Vertical double-end-face grinding wheel dresser

A grinding wheel dressing, double-end face technology is applied in abrasive surface adjustment devices, machine tools suitable for grinding workpiece planes, grinders, etc. Smooth movement, improved grinding quality, flat surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

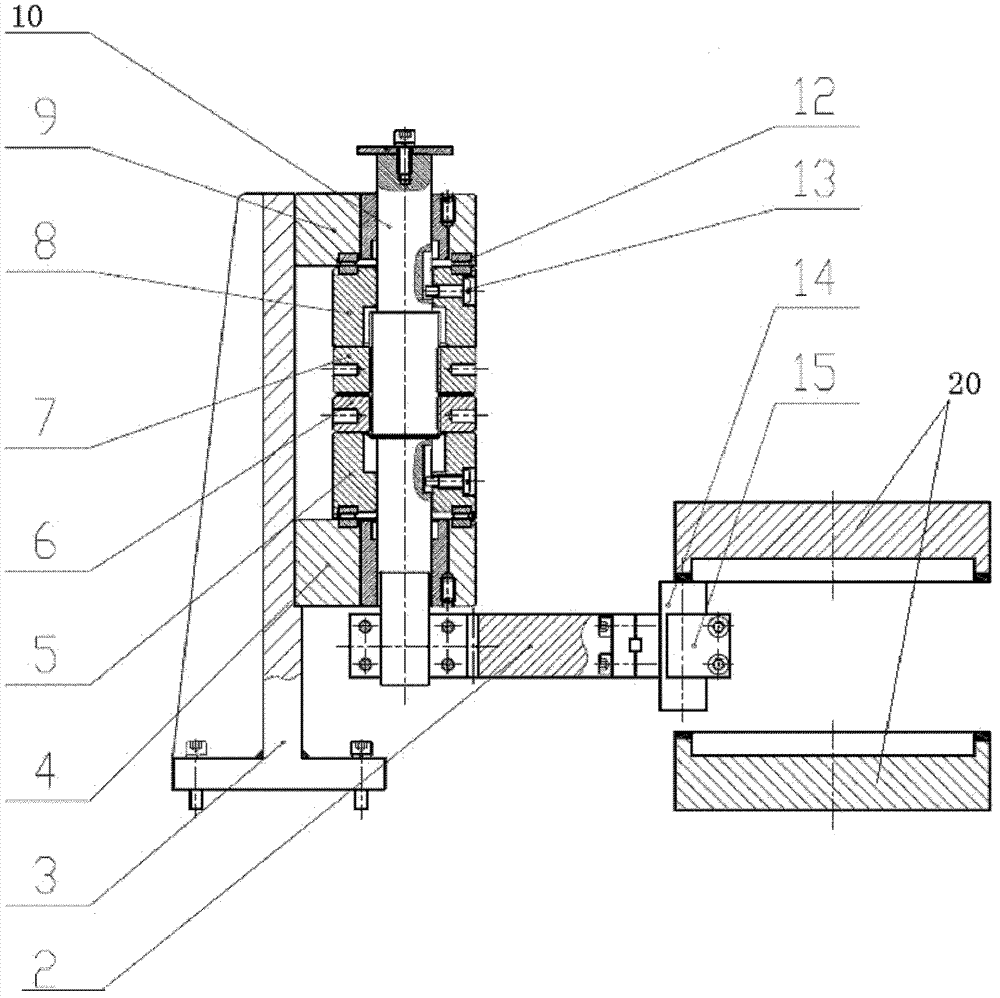

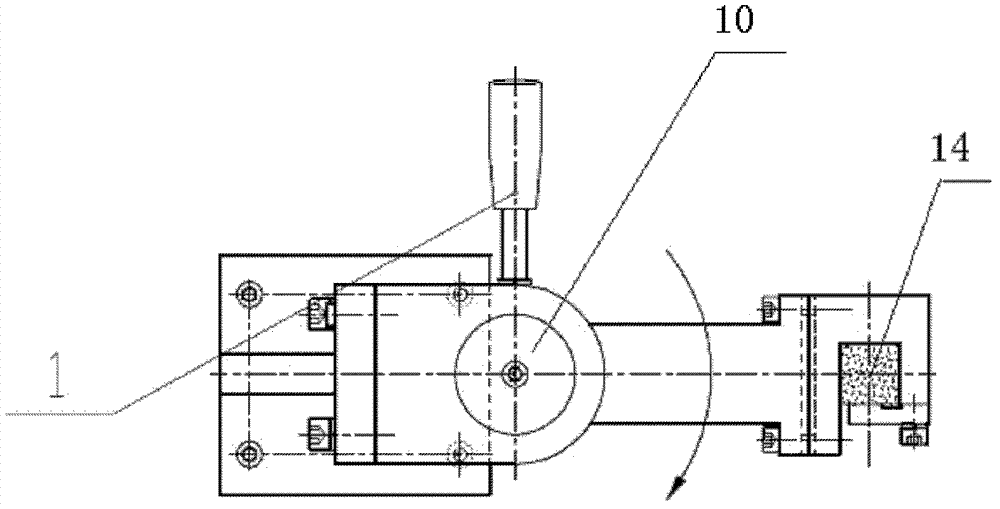

[0010] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 , figure 2 As shown, the present invention comprises support 3, handle 1, and described support 3 is fixed on the grinder, and the upper and lower ends of described support 3 are respectively fixed with upper bearing seat 9 and lower bearing seat 4 by bolts, and described upper bearing seat 9 Bearings are arranged in the lower bearing seat 4, and a rotating shaft 10 is arranged between the bearings. The middle part of the rotating shaft 10 is provided with threads, and a linkage sleeve 8, an upper adjusting nut 7, and a lower adjusting nut are sequentially arranged between the upper and lower ends of the support. Nut 6, pad cover 5; described upper adjustment nut 7, lower adjustment nut 6 are matched with the thread provided in the middle part of the rotating shaft 10; the linkage sleeve 8 and the pad cover 5 are fixed with the circumference of the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com