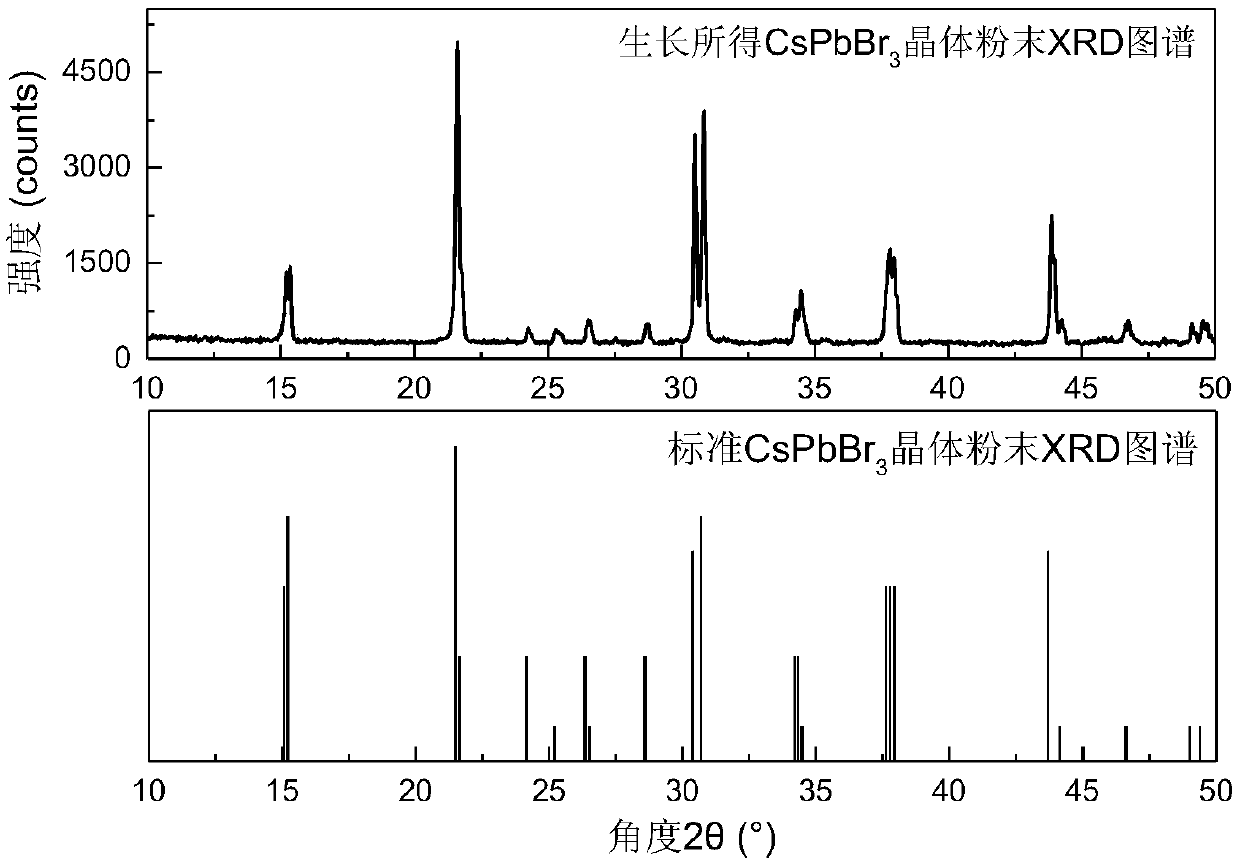

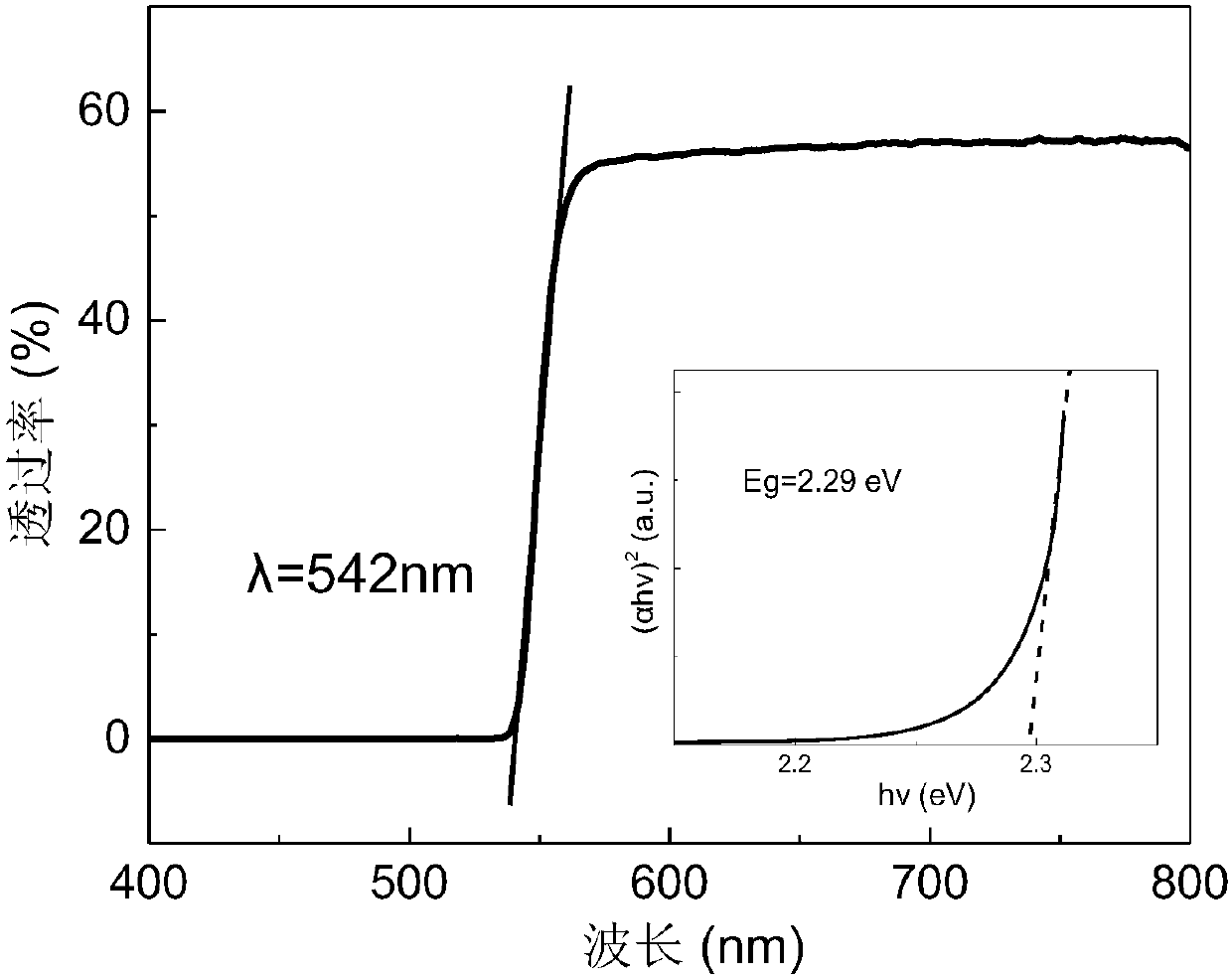

Temperature inversion solution growth method of all-inorganic perovskite single crystals

A solution growth, inorganic calcium technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as poor practicability, and achieve the effect of good crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the first step, 0.05 mol of cesium bromide with a concentration of 99.99% and 0.1 mol of lead bromide with a concentration of 99.99% are added to 100 mL of organic solvent dimethyl sulfoxide, and stirred at room temperature for 1 hour, until the solid is completely dissolved A clear solution was obtained.

[0022] In the second step, filter the above-obtained clear solution with a filter syringe, add the inverse solubility mixture, and stir well to obtain a precursor solution. The reverse solubility mixture is prepared by mixing cyclohexanol and dimethylformamide in a volume ratio of 1:1.8. The volume of the inverse solubility mixture added was 100 mL.

[0023] In the third step, place the precursor solution in a flat-bottomed flask with a clean bottom and seal it. Fix the flask on the fixing clamp and adjust the height so that it is completely immersed in the heating water tank. After keeping it in a water bath at 50°C for 10 hours, fine crystals precipitated on the b...

Embodiment 2

[0026] In the first step, 0.06 mol of cesium bromide with a concentration of 99.99% and 0.12 mol of lead bromide with a concentration of 99.99% are added to 120 mL of organic solvent dimethyl sulfoxide, and stirred at room temperature for 2 hours, until the solid is completely dissolved A clear solution was obtained.

[0027] In the second step, filter the above-obtained clear solution with a filter syringe, add the inverse solubility mixture, and stir well to obtain a precursor solution. The inverse solubility mixture is prepared by mixing cyclohexanol and dimethylformamide in a volume ratio of 1:1.7. The volume of the added reverse solubility mixture was 120 mL.

[0028] In the third step, place the precursor solution in a flat-bottomed flask with a clean bottom and seal it. Fix the flask on the fixing clamp and adjust the height so that it is completely immersed in the heating water tank. After being kept in a water bath at 49.5°C for 11 hours, a few fine crystals precipitate...

