Release type hardening membrane

A hardened film and release technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the failure of shared bicycle smart locks and GPS positioning functions, affect the solar panel to receive "sunshine, affect the shared bicycle power generation system, etc." problem, to achieve excellent scratch resistance, high hardness, and the effect of preventing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

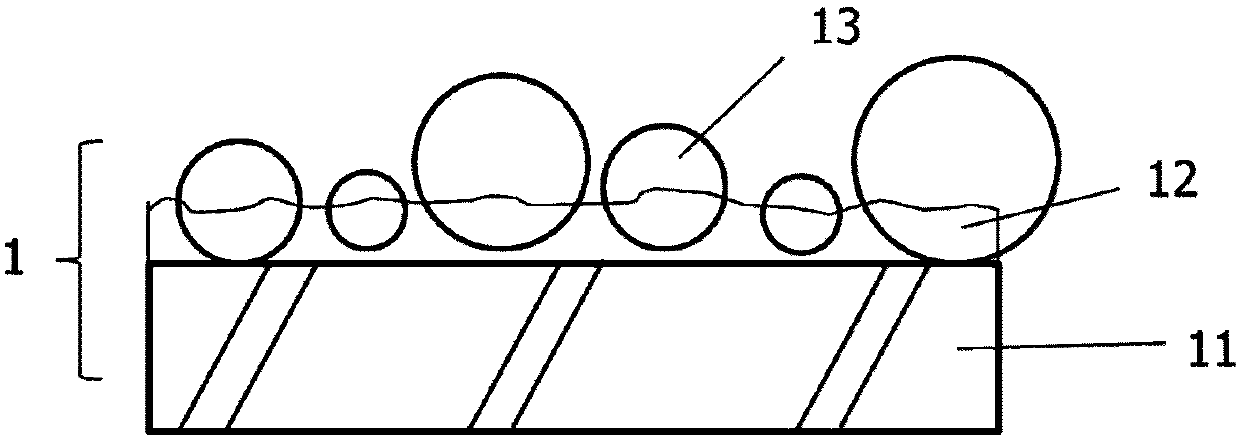

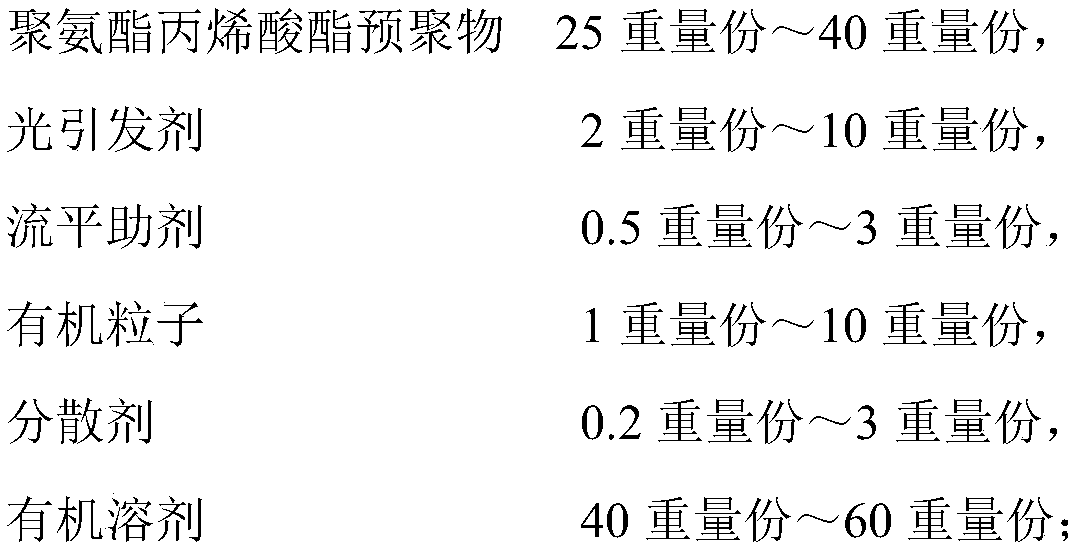

[0035] With 25.0g hexafunctional aromatic urethane acrylate prepolymer (Sinlimei Technology Co., Ltd., trade name: 670A2, functionality: 6), 10.0g photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: 184 ), 3.0g of leveling aid (BYK-UV3570, the molecular weight of the siloxane structure accounts for 80% of the molecular weight of the leveling aid), 10.0g of organic particles (polystyrene PS, particle size D1 is 15μm), 3.0 g of dispersant (BYK-111) and 49.0 g of ethanol were placed in a stirring pot, and stirred evenly to obtain a coating material.

[0036] The coating solution is coated on one side of a polycarbonate film with a thickness of 250 μm, dried for 3 minutes at an oven temperature of 120° C. 2 The coating was cured by UV light to obtain a matte hard coating with a coating thickness D2 of 3 μm. The evaluation results are listed in Table 1.

Embodiment 2

[0038]With 40.0g hexafunctionality aliphatic urethane acrylate prepolymer (Xinlimei Technology Co., Ltd., trade name: 230A2, functionality: 6), 2.0g photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: TPO ), 0.5g of leveling aid (BYK-371, the molecular weight of the siloxane structure accounts for 70% of the molecular weight of the leveling aid), 1.0g of organic particles (polymethyl methacrylate PMMA, particle size D1 is 16 μm), 0.2 g of dispersant (BYK-2008) and 56.3 g of methyl ethyl ketone were placed in a stirring pot, and stirred evenly to obtain a coating material.

[0039] Apply the coating solution to one side of a polyethylene terephthalate film with a thickness of 188 μm, dry it for 3 minutes at an oven temperature of 120° C. 2 The coating was cured by UV light to obtain a matte hard coating with a coating thickness D2 of 6 μm. The evaluation results are listed in Table 1.

Embodiment 3

[0041] 31.0g nine-functionality aliphatic urethane acrylate prepolymer (Sartomer, trade name: CN9013NS, functionality: 9), 5.0g photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: 1173), 2.0 g of leveling aid (BYK-3710, the molecular weight of the siloxane structure accounts for 90% of the molecular weight of the leveling aid), 1.5g of organic particles (polybutyl methacrylate PBMA, particle size D1 is 17.5 μm) , 0.5 g of dispersant (BYK-2000) and 60.0 g of ethyl acetate were placed in a stirring pot, and stirred evenly to obtain a coating material.

[0042] Apply the coating liquid on one side of a polymethyl methacrylate film with a thickness of 500 μm, dry it for 3 minutes at an oven temperature of 120° C. 2 The coating was cured by UV light to obtain a matte hard coating with a coating thickness D2 of 3.5 μm. The evaluation results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com