A flotation tailing coal-based metallurgical pellet binder and its preparation method

A flotation tail coal and binder technology, applied in the field of mineral processing, can solve problems such as metallurgical pellet binders that have not yet been found, and achieve the effects of long separation time, reduced pollution, and reduced land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

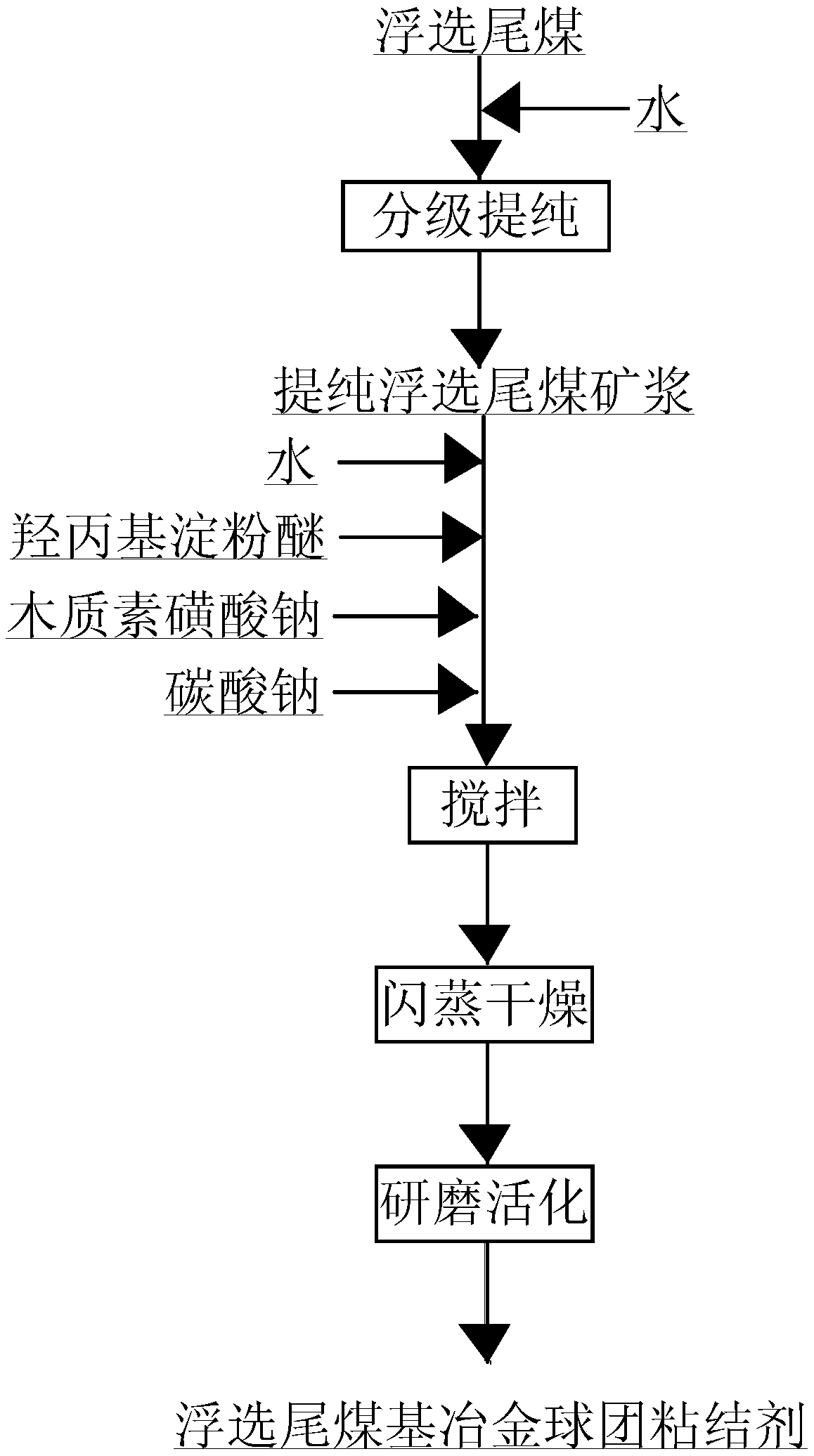

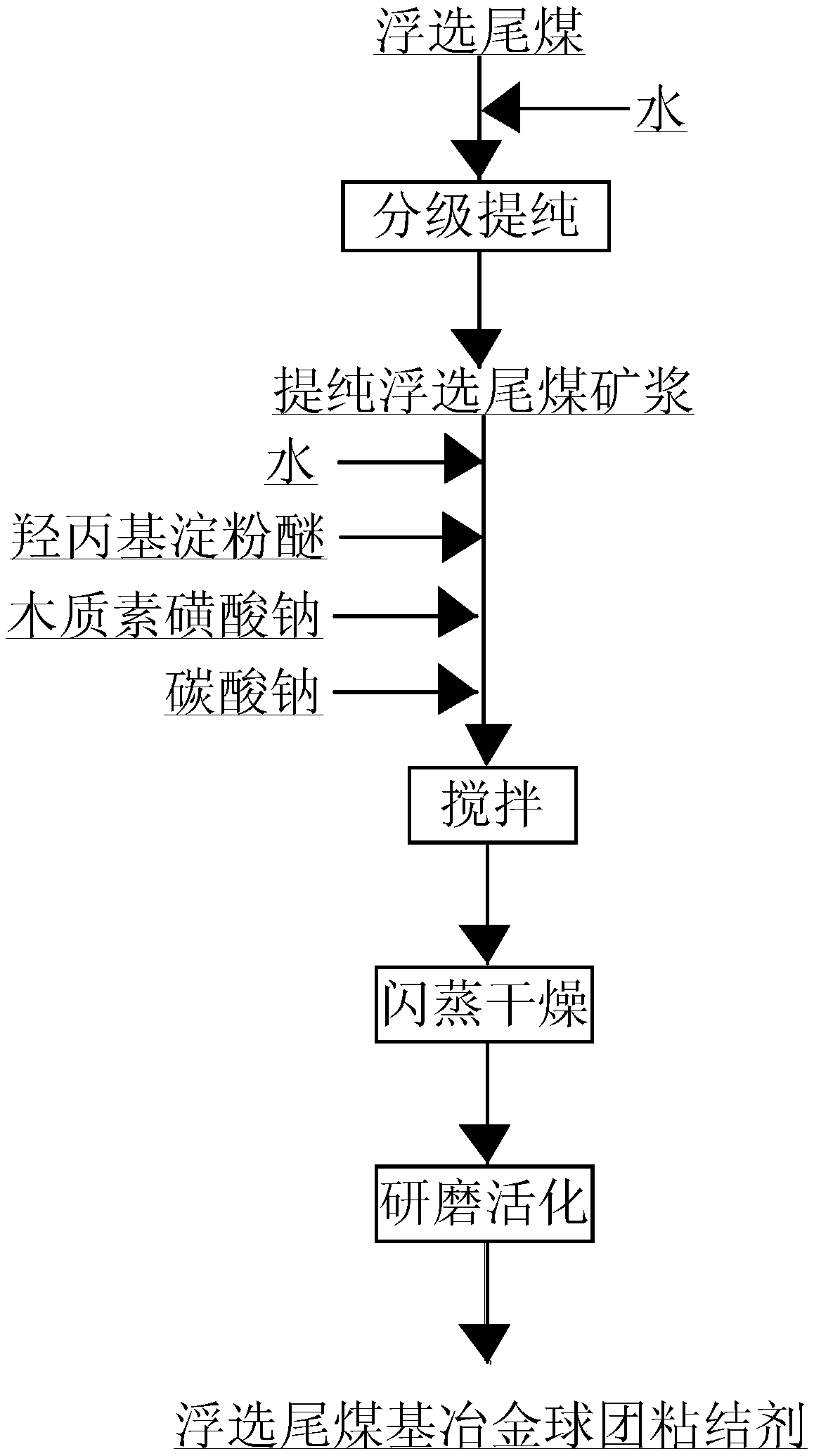

Image

Examples

Embodiment 1

[0032] The components of the metallurgical pellet binder based on flotation tailings are as follows by weight: 85% of purified flotation tails, 8% of hydroxypropyl starch ether, 2% of sodium lignosulfonate, and 5% of sodium carbonate; uniform particle size ≤0.045mm;

[0033] The preparation method is:

[0034] The flotation tailings with particle size ≤0.074mm and montmorillonite weight percentage of more than 50% are added with water to make a primary slurry with a weight concentration of 15%, which is then classified and purified by a cyclone group to obtain montmorillonite in the flotation tailings. 70% by weight to obtain a purified flotation tailing coal slurry with a weight concentration of 30%;

[0035] The purified flotation tailing coal mine slurry is added with water to make a secondary slurry with a weight concentration of 20%, and then hydroxypropyl starch ether, sodium lignosulfonate and sodium carbonate with a particle size of ≤0.074mm are added in the above proportion...

Embodiment 2

[0038] The components of the metallurgical pellet binder based on flotation tailings are as follows in weight percentage: purified flotation tailings 90%, hydroxypropyl starch ether 5%, sodium lignosulfonate 2%, sodium carbonate 3%; particle size is uniform ≤0.045mm;

