Combined type locking washer

A locking washer, combined technology, applied in the direction of washers, locking fasteners, threaded fasteners, etc., can solve the problems of damaged threads on the surface of the screw, easy to be crushed, frequent use, etc., to prevent Sliding phenomenon, the effect of preventing up and down vibration and lateral translation, and improving its own strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

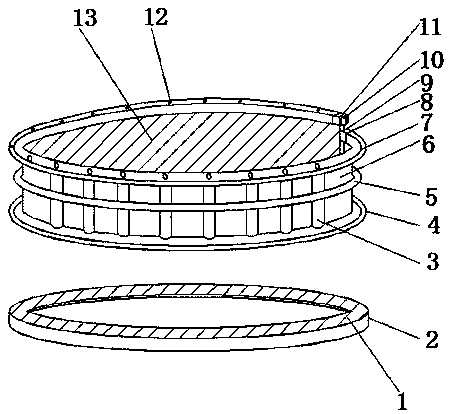

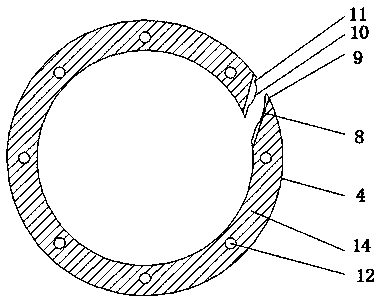

[0016] refer to figure 1 and figure 2 , a combined locking washer, including a clamping washer 2 and a support ring 6 fixed on the outer wall of the screw rod, the outer wall of the top of the clamping washer 2 is provided with a first locking pattern 1, and the outer wall of the top of the support ring 6 is welded with an upper gasket 7. The outer wall of the bottom of the support ring 6 is welded with the lower gasket 4, the outer wall of the bottom of the lower gasket 4 is provided with a second card pattern 14, and the outer wall of the top of the upper gasket 7 and the outer wall of the bottom of the lower gasket 4 are welded with bumps 12, The inner wall of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com