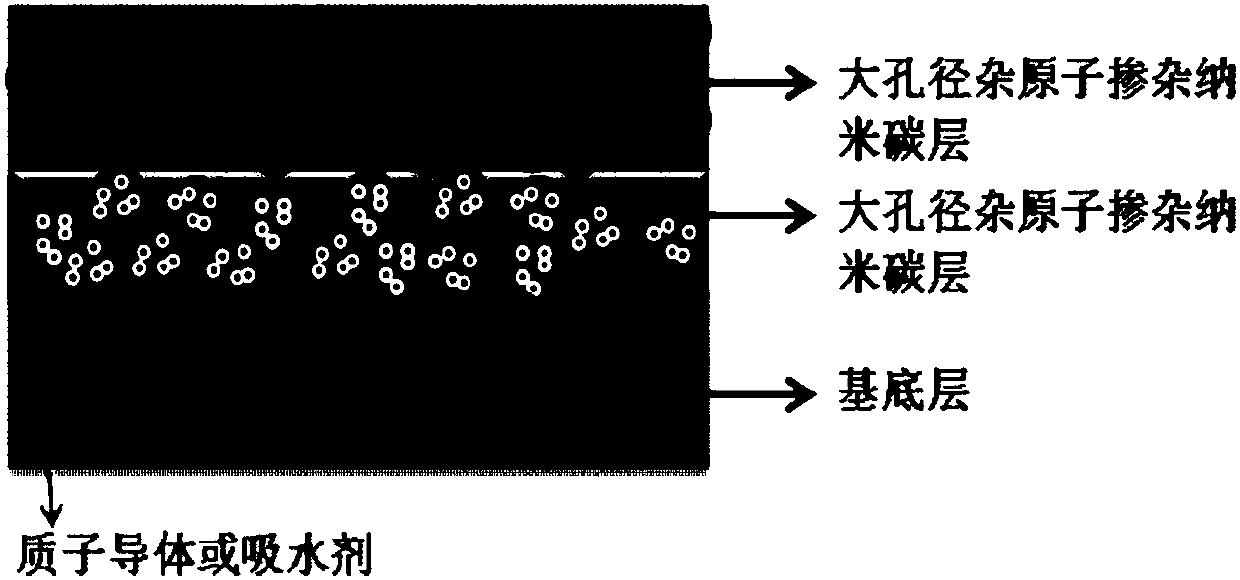

Negative electrode for electroreduction of carbon dioxide and preparation method thereof

A carbon dioxide and cathode technology, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of inapplicability, achieve the effects of improving selectivity and activity, increasing concentration, and reducing mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

