Self-compensating, locking and quick-connecting high-pressure pipe connector

A self-compensating, high-pressure pipe technology, applied to pipes/pipe joints/fittings, expansion compensation devices for pipelines, pipe components, etc., can solve problems such as unfavorable energy saving and emission reduction, poor practicability, and increased manufacturing costs, and achieve shortening The installation period, the sealing effect is good, and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

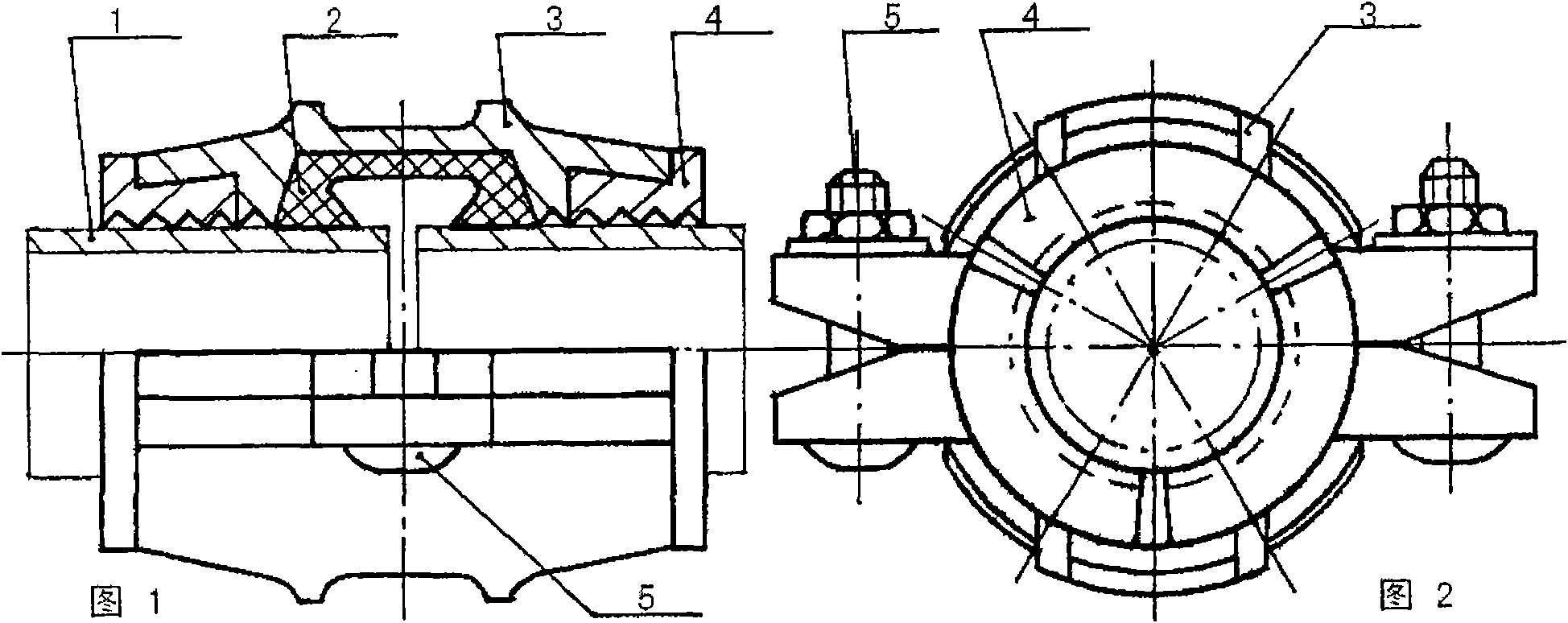

[0038] The present invention is described in further detail below in conjunction with accompanying drawing and embodiment thereof:

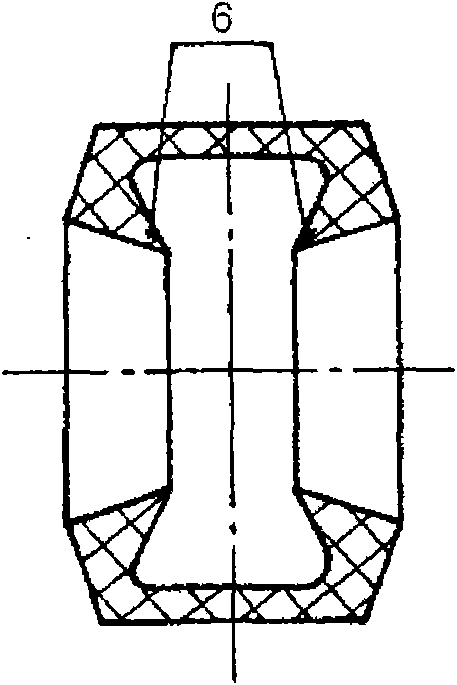

[0039] figure 1 , 2 The overall structure of the self-compensating lockable quick-connect high-pressure pipe joint of the present invention is shown. It is characterized in that the rubber sealing sleeve 2 surrounds the outer circle of the pipe fitting 1, the rubber sealing sleeve 2 is provided with an angle ring 6 with an open inner cavity, and is placed on the outer wall of the nozzle of the two pipe fittings, and the trapezoidal boss provided on the clamp 3 8 is coordinated with the trapezoidal groove 9 provided on the clamp 3 and fastened symmetrically on the pipe fitting 1, and pressed against the outer surface of the rubber sealing sleeve 2. The inner circular surface of the clamp 3 is provided with a circular tine 10 and They are respectively pasted on the outer walls of the pipe fittings 1 with the same arc. Three groups of claws 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com