinter at 400 ° C for 4 hours to obtain a carbon-coated lithium iron phosphate calcined product;

[0044] S2. Mix the above-mentioned carbon-coated lithium iron phosphate calcined product with high softening point (270-290°C) asphalt at a mass ratio of 1:0.2, mix in a high-speed mixer for 15 minutes, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com