Protective film for chip cutting as well as preparation method and use method thereof

A technology for protective films and chips, applied in pressure-sensitive films/sheets, film/sheet-like adhesives, adhesive types, etc. The effect of small time change, high weather resistance and high material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

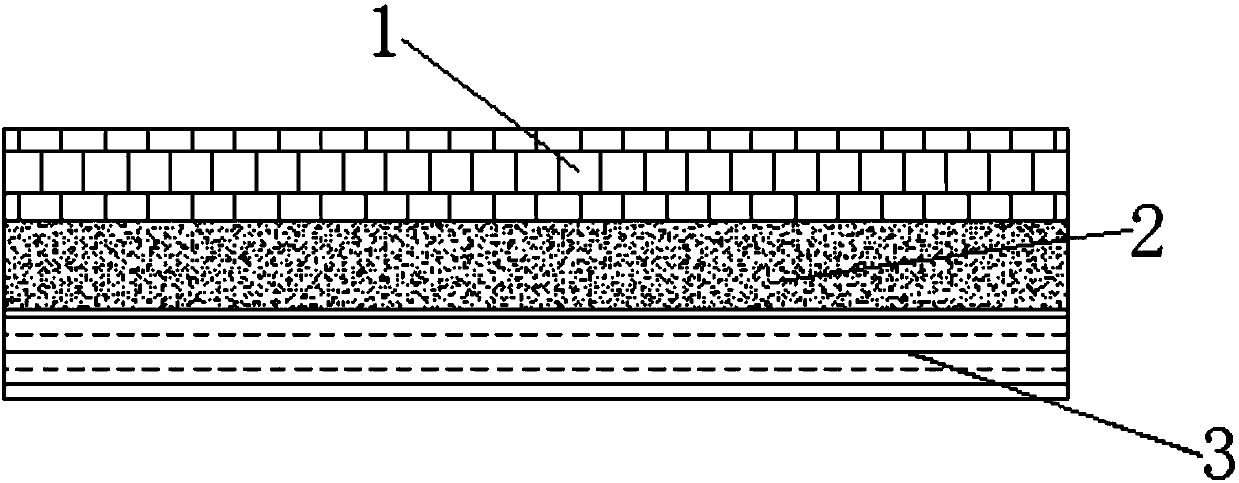

[0030] Such as figure 1 As shown, a protective film for chip dicing in this embodiment includes a release layer 1, a substrate layer 2 and an adhesive layer 3 in sequence, the substrate layer 2 is made of a modified PO material, and the modified PO material is made of PP and PE Copolymerized, the modified PO material includes, by weight, 50 parts of PP, 40 parts of PE, and 10 parts of talcum powder.

[0031] Wherein, the substrate layer 2 is a three-layer co-extruded structure, the thickness of the substrate layer 2 is 50 μm, including an inner layer, a core layer and an outer layer respectively made of a modified PO material, the thickness of the inner layer is 5 μm, and the thickness of the core layer is 5 μm. The thickness is 40 μm, and the thickness of the outer layer is 5 μm. The strength of the substrate layer 2 is 20N / mm 2 . The modified PO material of the inner layer also includes 0.5 parts by weight of a strong polar additive, which can improve the adhesion between...

Embodiment 2

[0044] Such as figure 1 As shown, a protective film for chip dicing in this embodiment includes a release layer 1, a substrate layer 2 and an adhesive layer 3 in sequence, the substrate layer 2 is made of a modified PO material, and the modified PO material is made of PP and PE Copolymerized, the modified PO material includes, by weight, 70 parts of PP, 20 parts of PE, and 10 parts of talcum powder.

[0045] Wherein, the substrate layer 2 is a three-layer co-extruded structure, the thickness of the substrate layer 2 is 100 μm, including an inner layer, a core layer and an outer layer respectively made of a modified PO material, the thickness of the inner layer is 10 μm, and the thickness of the core layer is 100 μm. The thickness is 80 μm, and the thickness of the outer layer is 10 μm. The strength of the substrate layer 2 is 50N / mm 2 . The modified PO material of the inner layer also includes 2 parts by weight of a strong polar additive, which can improve the adhesion betw...

Embodiment 3

[0053] Such as figure 1 As shown, a protective film for chip dicing in this embodiment includes a release layer 1, a substrate layer 2 and an adhesive layer 3 in sequence, the substrate layer 2 is made of a modified PO material, and the modified PO material is made of PP and PE Copolymerized, the modified PO material includes, by weight, 60 parts of PP, 35 parts of PE, and 5 parts of talcum powder.

[0054] Wherein, the substrate layer 2 is a three-layer co-extruded structure, the thickness of the substrate layer 2 is 80 μm, including an inner layer, a core layer and an outer layer respectively made of a modified PO material, the thickness of the inner layer is 10 μm, and the thickness of the core layer is 10 μm. The thickness is 60 μm, and the thickness of the outer layer is 10 μm. The strength of the substrate layer 2 is 40N / mm 2 . The modified PO material of the inner layer also includes 1.5 parts by weight of a strong polar additive, which can improve the adhesion betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com