Robot wrist body and preparation method thereof

A robot arm and robot technology, applied in the mechanical field, can solve the problems of difficult to meet the use requirements, poor mechanical properties of aluminum alloys, heavy workload, etc., and achieve the effects of improving connection stability, improving overall performance, and improving activation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

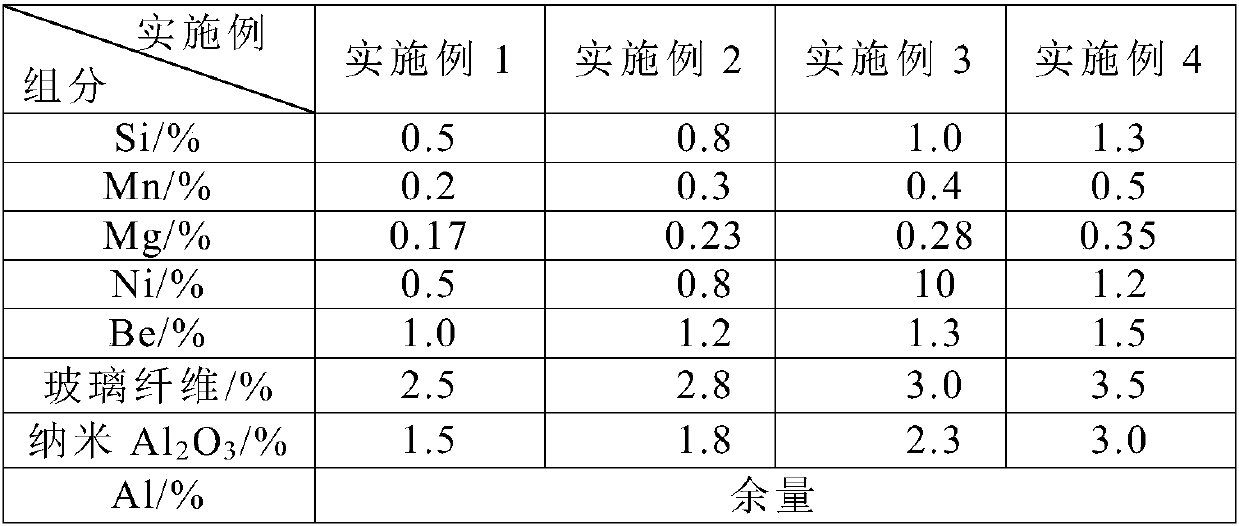

[0030] The robot wrist body in Examples 1-4 is made of aluminum alloy, and the aluminum alloy includes the following components in mass percentage, 0.5-1.3% Si, 0.2-0.5% Mn, 0.17-0.35Mg, 0.5-1.2% Ni, 1.0 -1.5% Be, 2.5-3.5% glass fiber, 1.5-3.0% nano Al 2 o 3 , the balance is Al; the length of the glass fiber is 100-500μm, the diameter is 0.1-10μm; nano-Al 2 o 3 The particle size is 30-80nm.

[0031] The components and mass percentages of the aluminum alloys in Examples 1-4 are shown in the table below.

[0032] Table 1: Components and mass percentages of aluminum alloys in Examples 1-4

[0033]

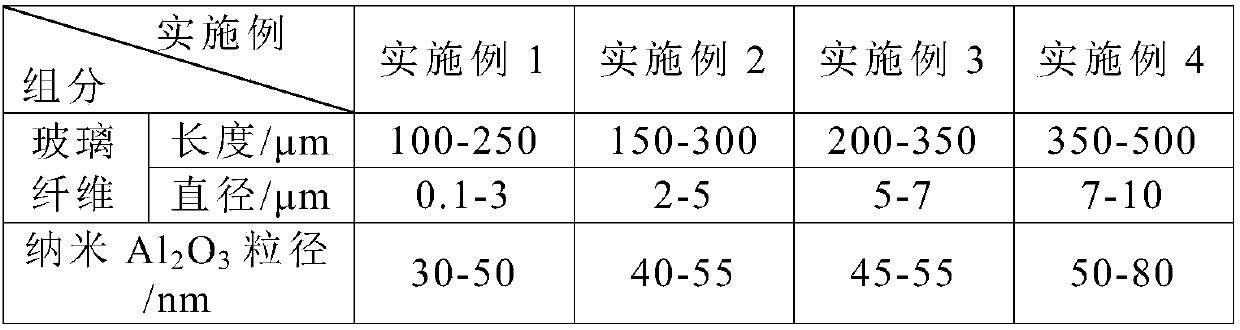

[0034] Glass fiber and nano Al in embodiment 1-4 2 o 3 The dimensions are shown in the table below.

[0035] Table 2: Glass fiber and nanometer Al in embodiment 1-4 2 o 3 size of

[0036]

Embodiment 5

[0038] The preparation method of the robot wrist body in this embodiment includes the following steps,

[0039] (1), prepare the raw material of aluminum alloy according to the ratio of each component in embodiment 3;

[0040] (2), glass fiber and nano-Al 2 o 3 Add them into the activation solution respectively, and carry out ultrasonic stirring treatment at 200w ultrasonic power, 150rmp stirring rate and 30°C temperature. After drying, the glass fiber and nano-Al 2 o 3 respectively added to the modified solution, the mass percentage of glass fiber in the modified solution is 30%, nanometer Al 2 o 3 The mass percentage in the modified liquid is 20%, ultrasonic stirring treatment is carried out at 200w ultrasonic power, 150rmp stirring rate and 50°C temperature, and then the glass fiber is subjected to microwave blast drying, and the nano-Al 2 o 3 carry out spray drying;

[0041] Wherein, the activation solution includes the following components in mass percentage: 0.9% ...

Embodiment 6

[0046] The preparation method of the robot wrist body in this embodiment includes the following steps,

[0047] (1), prepare the raw material of aluminum alloy according to the ratio of each component in embodiment 3;

[0048] (2), glass fiber and nano-Al 2 o 3 Add them into the activation solution respectively, and carry out ultrasonic stirring treatment at 250w ultrasonic power, 130rmp stirring rate and 35°C temperature. After drying, the glass fiber and nano-Al 2 o 3 respectively added to the modified solution, the mass percentage of glass fiber in the modified solution is 33%, nanometer Al 2 o 3 The mass percentage in the modified solution is 22%, ultrasonic stirring treatment is carried out at 250w ultrasonic power, 130rmp stirring rate and 55 ° C temperature, and then the glass fiber is subjected to microwave blast drying, and the nano-Al 2 o 3 carry out spray drying;

[0049] Wherein, the activation solution includes the following components in mass percentage: 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com