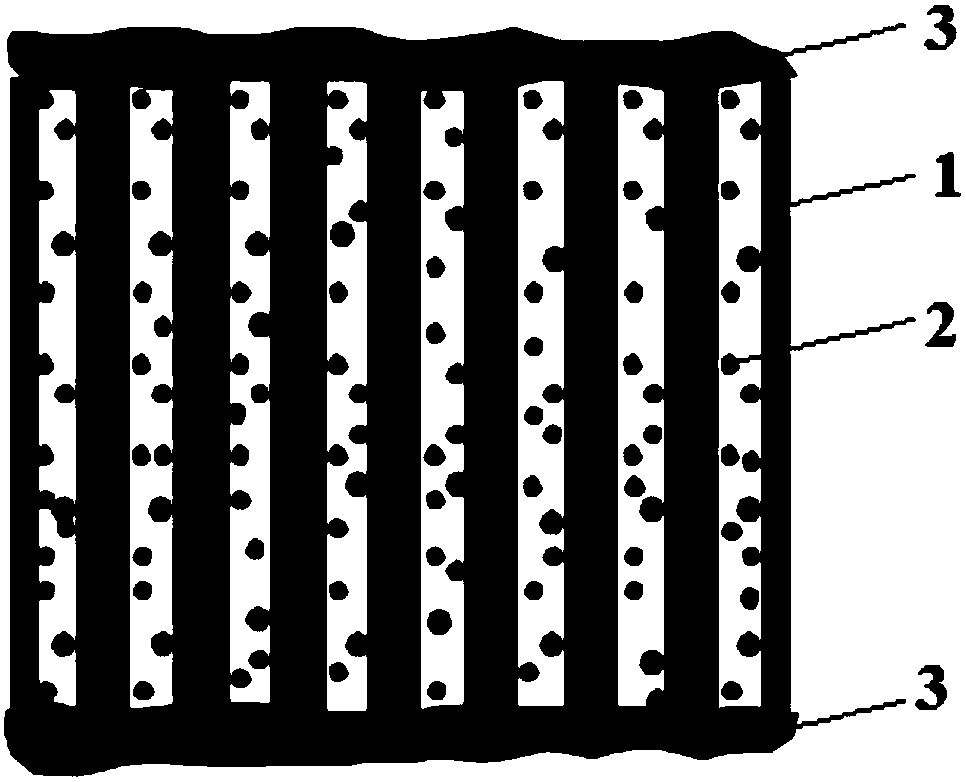

Orderly-arranged silicon-filled carbon nanotube material and preparation method and use thereof

A technology of carbon nanotubes and orderly arrangement, which is applied in the field of silicon-filled carbon nanotube materials and preparation, and can solve the problems of battery cycle performance degradation, separation of electrode active materials and current collectors, and structural collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

