A laser additive manufacturing or remanufacturing conformal protection method and protective cover

A technology of laser additive and protective cover, applied in the field of protective cover, laser additive manufacturing or remanufacturing conformal protection, can solve the problem of not being able to meet large workpieces, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

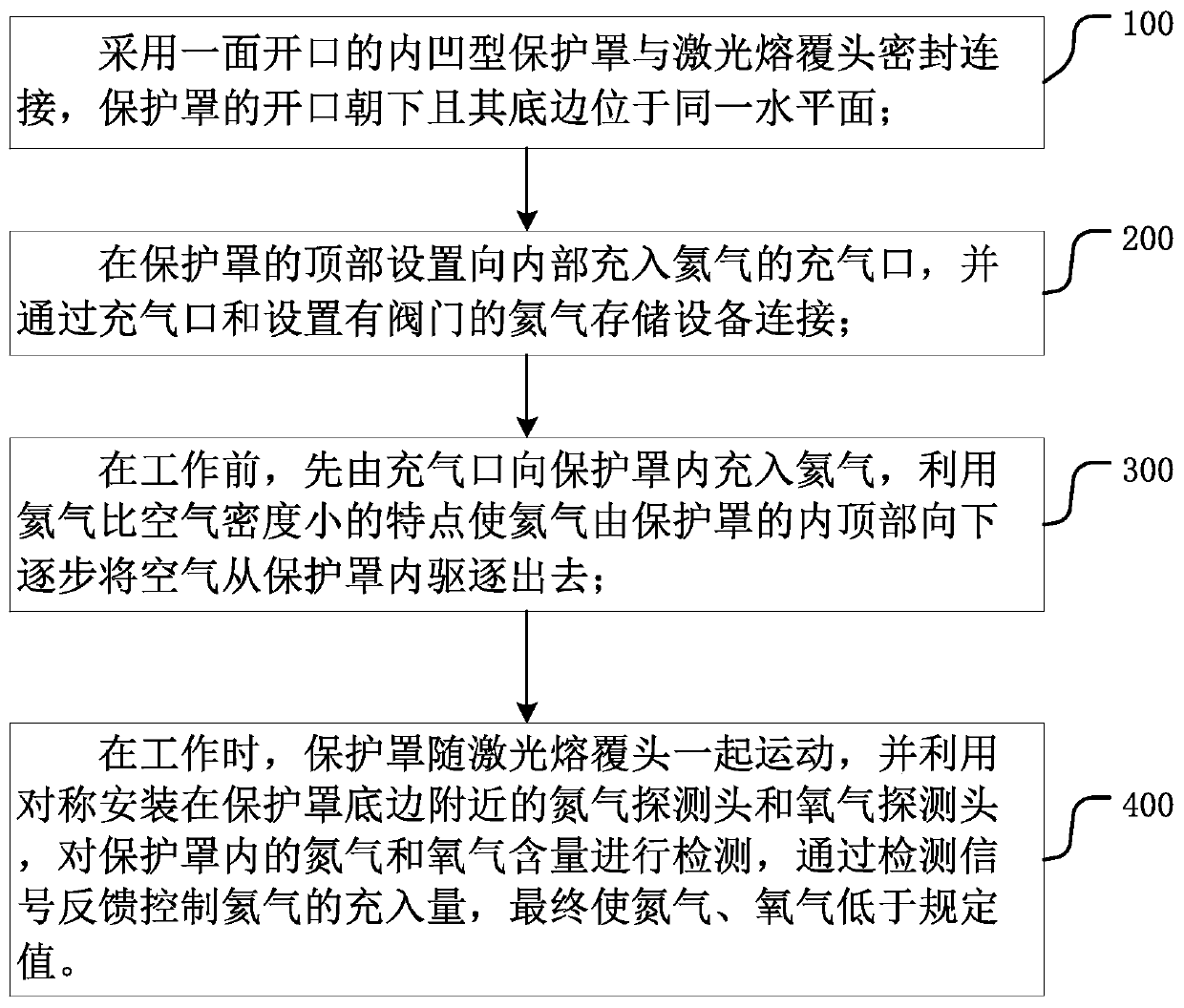

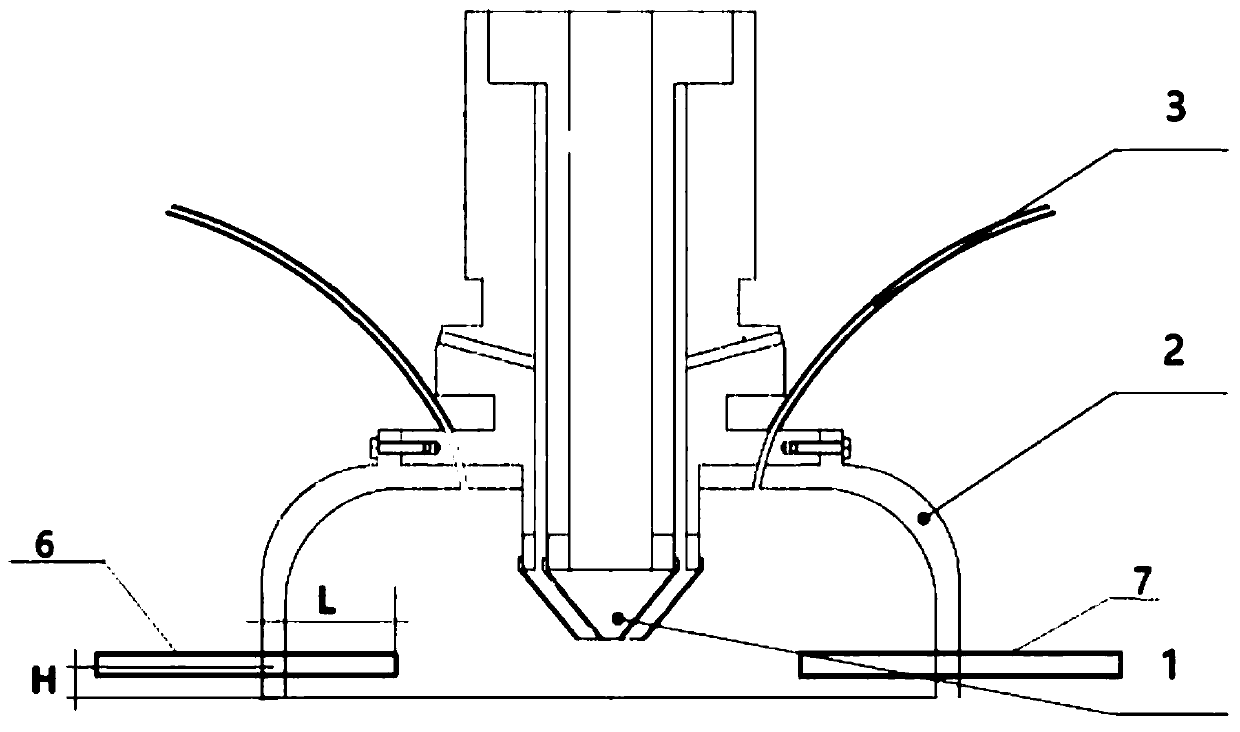

[0049] The shape of the protective cover 2 is cylindrical, with an outline of Φ700×400mm. The side and top surfaces are made of stainless steel sheets with a thickness of 0.2mm. There is an interface on the top of the cover, which can be connected to the general laser cladding head 1;

[0050] Inflate helium into the hood through the inflation tube near the top of the hood. Since helium is lower in density than air, the helium in the hood gradually expels the air and squeezes the air out from the bottom of the protective cover 2, and measures it with the probe in the protective cover 2. Oxygen and nitrogen content, so that the oxygen content is ≤100ppm, and the nitrogen content is ≤100ppm;

