Pressure measurement sensitivity adjustment method

An adjustment method and technology of sensitivity, applied in the direction of fluid pressure measurement, measurement force, and measurement device by changing ohmic resistance, can solve problems such as changing and reducing strength, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawings and examples.

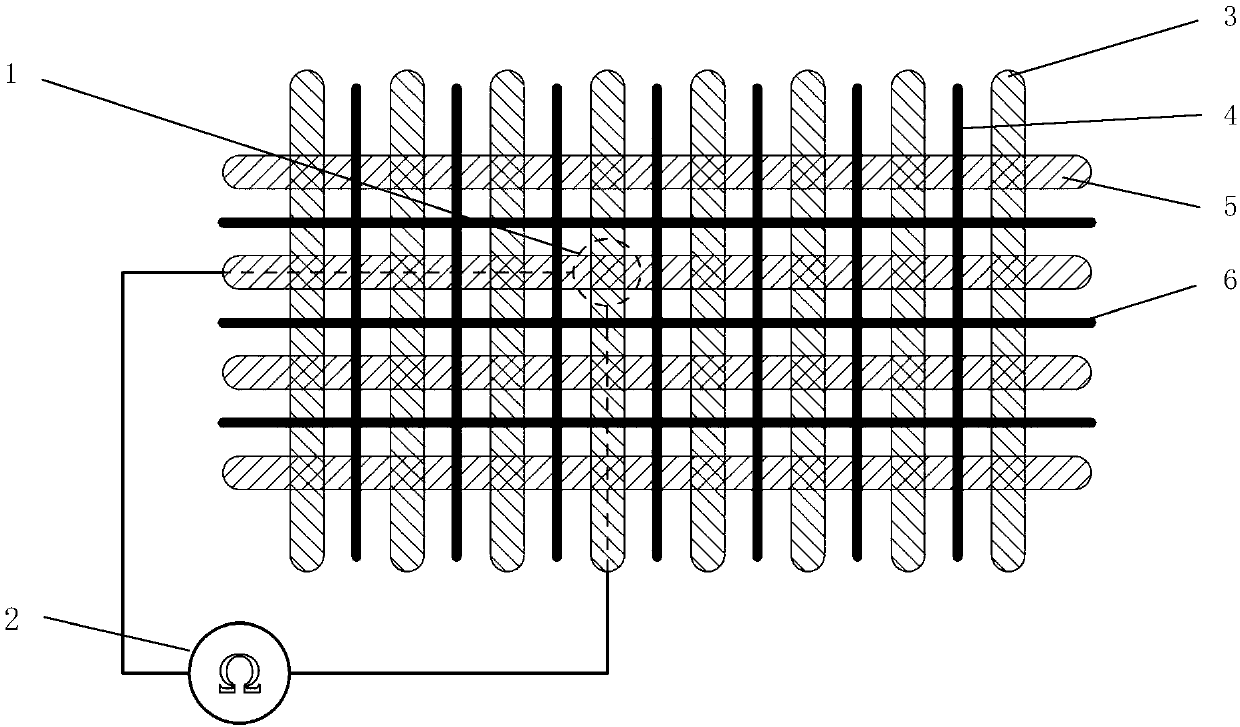

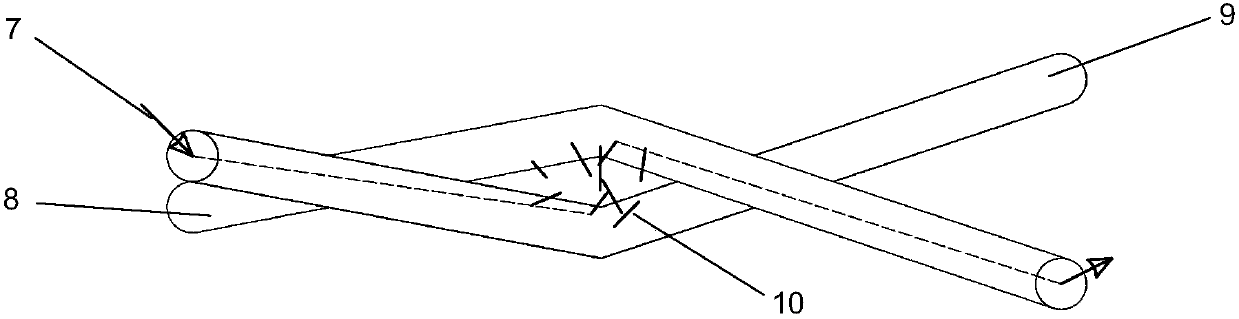

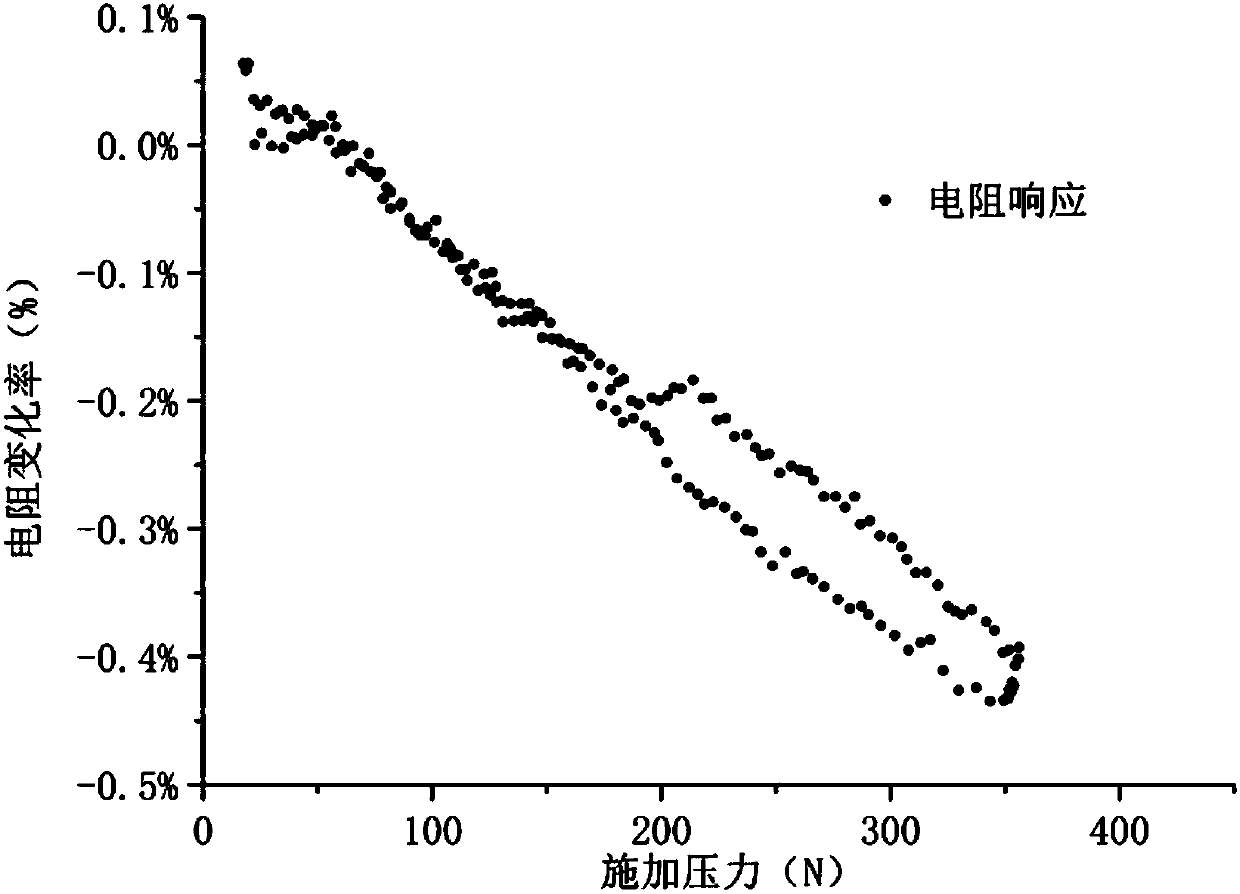

[0020] A typical example of the inventive method is: adopt the three-dimensional weaving method to manufacture the multi-layer composite fiber fabric that has binding yarn, as figure 1 As shown, the middle layer of the fabric uses Toray T700-12K carbon fiber as a sensitive fiber except for some warp and weft yarns, and the other fibers are Kevlar-29. The polymer matrix adopts vinyl resin RF1001, and the conductive filler adopts multi-walled carbon nanotubes (outer diameter 50 nanometers, length 10-20 microns).

[0021] In the fabric manufacturing stage, adjust the tension control spring of the yarn carrier so that the yarn tension of all warp and weft yarns is controlled at 80 centinewtons, and verify the actual tension of each yarn with a hand-held yarn tension tester.

[0022] In the polymer matrix preparation stage, the dosage of each material is: the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com