A vacuum continuous melting and casting device for copper alloy

A technology of vacuum smelting and vacuum casting, which is applied in the field of copper alloy casting, which can solve the problems of unclean metal casting, influence of casting process, inconvenient casting process, etc., achieve sufficient and uniform alloy composition, ensure stable casting process, and facilitate the replacement of alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

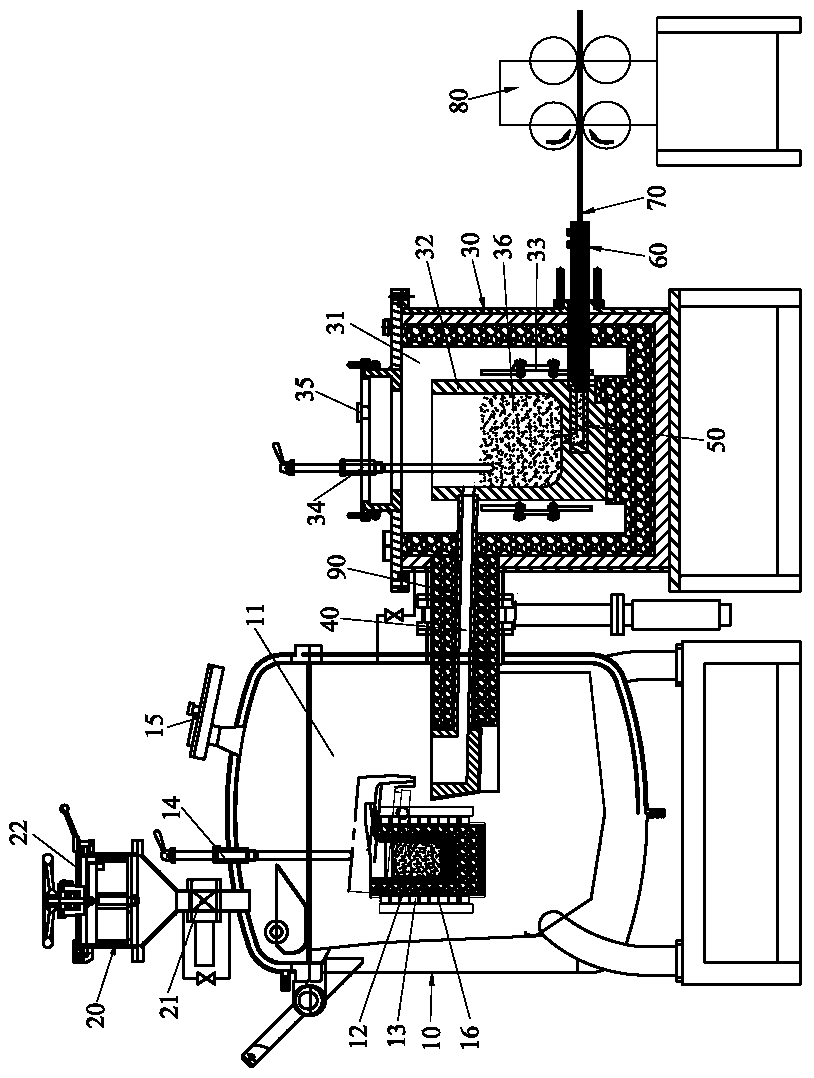

[0071] In this embodiment, a copper alloy vacuum continuous melting and casting device is composed of a vacuum melting chamber 10, a continuous vacuum feeding chamber 20, a vacuum casting chamber 30, an upper launder 40, a lower launder 50, a crystallizer 60, a dummy head 70, and a tractor 80. composition. The device is used to prepare chromium-zirconium bronze with a chromium content of 0.7wt%, a zirconium content of 0.2wt%, and an ingot diameter of Φ30mm.

[0072] The melting crucible 12 in the vacuum melting chamber 10 has a volume of 150 kg, the casting crucible 32 in the vacuum casting chamber 30 has a volume of 150 kg, the heating element 33 is a silicon carbide rod, and the inclination angle of the upper launder 40 is 10°. The melting and casting method includes the following steps:

[0073] (1) Assemble the above-mentioned copper alloy vacuum continuous melting and casting device, the melting thermocouple 14 and the casting thermocouple 34 are moved up to a position c...

Embodiment 2

[0086] In this embodiment, a copper alloy vacuum continuous melting and casting device is composed of a vacuum melting chamber 10, a continuous vacuum feeding chamber 20, a vacuum casting chamber 30, an upper launder 40, a lower launder 50, a crystallizer 60, a dummy head 70, and a tractor 80. composition. The device is used to prepare a B30 white copper tube billet with a nickel content of 30wt%, an ingot outer diameter of Φ20mm, and a wall thickness of 4mm.

[0087] The melting crucible 12 in the vacuum melting chamber 10 has a volume of 50 kilograms, the casting crucible 32 in the vacuum casting chamber 30 has a volume of 50 kilograms, the heating element 33 is a silicon carbide rod, and the inclination angle of the upper launder 40 is 10°. The melting and casting method includes the following steps:

[0088] (1) Assemble the above-mentioned copper alloy vacuum continuous melting and casting device, the melting thermocouple 14 and the casting thermocouple 34 are moved up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com