[0039] The preparation method is:

[0040] The flotation tailings with particle size ≤0.074mm and montmorillonite weight percentage of 51% or more are added with water to make a primary slurry with a weight concentration of 16%, which is then graded and purified by a cyclone group to obtain montmorillonite in the flotation tailings. 71% by weight to obtain a purified flotation tailing coal slurry with a weight concentration of 31%;

[0041] The purified flotation tailing coal mine slurry is supplemented with water to make a 21% weight concentration secondary slurry, and then hydroxypropyl starch ether, sodium lignosulfonate and sodium carbonate with a particle size ≤0.074mm are added in the above proportions, and the ...

Embodiment 3

[0044] The components of the metallurgical pellet binder based on flotation tailings are as follows: 87% of purified flotation tails, 6% of hydroxypropyl starch ether, 3% of sodium lignosulfonate, 4% of sodium carbonate; uniform particle size ≤0.045mm;

[0045] The preparation method is:

[0046] The flotation tailings with a particle size of ≤0.074mm and a weight percentage of montmorillonite of more than 53% are added with water to make a primary slurry with a weight concentration of 17%, which is then graded and purified by a cyclone group to obtain montmorillonite in the flotation tailings. 73% by weight to obtain a purified flotation tailing coal slurry with a weight concentration of 32%;

[0047] The purified flotation tailing coal mine slurry is added with water to make a secondary slurry with a weight concentration of 22%, and then hydroxypropyl starch ether, sodium lignosulfonate and sodium carbonate with a particle size of ≤0.074mm are added according to the above ratio, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com