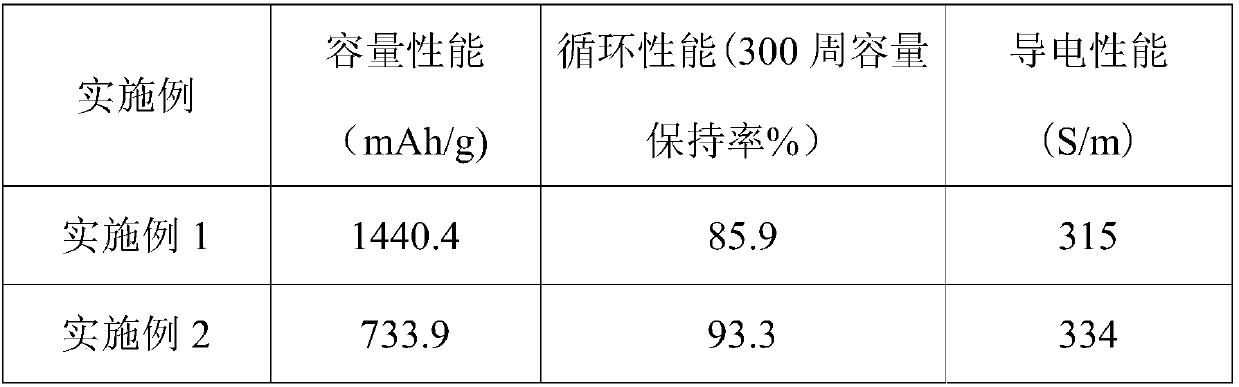

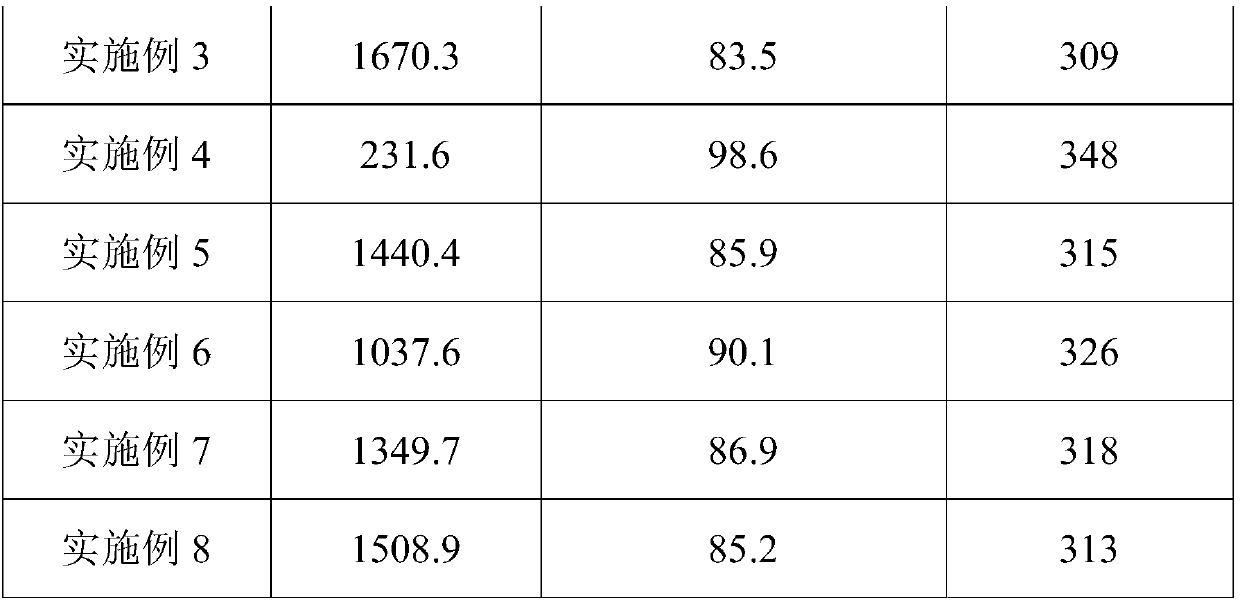

Embodiment 1

[0049] Immerse 100 g of anodized aluminum template with holes at both ends in 150 mL of a cyclohexane solution of polypyrrole with a mass fraction of 0.02 g / mL for 1 h, filter, and then wash the filter residue with cyclohexane solvent and ethanol, and bake at 50 °C. After drying for 10 hours, the dried anodized alumina template was placed in a high-temperature furnace in an argon atmosphere, and kept at 800° C. for 2 hours to obtain ordered carbon nanotubes with alumina template. Dissolve 21 g of silicon tetrachloride in 100 mL of anhydrous ethane, add the ordered carbon nanotubes with alumina template into the anhydrous ethane solution of silicon tetrachloride, soak for 2 h, and then use anhydrous ethane, Ethanol was used to clean the residual silicon tetrachloride on the surface of the alumina template, and then 4.7 g of sodium borohydride was slowly added dropwise from one end of the ordered carbon nanotubes, so that the sodium borohydride solution gradually penetrated throu...

Embodiment 2

[0051] 100 g of anodized aluminum template with openings at both ends was immersed in 150 mL of a polyacrylonitrile n-octane solution with a mass fraction of 0.05 g / mL for 0.5 h, filtered, and then the filter residue was washed with cyclohexane solvent and ethanol. After drying at ℃ for 2 h, the dried anodized alumina template was placed in a high-temperature furnace with nitrogen atmosphere, and kept at 700 ℃ for 3 h to obtain ordered carbon nanotubes with alumina template. Dissolve 10.5 g of silicon tetrachloride in 100 mL of anhydrous ethane, and add the ordered carbon nanotubes with alumina template into the anhydrous ethane solution of silicon tetrachloride, soak for 4 h, and then use anhydrous ethane , ethanol to clean the residual silicon tetrachloride on the surface of the alumina template, and then slowly drop 2.0 g of hydrazine hydrate from one end of the ordered carbon nanotubes, so that the hydrazine hydrate solution gradually penetrates through the carbon nanotube ...

Embodiment 3

[0053] 100 g of anodized aluminum template with openings at both ends was immersed in 150 mL of a cyclohexane solution of polystyrene with a mass fraction of 0.1 g / mL for 2 h, filtered, and then the filter residue was washed with cyclohexane solvent and ethanol, at 70 °C After drying for 8 hours, the dried anodized alumina template was placed in a high-temperature furnace in an argon atmosphere, and kept at 750° C. for 4 hours to obtain ordered carbon nanotubes with alumina template. Dissolve 210 g of silicon tetrachloride in 100 mL of anhydrous ethane, add the ordered carbon nanotubes with alumina template into the anhydrous ethane solution of silicon tetrachloride, soak for 6 h, and then use anhydrous ethane, Ethanol was used to clean the residual silicon tetrachloride on the surface of the alumina template, and then 42.5g of hydrogen peroxide was slowly added dropwise from one end of the ordered carbon nanotubes, so that the hydrogen peroxide solution gradually penetrated th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com