Preserved sweet potato immersing liquid and preparation method thereof

A technology for dipping liquid and sweet potato, which is applied to the dipping solution of preserved sweet potato and the field of preparation thereof, can solve the problems of poor preparation process, low nutritional value, dry and hard preserved sweet potato, etc., and achieves improvement of nutritional value, health-care efficacy, and fiber content. sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

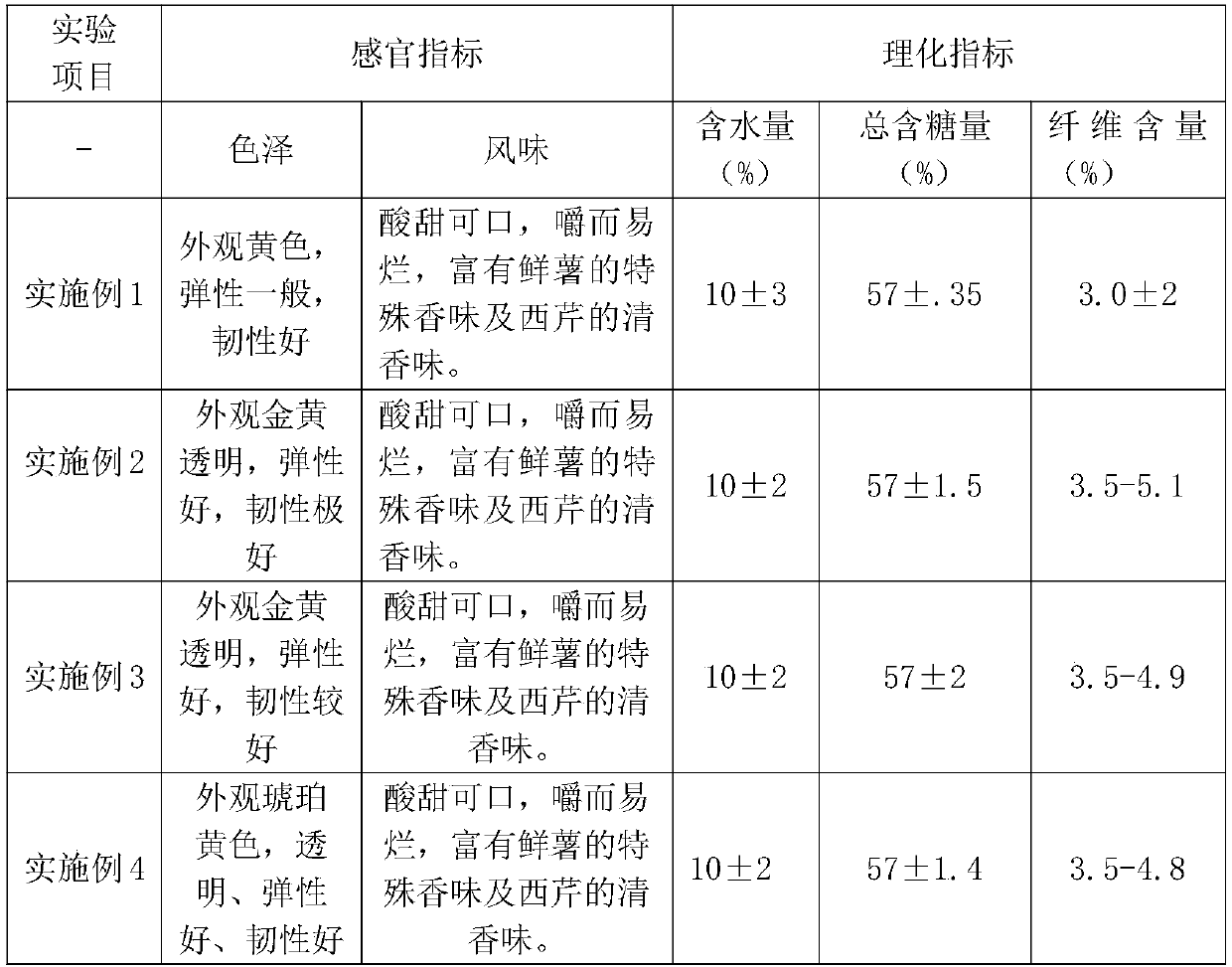

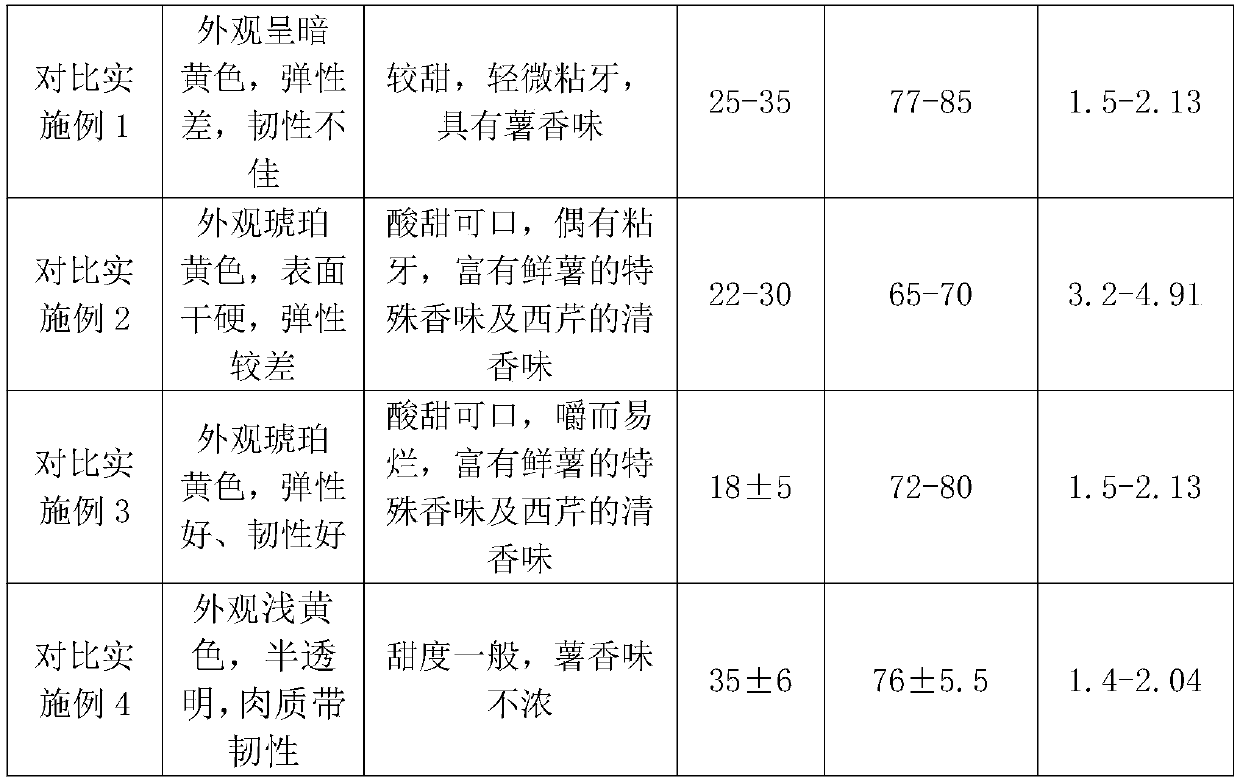

Examples

Embodiment 1

[0028] S1: Raw material processing: select fresh sweet potatoes with tight texture, no trauma, no pollution and no decay, divide them into small potatoes and large potatoes, wash them, remove insect eyes, black spots, and peel them, and cut the large potatoes into lengths of 10-14cm and width 1-2cm strips, then soak the peeled small potatoes and strips in water for later use;

[0029] S2: Steaming and semi-drying of raw materials: use celery juice to steam steam the spare small potatoes and strip potatoes in step S1; after steaming, remove the well-ripe sweet potatoes and place them at a temperature of 60-80°C drying in an environment until the moisture content is 62%-70%, and then cooling to 25-30°C to prepare semi-dried cooked sweet potatoes for later use;

[0030] S3: Sugar cooking and dipping: Boil the semi-dried sweet potatoes in step S2 in the first sugar solution--soak in the first dipping solution--boil in the second sugar solution--soak in the second dipping solution-...

Embodiment 2

[0044] S1: Raw material processing: select fresh sweet potatoes with tight texture, no trauma, no pollution and no decay, divide them into small potatoes and large potatoes, wash them, remove insect eyes, black spots, and peel them, and cut the large potatoes into lengths of 10-14cm and width 1-2cm strips, then soak the peeled small potatoes and strips in water for later use;

