A method of increasing the bursting temperature of pellets made of ultra-fine iron concentrate

A technology of pelletizing ore and iron concentrate, which is applied in the field of improving the bursting temperature of ultra-fine iron concentrate pellets and the production of ironmaking raw material pellets. It can solve the problems of low pelletizing temperature and high manufacturing cost, and achieve improvement. Particle size distribution, guaranteed adaptability, and the effect of increasing the burst temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

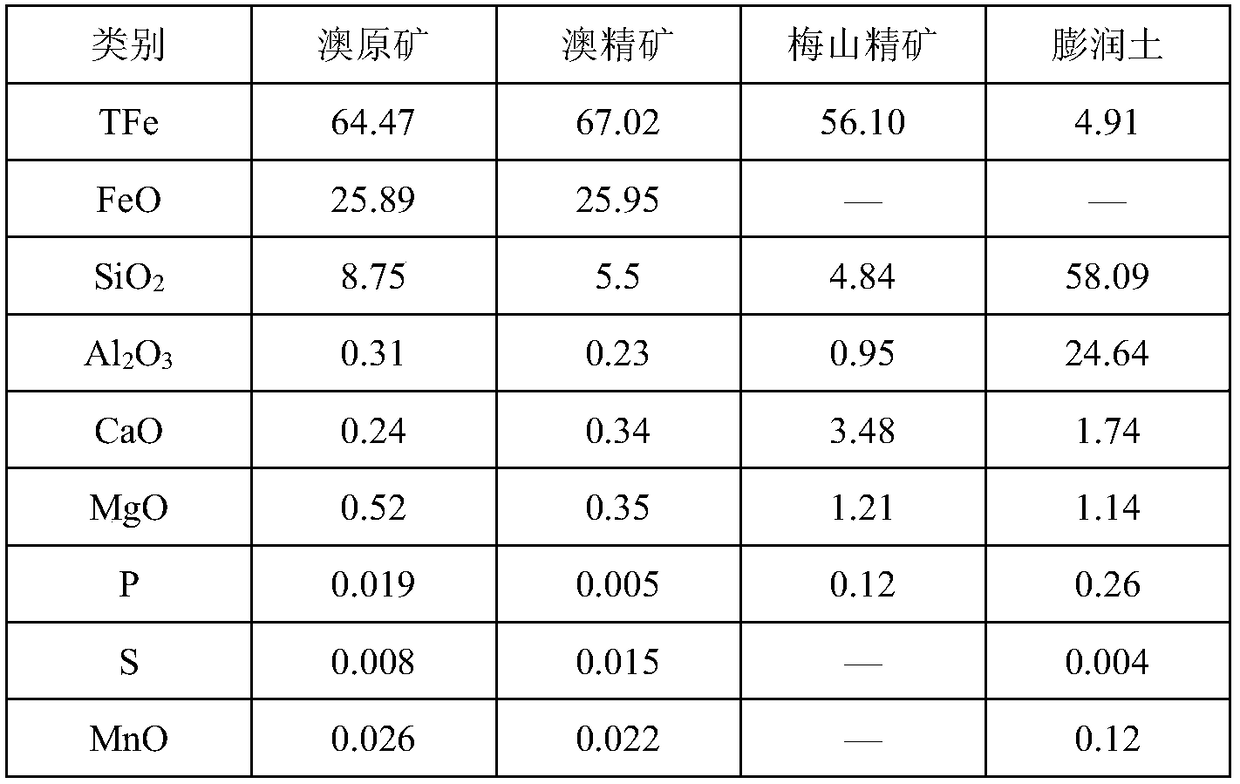

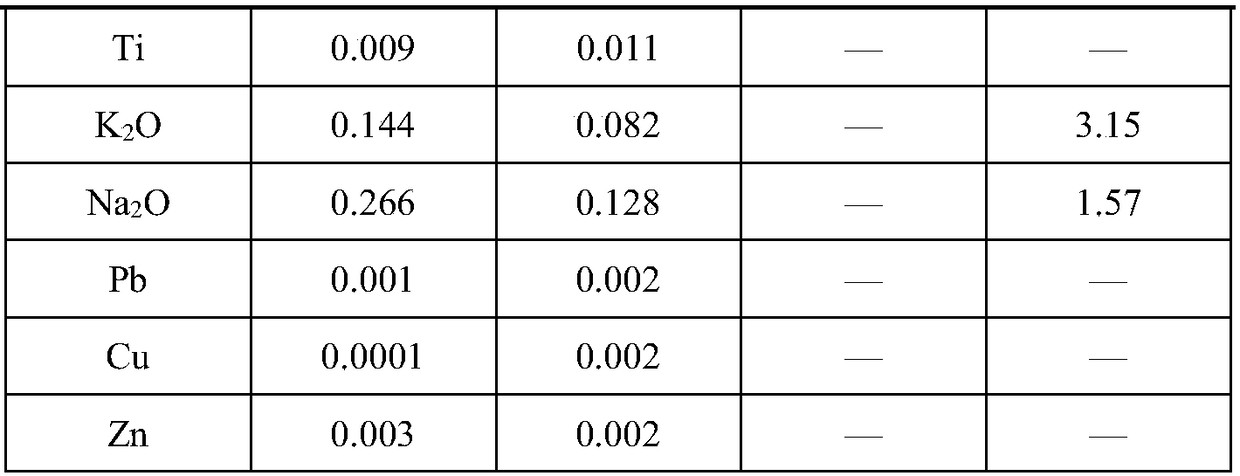

[0022] Embodiment 1, 30% of the pellet inner layer material, 70% of the pellet outer layer material; the percentage by weight of each component of the pellet ore inner layer material is: 32.4% of the original Australian ore, 17.6% of the Australian concentrate, and 17.6% of the Meishan concentrate 49.0%, bentonite 1.0%; the weight percentages of the components of the pellet outer layer are: Australian raw ore 63.7%, Australian concentrate 35.3%, bentonite 1.0%; components of different particle sizes in Australian raw ore, Australian concentrate and Meishan concentrate The weight percentage is shown in Table 2,

[0023] The percentage by weight of different particle size components in the raw material of table 2 embodiment 1, %

[0024] category

>0.074mm

0.074-0.043mm

0.043-0.037mm

<0.037mm

Australian ore

0.60

3.40

4.90

91.10

Australian Concentrate

0.05

5.45

5.50

89.00

Meishan Concentrate

36.00

19.20

...

Embodiment 2

