Assembly-type composite tube sea-water sea-sand concrete bridge pier and manufacturing method

A composite pipe and concrete technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of large floor area, poor structural durability, easy buckling of steel pipes, etc., and achieve high bearing capacity, good durability, and environmental protection The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following specific examples.

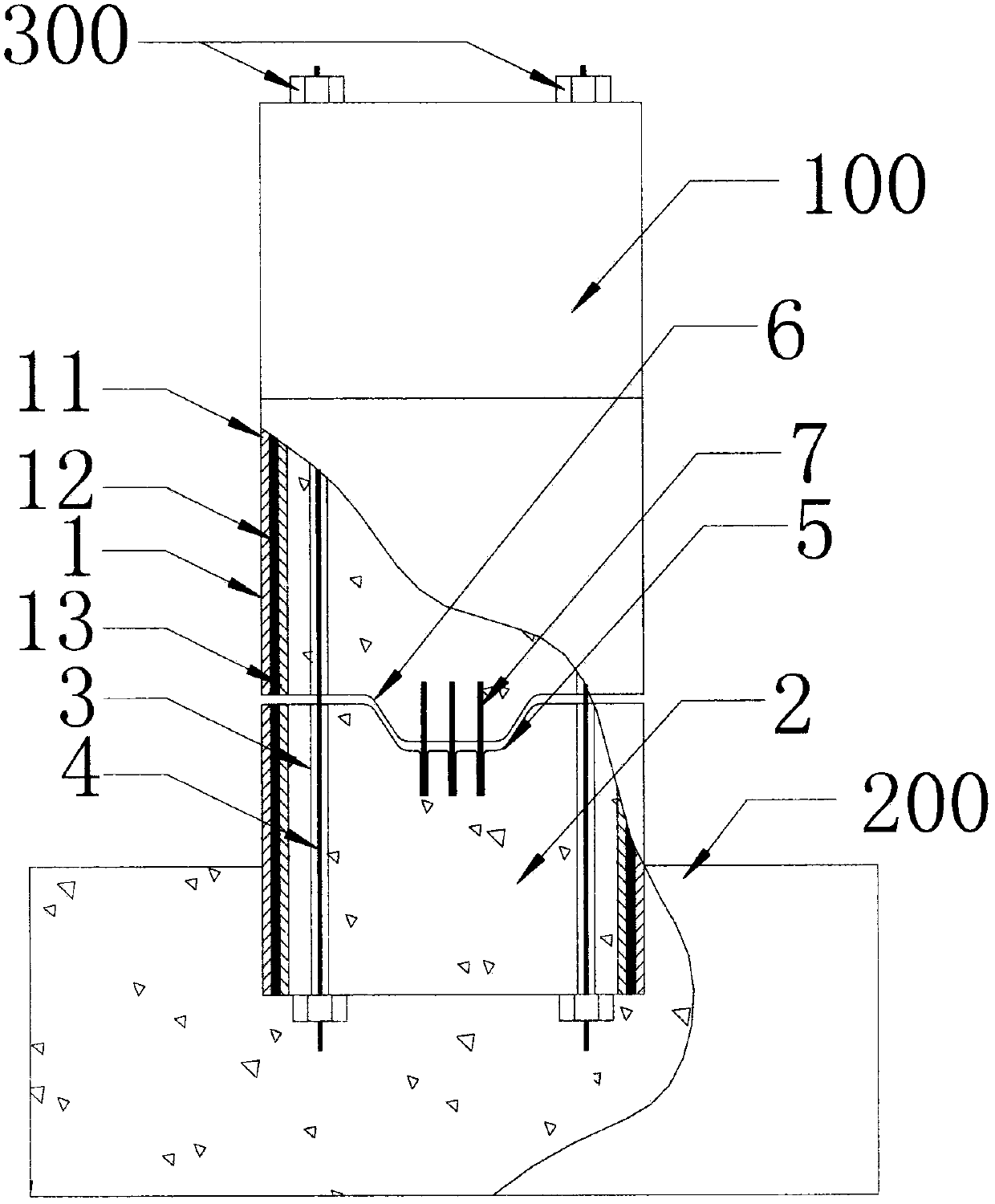

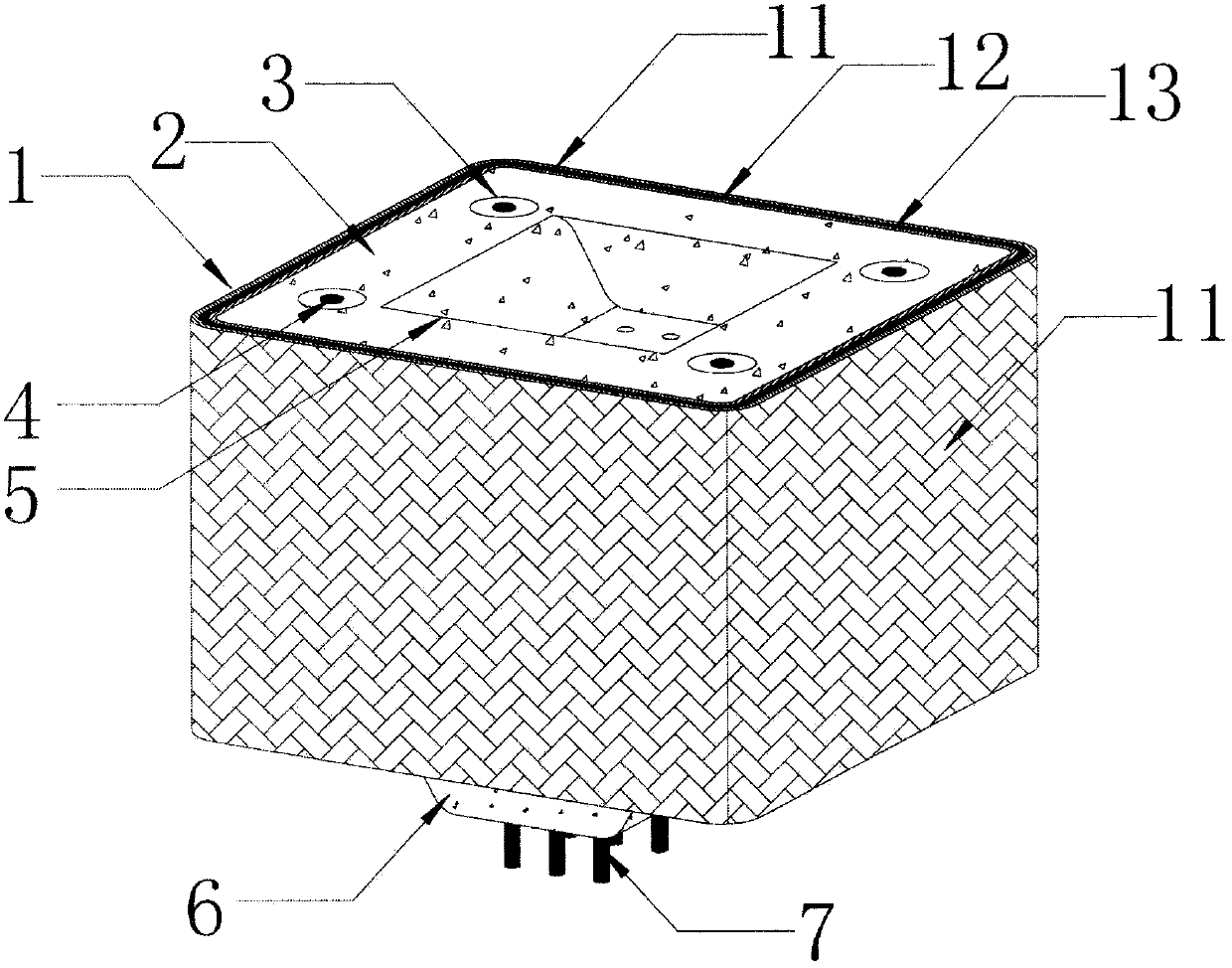

[0043] An assembled compound pipe seawater sea sand concrete bridge pier, the structure is composed of a plurality of superimposed composite pipe seawater sea sand concrete column segments 100, which are connected as a whole through post-tensioning prestressing, which is characterized in that the Composite pipe seawater sea sand concrete pier column segment 100 is composed of composite pipe 1, seawater sea sand concrete 2, corrugated pipe 3, prestressed reinforcement 4, and shear reinforcement 7. Composite pipe 1 is composed of inner fiber layer 13, outer fiber layer 11 are respectively bonded to the inner wall and outer wall of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com