[0045] S2: Steaming and semi-drying of raw materials: use celery juice to steam the spare small potatoes and strips of potatoes in step S1; after steaming, remove the well-ripe sweet potatoes and place them in an environment with a temperature of 60°C drying in medium temperature until the moisture content is 62%, and then cooling to 25°C to prepare semi-dried cooked sweet potatoes for later use;

[0046] S3: Sugar cooking and dipping: Boil the semi-dried sweet potatoes in step S2 in the first sugar solution--soak in the first dipping solution--boil in the second sugar solution--soak in the second dippi...

Embodiment 3

[0060] S1: Raw material processing: select fresh sweet potatoes with tight texture, no trauma, no pollution and no decay, divide them into small potatoes and large potatoes, wash them, remove insect eyes, black spots, and peel them, and cut the large potatoes into lengths of 10-14cm and width 1-2cm strips, then soak the peeled small potatoes and strips in water for later use;

[0061] S2: Steaming and semi-drying of raw materials: use celery juice to steam the spare small potatoes and strips of potatoes in step S1; after steaming, remove the well-ripe sweet potatoes and place them in an environment with a temperature of 70°C drying in a medium temperature until the moisture content is 65%, and then cooling to 27°C to prepare half-dried cooked sweet potatoes for later use;

[0062] S3: Sugar cooking and dipping: Boil the semi-dried sweet potatoes in step S2 in the first sugar solution--soak in the first dipping solution--boil in the second sugar solution--soak in the second dip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com