Crystal silicon cell double-layer passivation anti-reflection structure

A crystalline silicon battery and double-layer film technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large incident light loss, single-layer film anti-reflection effect and passivation effect are not very ideal, so as to reduce reflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

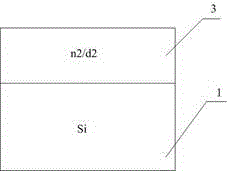

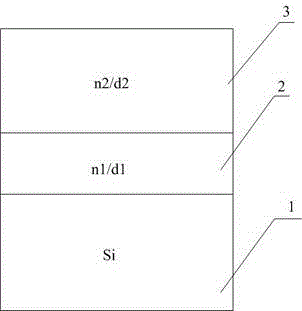

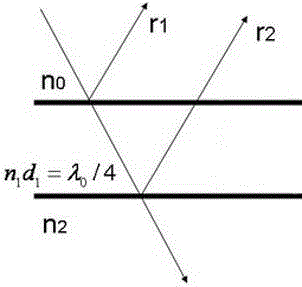

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. The double-layer passivation antireflection structure of the crystalline silicon cell is characterized in that: the surface of the crystalline silicon cell 1 is coated with two layers of silicon nitride films, the lower layer of silicon nitride film 2 and the lower layer of silicon nitride film above the crystalline silicon cell 1 2 above the upper silicon nitride film 3, the thickness of the lower silicon nitride film 3 is d 2 , the refractive index n 2 , the thickness d of the upper silicon nitride film 3 1 , the refractive index n 1 , and d 1 >d 2 , n 1 2 ; the n 1 , n 2 、d 2 The relationship is n 1 2 =n 0 no 2 , where n 0 is the refractive index of air, n 1 d 1 =λ 0 / 4, λ 0 is the wavelength of the incident light. Because the refractive index of the lower silicon nitride film 2 is large, and its own extinction coefficient is large, it will absorb part of the short wave,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com