Solar panel selective heat absorption material and preparation method thereof

A technology of heat-absorbing materials and solar panels, which is applied in the field of solar heat absorption, can solve the problems of low thermal efficiency of solar collectors, coatings that are not weather-resistant, and premature pulverization, etc., and achieve excellent mechanical properties, high water and temperature resistance, Good defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

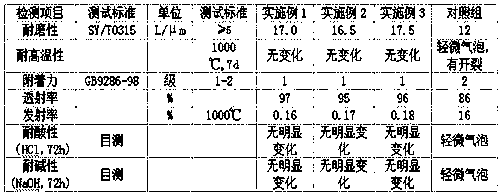

Examples

Embodiment 1

[0018] A solar panel selective heat-absorbing material and a preparation method thereof, the material is made of the following raw materials in parts by weight:

[0019] 8 parts of nano-scale spinel pigment, 6 parts of nickel powder, 40 parts of linseed oil-based water-based polyurethane-polyacrylic resin, 10 parts of drying oil alkyd resin, 6 parts of anhydrous acetone, 6 parts of EFKA3570, 8 parts of SN-5027 14 parts, polyether modified silicone oil defoamer.

[0020] The main raw materials for the synthesis of the linseed oil-based water-based polyurethane-polyacrylic acid resin are hydroxylated linseed oil, isophorone diisocyanate, polyether N210 (Mn=1000), 2,2-dimethylol propionic acid, acetal Diethylene glycol, stannous octoate, dibutyltin dilaurate, triethylamine, acetone, methyl methacrylate, butyl acrylate, sodium lauryl sulfate, potassium persulfate, and sodium bicarbonate.

[0021] The nano-scale spinel pigment is obtained by calcining the following raw materials a...

Embodiment 2

[0025] A solar panel selective heat-absorbing material and a preparation method thereof, the material is made of the following raw materials in parts by weight:

[0026] 5 parts of nano-scale spinel pigment, 4 parts of nickel powder, 30 parts of linseed oil-based water-based polyurethane-polyacrylic resin, 8 parts of drying oil alkyd resin, 4 parts of anhydrous acetone, 4 parts of EFKA3570, 4 parts of SN-5027 8 parts, polyether modified silicone oil defoamer.

[0027] The main raw materials for the synthesis of the linseed oil-based water-based polyurethane-polyacrylic acid resin are hydroxylated linseed oil, isophorone diisocyanate, polyether N210 (Mn=1000), 2,2-dimethylol propionic acid, acetal Diethylene glycol, stannous octoate, dibutyltin dilaurate, triethylamine, acetone, methyl methacrylate, butyl acrylate, sodium lauryl sulfate, potassium persulfate, and sodium bicarbonate.

[0028] The nano-scale spinel pigment is obtained by calcining the following raw materials aft...

Embodiment 3

[0032] A solar panel selective heat-absorbing material and a preparation method thereof, the material is made of the following raw materials in parts by weight:

[0033] 10 parts of nano-scale spinel pigment, 8 parts of nickel powder, 50 parts of linseed oil-based water-based polyurethane-polyacrylic resin, 12 parts of drying oil alkyd resin, 8 parts of anhydrous acetone, 8 parts of EFKA3570, 12 parts of SN-5027 part, 20 parts of polyether modified silicone oil defoamer.

[0034] The main raw materials for the synthesis of the linseed oil-based water-based polyurethane-polyacrylic acid resin are hydroxylated linseed oil, isophorone diisocyanate, polyether N210 (Mn=1000), 2,2-dimethylol propionic acid, acetal Diethylene glycol, stannous octoate, dibutyltin dilaurate, triethylamine, acetone, methyl methacrylate, butyl acrylate, sodium lauryl sulfate, potassium persulfate, and sodium bicarbonate.

[0035] The nano-scale spinel pigment is obtained by calcining the following raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com