Super hybrid laminated composite structure and preparation method thereof

A layered composite and ultra-hybrid technology, which is applied in the direction of metal layered products, layered product processing, chemical instruments and methods, etc., can solve the problem that the stiffness cannot meet the performance requirements of rail transit, cannot meet the changing environment of rail transit, and Corrosion and labor problems, to achieve high practical engineering application possibility and value, improve fatigue resistance and damage tolerance, and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

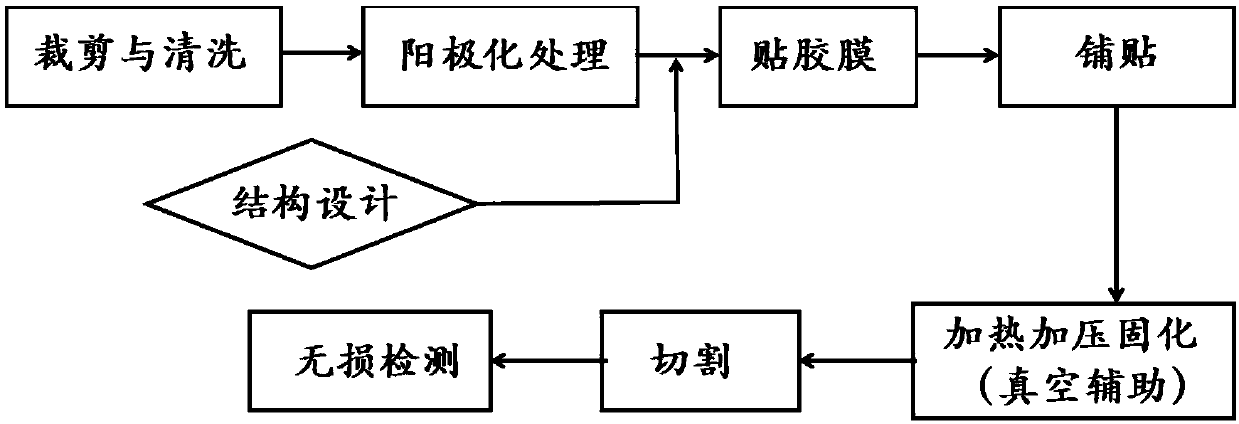

Method used

Image

Examples

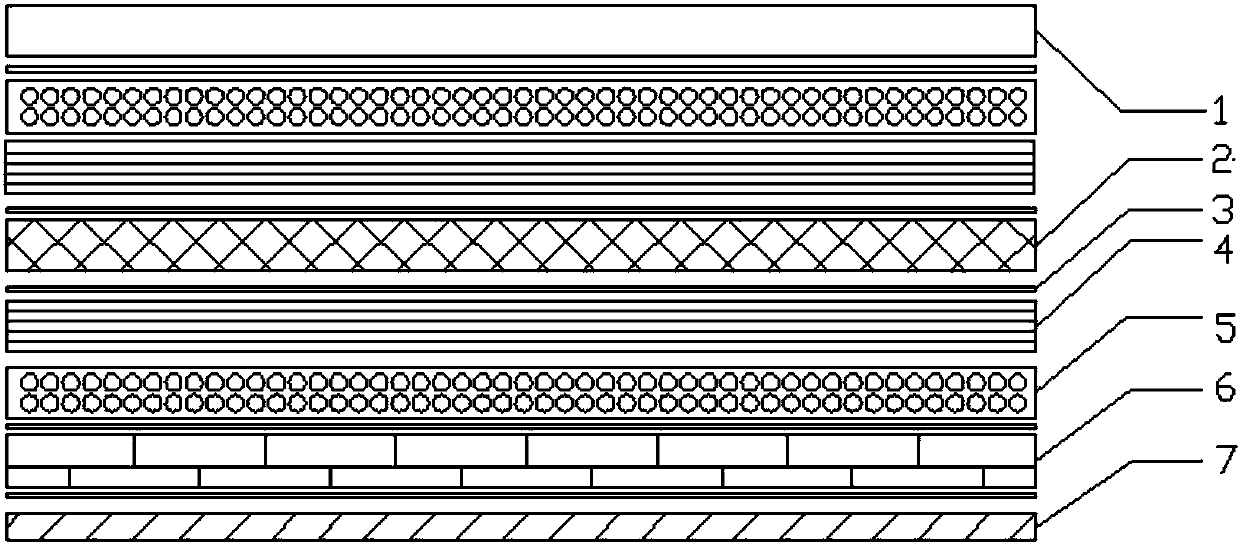

specific Embodiment 1

[0033] Step 1: For the ultra-hybrid layered composite structure of 2024 aluminum alloy-glass fiber-aramid paper honeycomb-nonwoven composite knitted felt, first select 0.3mm thick 2024 aluminum alloy, glass fiber, which contains PP resin, and the pore size is 6mm aramid paper honeycomb and 2mm thick non-woven composite needle felt, the fiber layer is hemp fiber. Cut the 2024 aluminum alloy layer, fiber layer, aramid paper honeycomb layer, non-woven composite needle felt layer and fabric layer into 300×300mm, and then clean the surface of the 2024 aluminum alloy layer with alcohol.

[0034] Step 2: Alkaline wash the 2024 aluminum alloy layer for 1 minute, the solute of the alkali washing solution is NaOH, Na 2 CO 3 , where the density is 30g / L respectively, then rinsed with tap water for 5min, and then pickled, the solute of pickling is HNO 3 , where the density is 400g / L, then rinse with tap water for 5 minutes. Finally, the 2024 aluminum alloy layer was anodized with phosp...