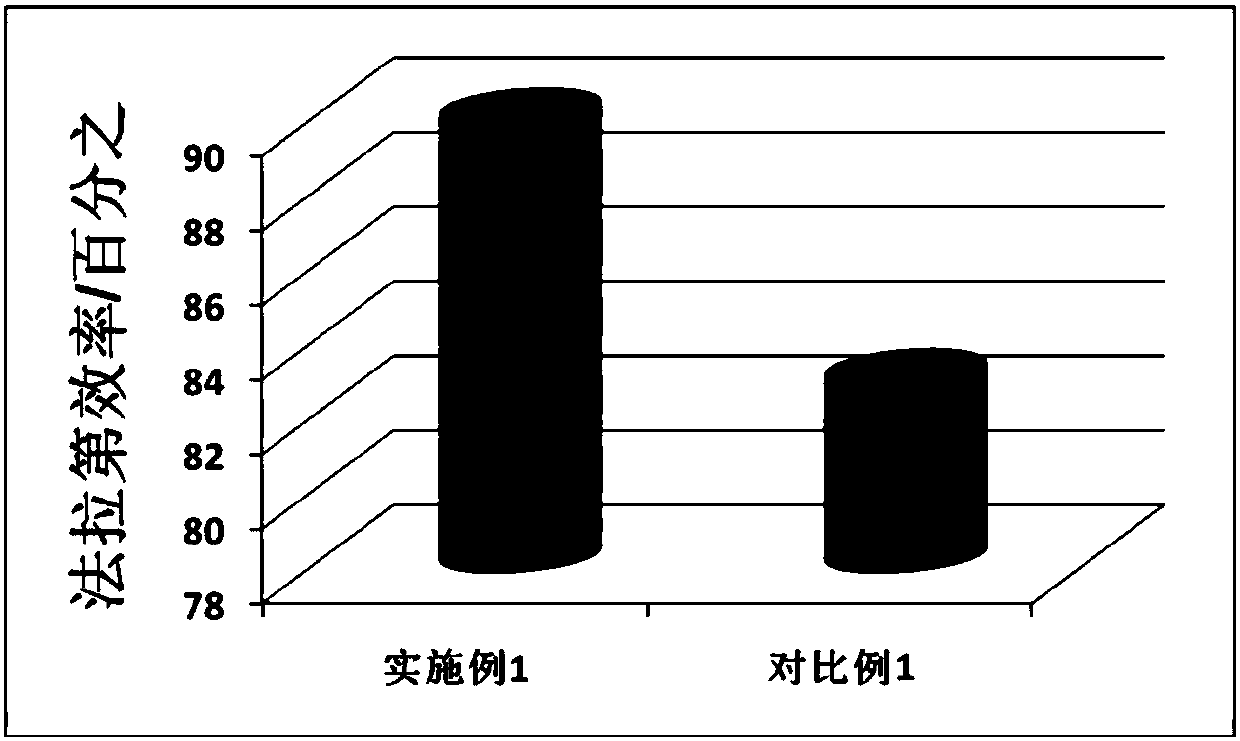

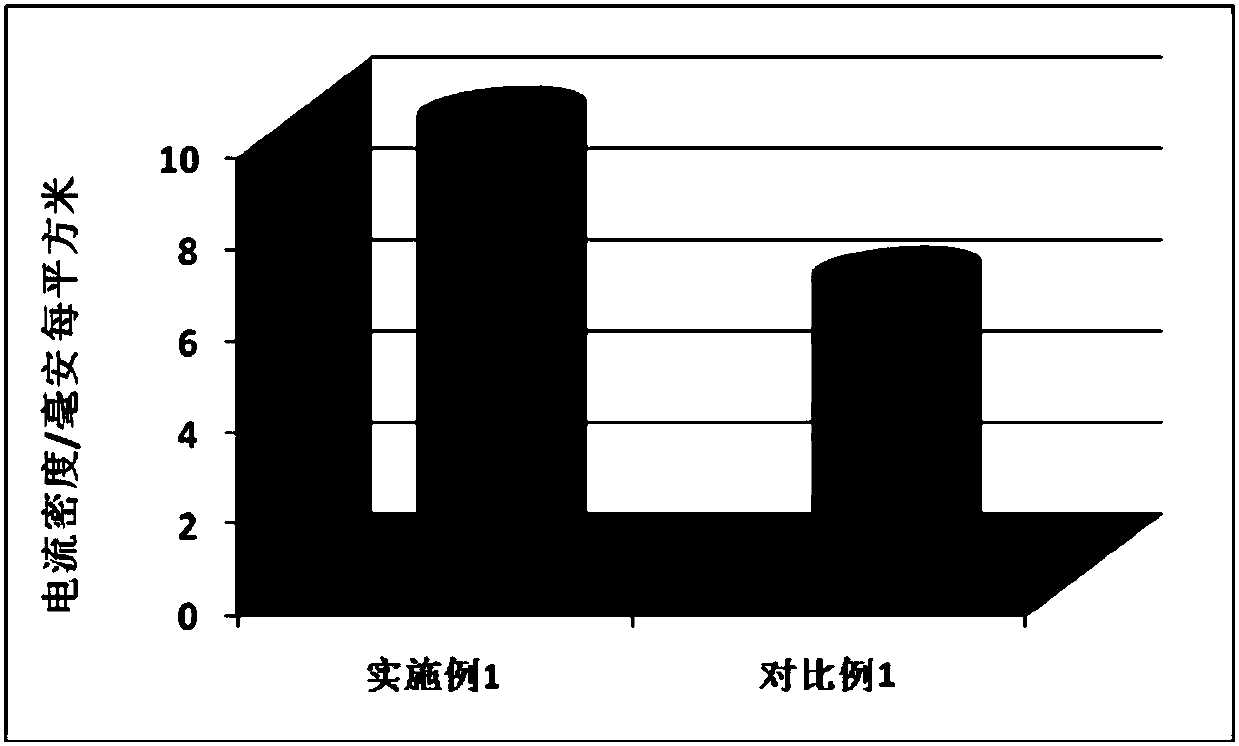

Embodiment 1

[0054] Nitrogen-doped nano-carbon materials were prepared using nano-calcium carbonate as a template. Accurately weigh 5g of sucrose, add 2g of ethylenediamine into 10ml of water and stir until completely dispersed, then add 5g of calcium carbonate, heat and mechanically stir in a water bath at 80°C to make it completely dispersed, and put it in a vacuum at 80°C after the water is completely evaporated Dry for 24h. Then put the dried product into high temperature tube furnace for carbonization, N 2 Treat at 850℃ for 3h, change CO 2 Purging at 850°C for 1 hour to obtain nanoparticle / carbon composites, then removing calcium carbonate with an appropriate amount of 2M dilute hydrochloric acid, and then vacuum drying at 80°C for 24 hours after filtration to obtain the macroporous nitrogen-doped nanocarbon material.

[0055] Dissolve 6.16 resorcinol in 7mL deionized water to form solution A; then dropwise add 8.4ml of formaldehyde solution with a mass concentration of 37% to form...

Embodiment 2

[0060] Nitrogen-doped nano-carbon materials were prepared using nano-calcium carbonate as a template. Accurately weigh 5g of sucrose, add 2g of ethylenediamine into 10ml of water and stir until completely dispersed, then add 5g of calcium carbonate, heat and mechanically stir in a water bath at 80°C to make it completely dispersed, and put it in a vacuum at 80°C after the water is completely evaporated Dry for 24h. Then put the dried product into high temperature tube