Equipment wire clamp anti-breaking device

An equipment clamp and anti-break technology, which is applied to the coupling device, the device for reducing the stress at the connection point of the wire, and the parts of the connection device, etc., can solve the problem of corrosion, burnout of the equipment clamp, and unstable operation of the 10kV power distribution network. problem, achieve the effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

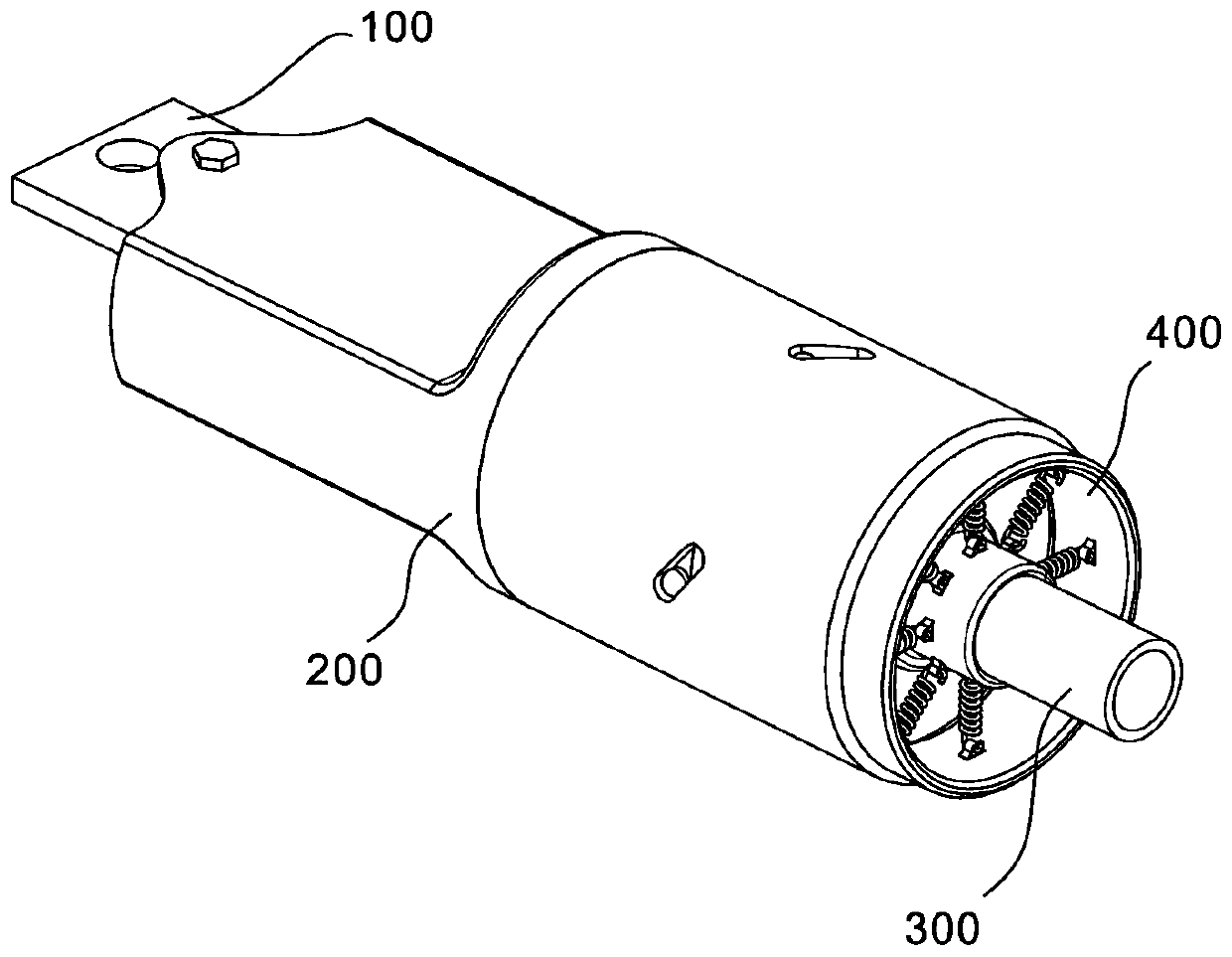

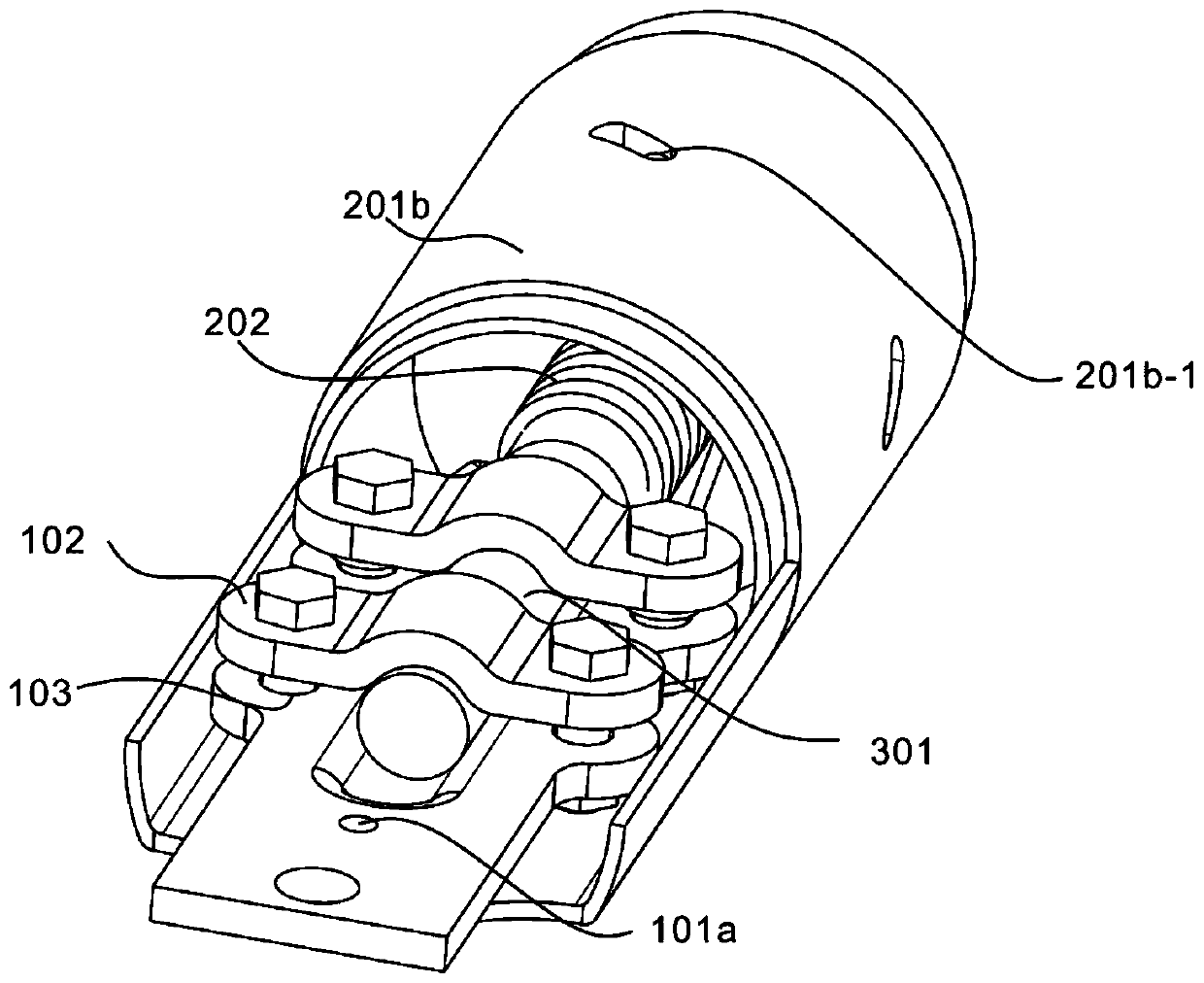

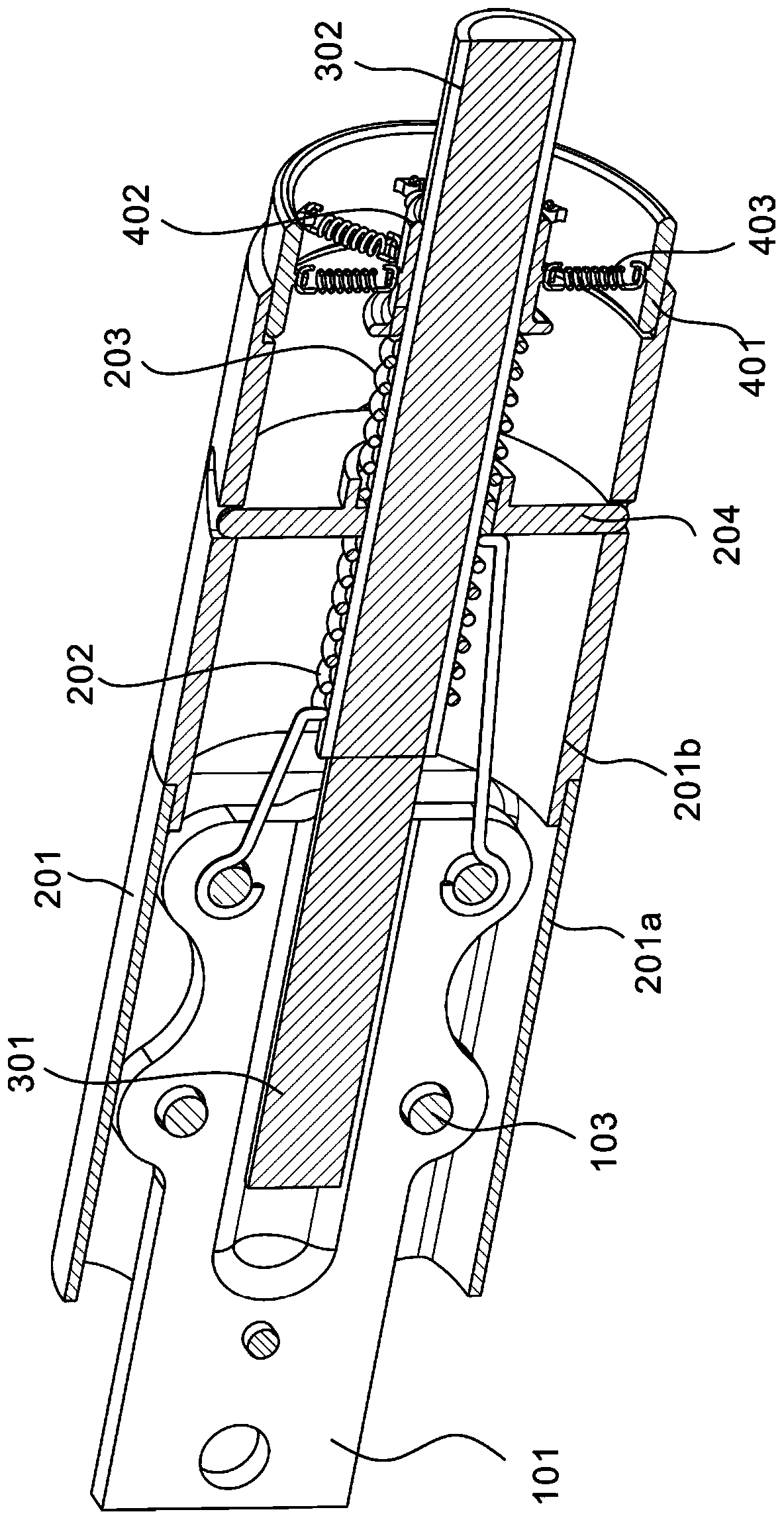

[0032] refer to Figure 1-7 , the present embodiment provides an equipment line clip anti-breakage device, including an equipment line clamp 100, including an outgoing line terminal 101, a clamping piece 102 connected to the outgoing line terminal 101, and a bolt 103, and the bolt 103 fastens