A copper-steel composite pipe and its preparation method

A technology of copper-steel composite and composite pipes, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of small diffusion bonding layer, difficulty in improving bonding strength, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

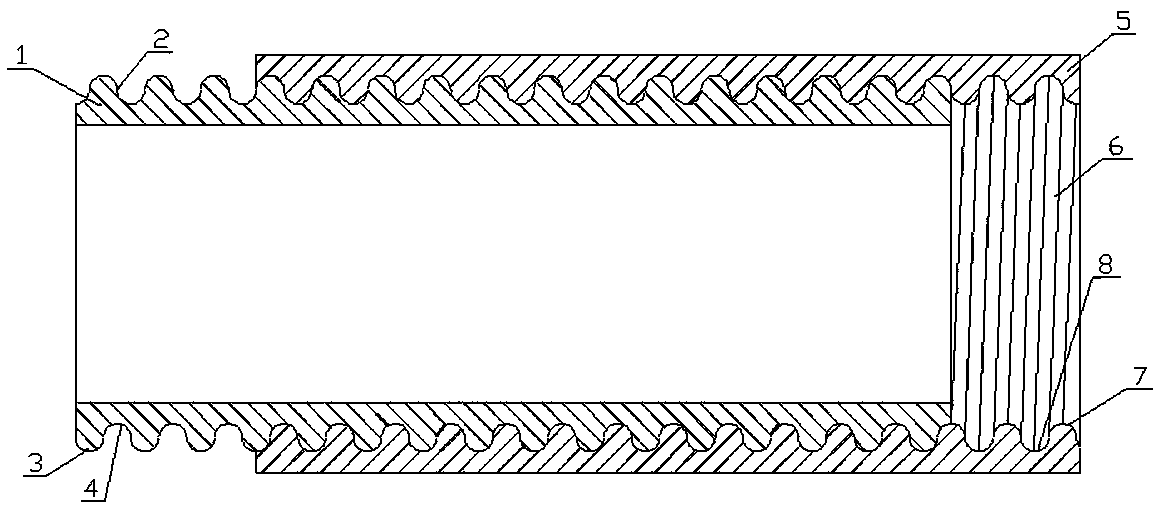

[0016] A preparation method of a copper-steel composite pipe, the structure of the copper-steel composite pipe is as follows figure 1 As shown, it consists of copper pipe 1 and steel pipe 5. Copper pipe thread teeth 2 are formed on the outer periphery of the copper pipe 1, and the copper pipe thread teeth 2 are composed of semicircular copper pipe thread tooth peaks 3 and semicircular copper pipe thread tooth valleys 4 with a radius of 0.2-0.5mm. The inner ring of the steel pipe 5 opens the steel pipe thread tooth 6, and the steel pipe thread tooth 6 is composed of a semicircular steel pipe thread peak 7 and a semicircular steel pipe thread valley 8 with a radius of 0.2-0.5mm. Degrease the surface of copper tube 1 and steel tube 5 with 10% NaOH solution. Rotate the copper pipe 1 and the steel pipe 5 with matching sizes in reverse, and use the copper pipe thread teeth 2 of the copper pipe 1 and the steel pipe thread teeth 6 of the steel pipe 5 to realize the reverse screwing o...

example 1

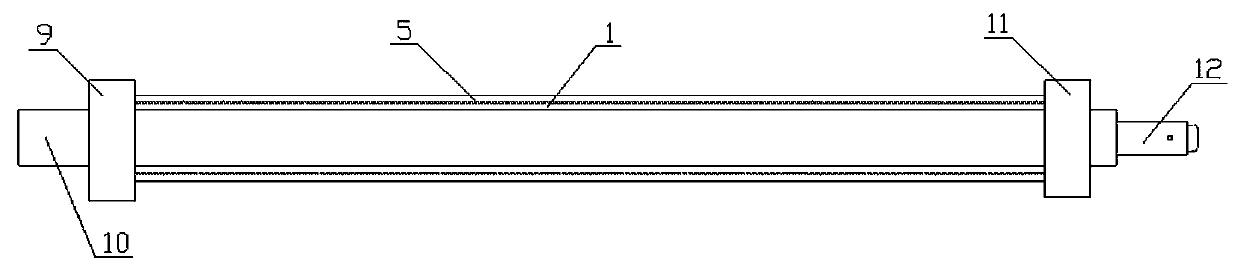

[0019] 20 steel with an outer diameter of 32 mm and a wall thickness of 4 mm and a pure copper tube with an outer diameter of 28.6 mm and a wall thickness of 1.0 mm are used as the outer tube and the copper tube as the inner tube. Both materials are annealed. Use a lathe to open the internal thread of the steel pipe. The shape of the crest and valley of the thread is a semicircle with a radius of 0.3mm. After cleaning with a 10% NaOH solution by mass fraction, dry it with cold air, and tighten the thread to form a composite pipe. ; Nitrogen gas is fed into the gas nozzle 10 of the composite pipe. When the pressure in the pipe reaches 2.3 MPa, the pressure relief valve opens the pressure relief mode, heats in the electromagnetic induction coil, stops heating, and cools the ferrule joint 9 and the inlet end with cooling water. Use a temperature measuring gun to measure the temperature of the ferrule joint 11 at the gas outlet, and keep the temperature at about 800°C. After heatin...

example 2

[0021] 20 steel with an outer diameter of 57 mm and a wall thickness of 4 mm and a pure copper tube with an outer diameter of 53.98 mm and a wall thickness of 1.5 mm are used as the outer tube and the copper tube as the inner tube. Both materials are annealed. Use a lathe to open the internal thread of the steel pipe. The shape of the crest and valley of the thread is a semicircle with a radius of 0.5mm. After cleaning with a 10% NaOH solution by mass fraction, dry it with cold air, and tighten the thread to form a composite pipe. ; Nitrogen gas is introduced into the gas nozzle 10 of the composite pipe. When the pressure in the pipe reaches 1.8 MPa, the pressure relief valve opens the pressure relief mode, heats in the electromagnetic induction coil, stops heating, and cools the ferrule joint 9 at the intake end with cooling water. For the ferrule joint 11 at the outlet end, use a temperature measuring gun to measure the temperature, keep the temperature at about 900 °C, stop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com