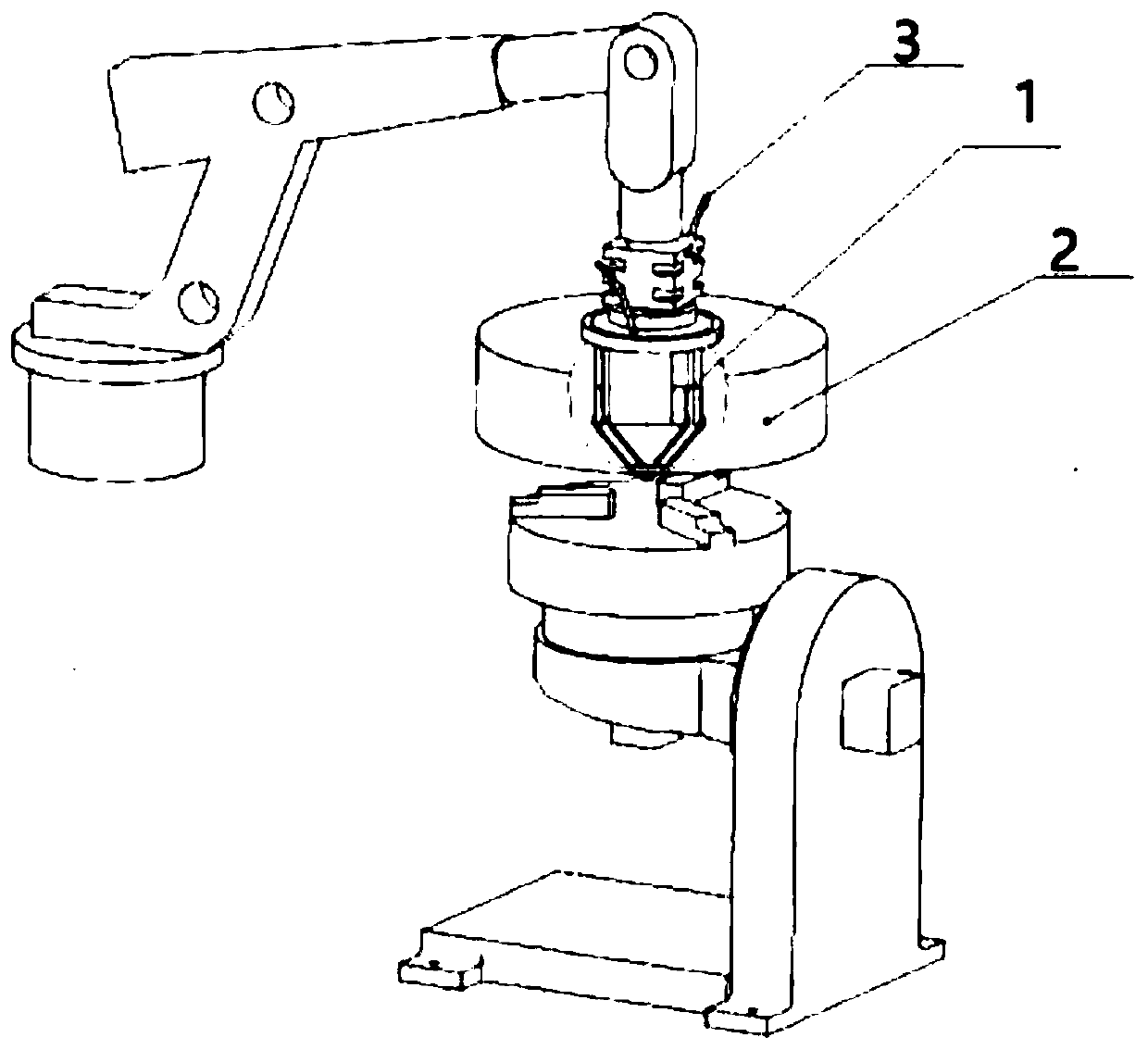

[0051] The workpiece manufactured by laser additive manufacturing will be stacked and formed on a 200mm×200mm×20mm steel plate, and the steel plate is fixed horizontally on a positioner that can tilt from -90° to +90° and rotate 360°. The working platform of the positioner The volume is le...

Embodiment 2

[0054] The shape of the protective cover 2 is bell-shaped, the bottom side is 300mm×300mm square, and the height is 200mm. The cover surface is made of flame-retardant cloth, and there is an interface on the top of the cover, which can be connected with a general laser cladding head;

[0055] Inflate helium into the hood through the inflation tube near the top of the hood. Since helium is lower in density than air, the helium in the hood gradually expels the air and squeezes the air out from the bottom of the protective cover 2, and measures it with the probe in the protective cover 2. Oxygen and nitrogen content, so that the oxygen content is ≤100ppm, and the nitrogen content is ≤100ppm;

[0056] The workpiece that needs to be remanufactured by laser is a shaft of Φ400×2000mm. The center line of the shaft is horizontal, and the two ends are fixed on the positioner and the support seat that can rotate 360°. Fasten the protective cover 2 on the side of the shaft to be processed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com