High-burning rate gas generating agent and granulation method thereof

A gas generating agent and process technology, which is used in the production of compressed gas, attack equipment, explosives, etc., can solve the problems of large fluctuations in the combustion performance of the agent, slow combustion speed of the gas generating agent, and high manufacturing costs, and achieve simple and easy processes. Operation, avoid the effect of crushing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

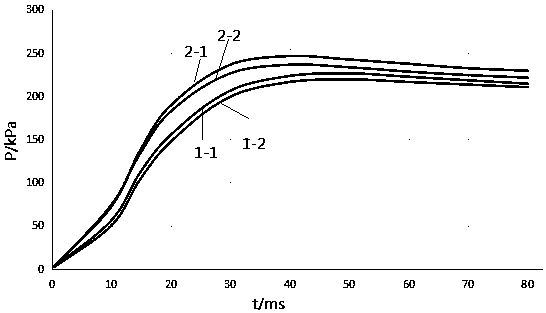

Embodiment 1

[0035] 60 kilograms of guanidine nitrate; 80 kilograms of basic copper nitrate with a solid content of 10% W; 10 kilograms of ammonium perchlorate; 10 kilograms of copper oxide. Add these components into the heating reactor and start heating. After the temperature reaches 70°C, use a basket sand mill to disperse for 1 minute to obtain the material, keep the material temperature at 70°C, use a double-flow spray granulator to dry the material, and spray granulate The air inlet temperature of the machine is 80°C, the fan frequency is 50HZ, and the nozzle diameter is 5mm to obtain dry particles 1. Use a conical granulator to pass the particles 1 through a 60-mesh sieve to obtain particles 2. Use a vibrating fluidized bed for the particles 2. Dried in a dryer until the final water content is not more than 0.5% W, and finally compressed into a cylindrical tablet with an outer diameter of 4 mm and an inner diameter of 1 mm using a rotary tablet press.

Embodiment 2

[0037] 20 kg of guanidine nitrate; 50 kg of basic copper nitrate with a solid content of 60% W; 15 kg of 5-aminotetrazole (5AT); 5 kg of potassium perchlorate and 300 kg of water. Add these components into the reaction kettle and start heating. After the temperature reaches 90°C, use a basket sand mill to disperse for 5 hours to obtain the material, keep the material temperature at 90°C, use a double-flow spray granulator to dry the material, and use a three-flow spray granulator. The granulator dries the material, the air inlet temperature of the spray granulator is 150°C, the fan frequency is 1HZ, the nozzle diameter is 2mm, and the dried particles 1 are obtained, and the particle 1 is passed through a 20-mesh sieve by a vibrating screen to obtain the particle 2, and the belt type is used. The particles 2 are dried in a vacuum dryer until the final water content is no more than 0.1% W, and finally compressed into a cylindrical tablet with a diameter of 6 mm using an oil press...

Embodiment 3

[0039] 30 kilograms of guanidine nitrate; 65 kilograms of solid content are basic copper nitrate of 45% W, 150 kilograms of water. Add these components into the reaction kettle and start heating. After the temperature reaches 80°C, use a basket sand mill to disperse for 30 minutes to obtain the material, keep the material temperature at 80°C, use a three-flow spray granulator to dry the material, and use a double-flow spray granulator. The granulator dries the material, the air inlet temperature of the spray granulator is 110°C, the fan frequency is 25HZ, the nozzle diameter is 2mm, and the dried granule 1 is obtained, and the granule 1 is passed through a 30-mesh sieve by a conical granulator to obtain the granule 2, The particle 2 is dried to a final water content of not more than 0.1% W using a belt vacuum dryer, and finally pressed into a circular tablet with an outer diameter of 5 mm and an inner diameter of 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com