Preparation method of regularly-bent tellurium nanowires

A tellurium nanowire and bending technology, which is applied in the field of shape-controllable preparation of semiconductor nanomaterials, can solve the problem of single shape of tellurium nanowires, and achieve the effects of simple reaction, maintenance of pH, and optimization of experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

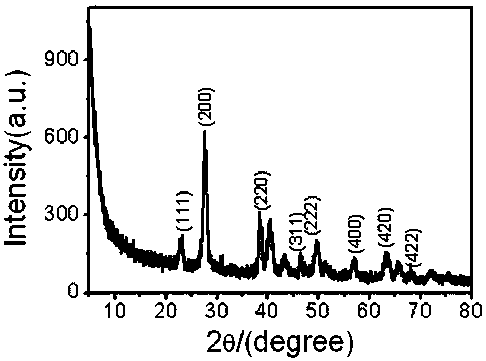

[0029] Weigh 0.1 g of sodium tellurite, dissolve it in 100 ml of deionized water magnetized by a magnetic field with a field strength of 2 T, and stir evenly to obtain solution A; under stirring conditions, add 5 g of Octyltrimethylammonium chloride, continue to stir to obtain solution B; transfer the obtained solution B to a three-necked flask, place the three-necked flask in an oil bath at 100°C for heating and stirring, then add 15ml of hydrazine hydrate and At the same time, feed nitrogen into the reaction bottle to maintain the inert atmosphere of the reaction system, and the nitrogen flow rate is controlled at 100ml / min; under constant stirring, after 30min, stop the reaction, place the reaction bottle in cold water and drop to room temperature, and you can get Final rule-bent tellurium nanowires.

Embodiment 2

[0031] Weigh 0.1 g of tellurium dioxide, dissolve it in 100 ml of deionized water magnetized by a magnetic field with a field strength of 3 T, and stir evenly to obtain solution A; Alkyltrimethylammonium chloride, continue to stir to obtain solution B; transfer the obtained solution B to a three-necked flask, place the three-necked flask in an oil bath at 110°C for heating and stirring, then add 15ml of hydrazine hydrate and simultaneously Feed nitrogen into the reaction bottle to maintain the inert atmosphere of the reaction system, and the nitrogen flow rate is controlled at 100ml / min; under constant stirring, after 30min, stop the reaction, place the reaction bottle in cold water and drop it to room temperature to obtain the final Regularly curved tellurium nanowires.

Embodiment 3

[0033] Weigh 0.5g of tellurium dioxide, dissolve it in 200ml of deionized water magnetized by a magnetic field with a field strength of 3T, and stir evenly to obtain solution A; Alkyltrimethylammonium chloride, continue to stir to obtain solution B; The solution B obtained is transferred in the three-necked flask, and the three-necked flask is placed in an oil bath at 120°C for heating and stirring, then 10ml of HI is added and simultaneously Nitrogen was introduced into the reaction bottle to maintain the inert atmosphere of the reaction system, and the flow rate of nitrogen gas was controlled at 150ml / min; under constant stirring, after 60 minutes, the reaction was stopped, and the reaction bottle was placed in cold water to cool down to room temperature, and the final rule was obtained. Bent tellurium nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com