Embodiment 3

[0031] In the first step, 0.08 mol of cesium bromide with a concentration of 99.99% and 0.16 mol of lead bromide with a concentration of 99.99% are added to 160 mL of organic solvent dimethyl sulfoxide, and stirred at room temperature for 3 hours, until the solid is completely dissolved A clear solution was obtained.

[0032] In the second step, filter the above-obtained clear solution with a filter syringe, add the inverse solubility mixture, and stir well to obtain a precursor solution. The inverse solubility mixture is prepared by mixing cyclohexanol and dimethylformamide in a volume ratio of 1:1.5. The volume of the added reverse solubility mixture was 160 mL.

[0033] In the third step, place the precursor solution in a flat-bottomed flask with a clean bottom and seal it. Fix the flask on the fixing clamp and adjust the height so that it is completely immersed in the heating water tank. After keeping it in a water bath at 49°C for 12 hours, a few fine crystals precipitated ...

PUM

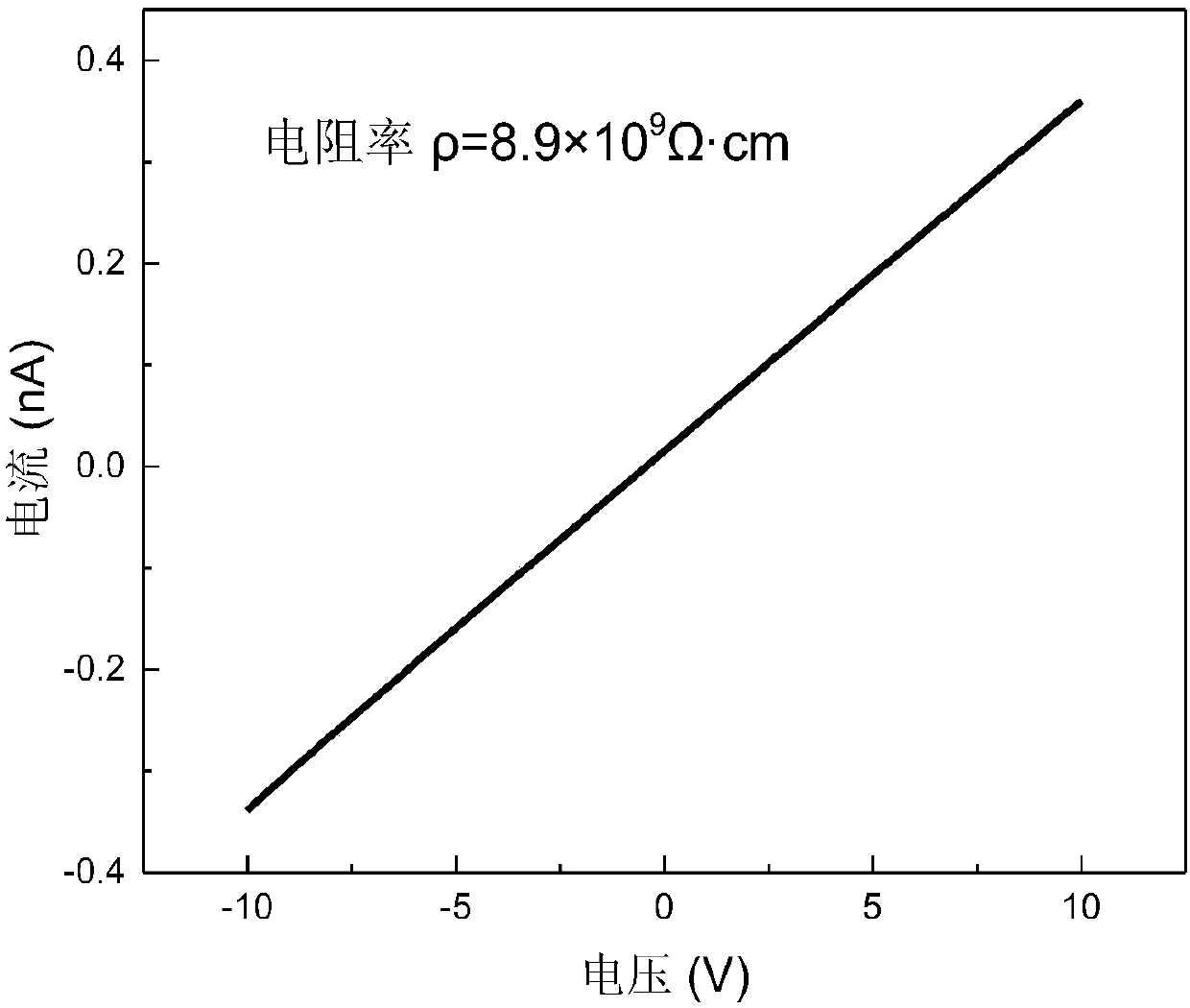

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com