the clamping piece 102 to the On the outgoing line terminal 101, the outgoing line terminal 101 is a conductor, which is drawn out from the power equipment and connected with the external wire. The clamping piece 102 is used to fasten the lead on the outgoing line terminal 101 and fastened by the bolt 103 to prevent falling off; anti-breakage The unit 200 includes a box body 201 sleeved on the equipment clamp 100, a first spring 202 and a second spring 203 connected to the bolt 103, a spring seat 204 is arranged between the first spring 202 and the second spring 203, and the spring The seat 204 is located in the box body 201. The winding direction of the first spring 202 and the second sp...

Embodiment 2

[0041] refer to Figure 1-7 , is the second embodiment of the present invention, this embodiment is based on the previous embodiment, and the difference from the previous embodiment is: the outlet terminal 101 is provided with a fixing hole 101a, and one end of the first box body 201a is provided with a positioning end 201a -1, the positioning end 201a-1 is connected to the fixing hole 101a through the fixing bolt 205 .

[0042] Specifically, the equipment clamp 100 includes an outgoing line terminal 101, a clamping piece 102 connected to the outgoing line terminal 101, and a bolt 103. The bolt 103 fastens the clamping piece 102 to the outgoing line terminal 101. The outgoing line terminal 101 is a conductor, and the The equipment lead is connected with the external wire, and the clamping piece 102 is used to fasten the wire on the outlet terminal 101 and fasten it through the bolt 103 to prevent it from falling off; The box body 201, the first spring 202 and the second sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com