A kind of preparation method of long-fiber carbon ceramic fastener

A technology for fasteners and carbon ceramics, applied in the field of preparation of long-fiber carbon ceramics fasteners, can solve the problems of low gas source conversion rate, low thermal expansion coefficient, small friction coefficient, etc., to improve deposition rate and gas source utilization The effect of high rate and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of a long-fiber carbon ceramic fastener, comprising the steps of:

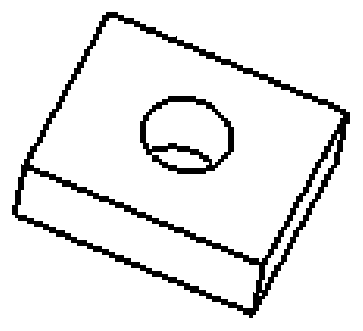

[0040] (1) A layer of long fiber non-weft cloth (length * width is 400*400mm, long fiber length is 400mm, fineness is 0.6mm), and a layer of short fiber mesh tire (length * width is 400*400mm, short The fiber length is 65mm and the fineness is 0.6mm), and the layers are alternately laid. The angle between the fiber directions between the adjacent long fiber non-weft fabric layers is 90°. Thickness up to 30mm. Needling density is 20 needles / cm 2 , the interlayer density is 16 layers / cm, the mass content of long fiber non-weft fabric is 85%, the mass content of short fiber mesh is 15%, and the final weaving is 0.5g / cm 3 Three-dimensional acupuncture preforms, which are finally cut into figure 1 As shown, a three-dimensional needle punched preform with a through hole in the center, the diameter of the through hole being about φ50 mm.

[0041] (2) placing the three-dimensional acupu...

Embodiment 2

[0045] A preparation method of a long-fiber carbon ceramic fastener, comprising the steps of:

[0046] (1) A layer of long fiber non-weft cloth (length * width is 400*400mm, long fiber length is 400mm, fineness is 0.6mm), and a layer of short fiber mesh tire (length * width is 400*400mm, short The fiber length is 65mm and the fineness is 0.6mm), and the layers are alternately laid. The angle between the fiber directions between the adjacent long fiber non-weft fabric layers is 90°. Thickness up to 30mm. Needling density is 25 needles / cm 2 , the interlayer density is 18 layers / cm, the mass content of long fiber non-weft fabric is 75%, the mass content of short fiber mesh is 25%, and the final weaving is 0.6g / cm 3 Three-dimensional acupuncture preforms, which are finally cut into figure 1 As shown, the center is a three-dimensional acupuncture preform with a through hole, and the diameter of the through hole is about φ50mm;

[0047] (2) placing the three-dimensional acupunct...

Embodiment 3

[0051] A preparation method of a long-fiber carbon ceramic fastener, comprising the steps of:

[0052] (1) A layer of long fiber non-weft cloth (length * width is 400*400mm, long fiber length is 400mm, fineness is 0.6mm), and a layer of short fiber mesh tire (length * width is 400*400mm, short The fiber length is 60mm, the fineness is 0.6mm), and the layers are alternately laid, and the angle between the fiber directions between the adjacent long fiber non-weft fabric layers is 90°. Thickness up to 30mm. Needling density is 23 needles / cm 2 , the interlayer density is 17 layers / cm, the mass content of the long fiber non-weft fabric is 80%, the mass content of the short fiber mesh is 20%, and the final weaving is the bulk density of 0.55g / cm 3 Three-dimensional acupuncture preforms, which are finally cut into figure 1 As shown, the center is a three-dimensional acupuncture preform with a through hole, and the diameter of the through hole is φ50mm;

[0053] (2) placing the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com