Preparation method of flat glass with anti-glare and anti-reflection functions

A flat glass and functional technology, which is applied in the field of preparation of flat glass with anti-glare and anti-reflection functions, can solve the problems of high cost of patents and environmental protection, adverse environmental impact of fluorine-containing waste liquid, etc., and achieve increased visible light transmittance and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. The glass is cut, edged, cleaned, dried, and placed on a special glass shelf after passing the inspection;

[0024] 2. Add water, glycerol, ethylenediamine and sodium carbonate to the reaction kettle in sequence according to the formula. The molar ratio is: water: glycerol: ethylenediamine: sodium carbonate = 55.6:0.08:0.001:0.6, and stir evenly;

[0025] 3. Put the glass frame together into the reaction kettle, and close the kettle door. Reactor temperature controller setting temperature is 110 DEG C, deflates and cools down after 10 hours of reaction;

[0026] 4. Open the kettle door, take out the glass from the rack, first rinse the attachments on the glass surface with tap water, then clean and dry the glass, and inspect the packaging.

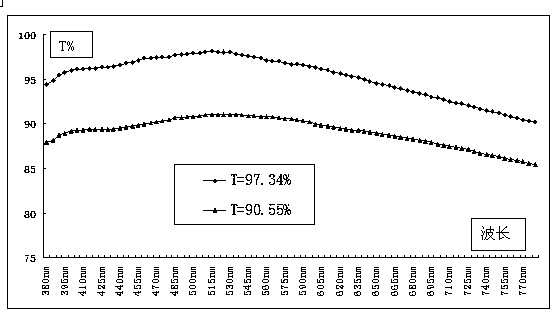

[0027] The visible light transmittance contrast curve of the anti-reflection glass of this embodiment and the glass substrate without anti-reflection treatment is as follows figure 1 Shown, the SEM figure of this embodiment gla...

Embodiment 2

[0029] 1. The glass is cut, edged, cleaned, dried, and placed on a special glass shelf after passing the inspection;

[0030] 2. Add water, glycerol, ethylenediamine and sodium carbonate to the reaction kettle in sequence according to the formula. The molar ratio is: water: glycerol: ethylenediamine: sodium carbonate = 55.6:0.08:0.001:0.9, and stir evenly;

[0031] 3. Put the glass frame together into the reaction kettle, and close the kettle door. Reactor temperature controller setting temperature is 110 DEG C, deflates and cools down after 10 hours of reaction;

[0032] 4. Open the kettle door, take out the glass from the rack, first rinse the attachments on the glass surface with tap water, then clean and dry the glass, and inspect the packaging.

[0033] The SEM image of the porous structure layer on the glass surface of this embodiment is as follows image 3 As shown, the SEM image of the cross-section of the porous structure layer on the glass surface is as follows F...

Embodiment 3

[0035] 1. The glass is cut, edged, cleaned, dried, and placed on a special glass shelf after passing the inspection;

[0036] 2. Add water, glycerol, ethylenediamine and sodium carbonate to the reaction kettle in sequence according to the formula, the molar ratio is: water: glycerol: ethylenediamine: sodium carbonate = 55.6:0.08:0.001:1.2, and stir evenly;

[0037] 3. Put the glass frame together into the reaction kettle, and close the kettle door. Reactor temperature controller setting temperature is 110 DEG C, deflates and cools down after 10 hours of reaction;

[0038] 4. Open the kettle door, take out the glass from the rack, first rinse the attachments on the glass surface with tap water, then clean and dry the glass, and inspect the packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com