[0040] Embodiment 2, the basic content of embodiment 2 is as embodiment 1, and its difference is: the percentage by weight of each component of pellet outer layer material is: Australian raw ore 63.5%, Australian concentrate 35.3%, bentonite 1.2%. The detonation temperature of the pellets obtained in Example 2 is 375°C.

[0041] Compared with Example 1, although the bentonite in the outer layer of pellets in Example 2 is only increased from 1.0% to 1.2%, the bursting temperature of the pellets is significantly improved. Thereby increasing the strength of the green pellets and the tensile strength of the dry shell, so that the excess vapor pressure generated by the drying front in the inner pellets is smaller than the tensile strength of the green pellets and the dry shell, thereby significantly improving the iron concentrate oxide pellets. burst temperature of the cluster.

Embodiment 3

[0042] Embodiment 3, the basic content of embodiment 3 is as embodiment 1, and its difference is: the percentage by weight of each constituent of pellet inner layer material is: Australian raw ore 30.0%, Australian concentrated ore 15.0%, Meishan concentrated ore 54.25% %, bentonite 0.75%; the percentage by weight of each component of the pellet outer layer material is: 58.5% of Australian raw ore, 40.0% of Australian concentrate, 1.5% of bentonite, and the bursting temperature of the pellet obtained in Example 3 is 362°C. Example 3 See Table 5 for the weight percentages of components with different particle sizes in the pellet inner layer material and outer layer material.

[0043] Table 5 Example 3 Pellet inner layer material and the weight percentage of different particle size components in the outer layer material, %

[0044] category

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com