Super-thick carbon oil printing special composite screen printing plate and manufacturing method thereof

A technology of composite screen and production method, applied in printing, printing plate preparation and other directions, can solve the problems of carbon oil leakage short circuit, uneven carbon oil, printing offset oil leakage, etc., to achieve neat and smooth edges of carbon oil, printing quality Guaranteed, graphically smooth results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments.

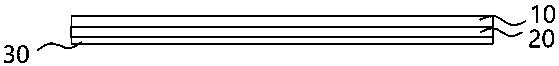

[0018] see figure 1 , the special composite screen for ultra-thick carbon oil printing according to the present invention is composed of a basic screen 10, a water film layer 20, and a photosensitive paste layer 30. Among them, the basic screen adopts a composite steel mesh, and a water film layer is arranged on the back of the composite steel mesh, and a photosensitive paste layer is coated on the water film layer.

[0019] The manufacturing method of the special-purpose composite screen is as follows: first, select a composite steel mesh with a mesh number of 150-200, fully wet the composite steel mesh with water, then attach a layer of water film on the back of the composite steel mesh, and put it into an oven Baking, the baking is controlled at 50-60 ° C, and baking is done for 20 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com