A full-length thermal insulation pipe with inner pipe direct connection

A thermal insulation and direct connection technology, applied in the direction of drilling pipe, casing, wellbore/well components, etc., can solve the problems of small heat conduction resistance, unsafety, heat loss reduction, etc., to save energy and improve heat preservation Effect, the effect of improving steam injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

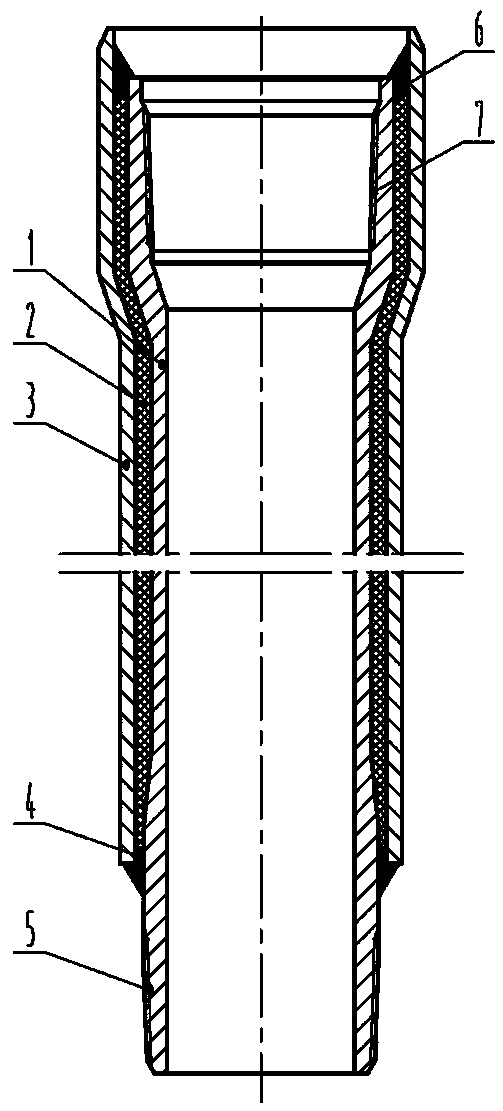

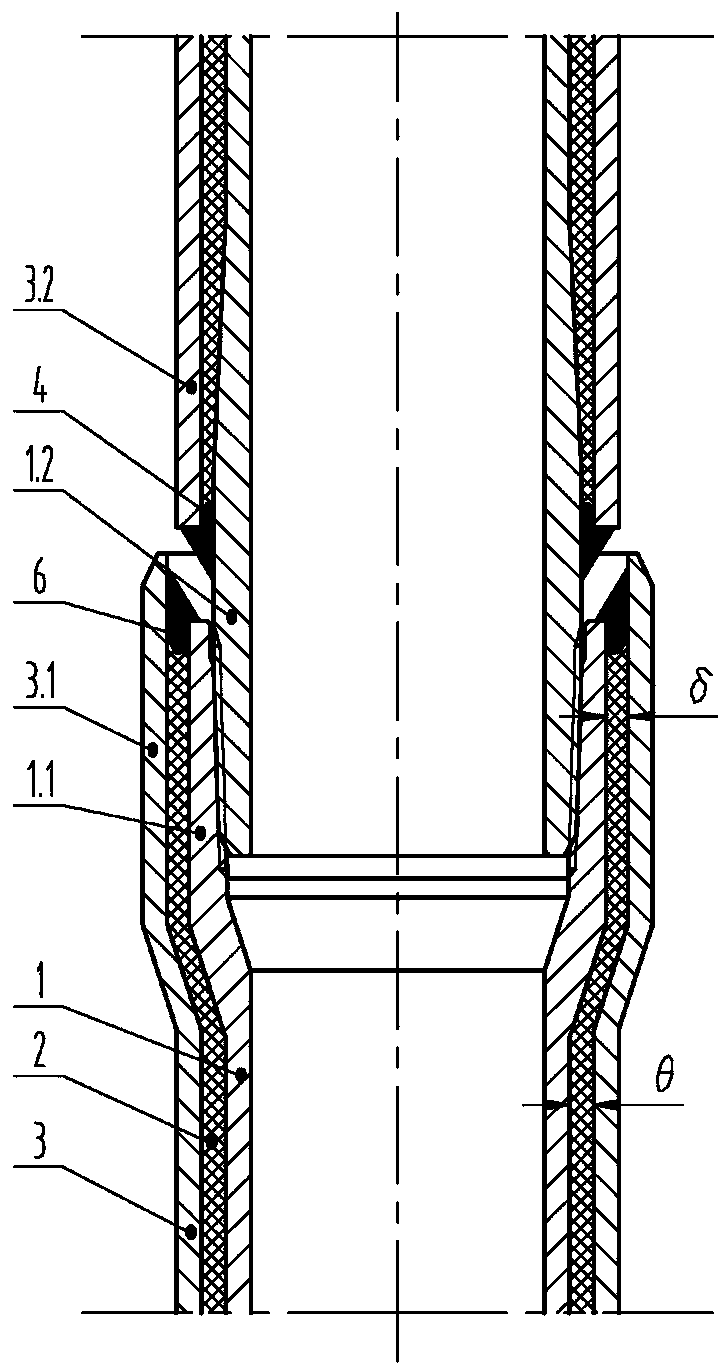

[0008] The present invention is described in detail below in conjunction with accompanying drawing: it comprises inner pipe 1, insulation layer 2, outer pipe 3, inner thread 7, outer thread 5, and one end of inner pipe 1 processes inner thread 7, and the other end processes outer thread 5, inner The inner pipe 1.1 at the threaded end is directly connected to the inner pipe 1.2 at the outer threaded end of another heat-insulating pipe; The diameter is 10-16mm larger than the thickened outer diameter of the 1.2 end of the inner tube at the external thread end, and the outer diameter of the 3.1 end of the outer tube at the inner thread end is flared, and the gap between the inner diameter of the flared part and the outer diameter of the 1.1 thickened end of the inner tube at the female thread end is δ , the thickness of the thermal insulation layer between the inner tube 1 and the outer tube 3 is θ, and its δ≈θ, and the thermal insulation layer is also wrapped in the annular space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com