furnace for carbonization, N 2 Treat at 850℃ for 3h, change CO 2 Purging at 850°C for 1 hour to obtain nanoparticle / carbon composites, then removing calcium carbonate with an appropriate amount of 2M dilute hydrochloric acid, and then vacuum drying at 80°C for 24 hours after filtration to obtain the macroporous nitrogen-doped nanocarbon material.

[0061] Dissolve 7.06g of melamine in 10mL of deionized water to form solution A; add dropwise 12.3ml of formaldehyde solution with a mass concentration of 37% to th...

Embodiment 3

[0064] P-doped nano-carbon materials were prepared using nano-alumina as a template. Accurately weigh 3.15g of melamine, 5.0ml of formaldehyde solution, 10ml of water, stir at 85°C for 20min until completely dissolved into a transparent state, then add 4g of alumina after 0.2g of triphenylphosphine, heat in a water bath at 80°C and Stir mechanically to make it completely dispersed, and put it into vacuum drying at 60°C for 24 hours after the water is completely evaporated. Then put the dried product into a high-temperature tube furnace for carbonization, the atmosphere is nitrogen, and the gas flow is controlled at 20ml / min. Take out at 900 DEG C by carbonization for 2 hours to obtain the nanoparticle / carbon composite, remove the nano-alumina with an appropriate amount of 2M dilute hydrochloric acid, and vacuum dry at 80 DEG C for 24 hours after filtration to obtain the P-doped macroporous carbon material (phosphorus content 0.9%).

[0065] Dissolve 7.06g of melamine in 10mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com