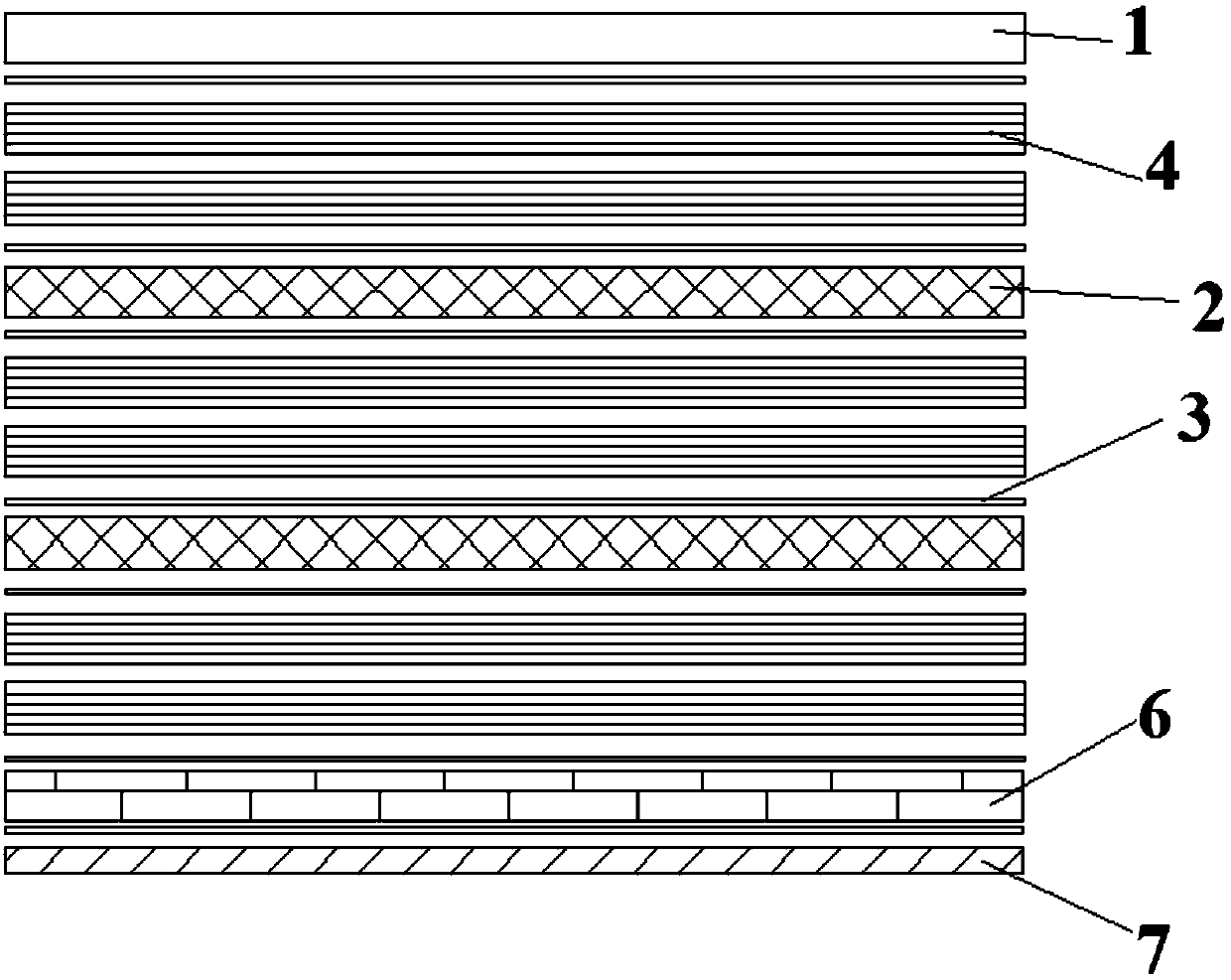

specific Embodiment 2

[0040] The first step: for the 6061 aluminum alloy-carbon fiber-glass fiber three-dimensional three-dimensional fabric-nonwoven needle felt layer super-hybrid layered composite structure, first select 0.3mm thick 6061 aluminum alloy, carbon fiber, which contains PP polypropylene resin, and the aperture Glass fiber three-dimensional fabric with a size of 8mm and a non-woven composite needle felt with a thickness of 2.5mm, and the reinforcing fiber is bamboo fiber. Cut the 6061 aluminum alloy layer, carbon fiber layer, glass fiber three-dimensional fabric layer, non-woven composite needle felt layer and fabric layer into 400×400mm, and then clean the surface of the 6061 aluminum alloy layer with acetone.

[0041] Step 2: Wash the 6061 aluminum alloy layer with alkali for 1.5 minutes, the solute of the alkali washing solution is NaOH, Na 2 CO 3 , where the density is 30g / L respectively, then rinse with tap water for 8min, and then carry out pickling, the solute of pickling is HN...

specific Embodiment 3

[0047] The first step: for the ultra-hybrid layered composite structure of aluminum-lithium alloy-aramid fiber-aluminum honeycomb-non-woven needle-punched felt layer, first select 0.3mm thick aluminum-lithium alloy, aramid fiber, which contains PP (polypropylene) Resin, aluminum honeycomb with a pore size of 10 mm and a non-woven composite needle-punched felt layer with a thickness of 3 mm, and the reinforcing fiber is hemp fiber. Cut the aluminum-lithium alloy layer, aramid fiber layer, aluminum honeycomb layer, non-woven composite needle-punched felt layer and fabric layer into 500×500mm, and then clean the surface of the aluminum-lithium alloy layer with alcohol.

[0048] Step 2: Alkaline-washing the aluminum-lithium alloy layer first, then rinsing with tap water, then pickling, and rinsing with tap water. The aluminum-lithium alloy layer was subjected to phosphoric acid anodization for 30 minutes, then rinsed for 10 minutes and dried;

[0049] The third step: select the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com