A kind of preparation method and application of hyperbranched polyimide anticoagulant antibacterial material

A technology of polyimide and antibacterial materials, which is applied in the field of preparation of hyperbranched polyimide anticoagulant antibacterial materials, and can solve problems such as insufficient biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

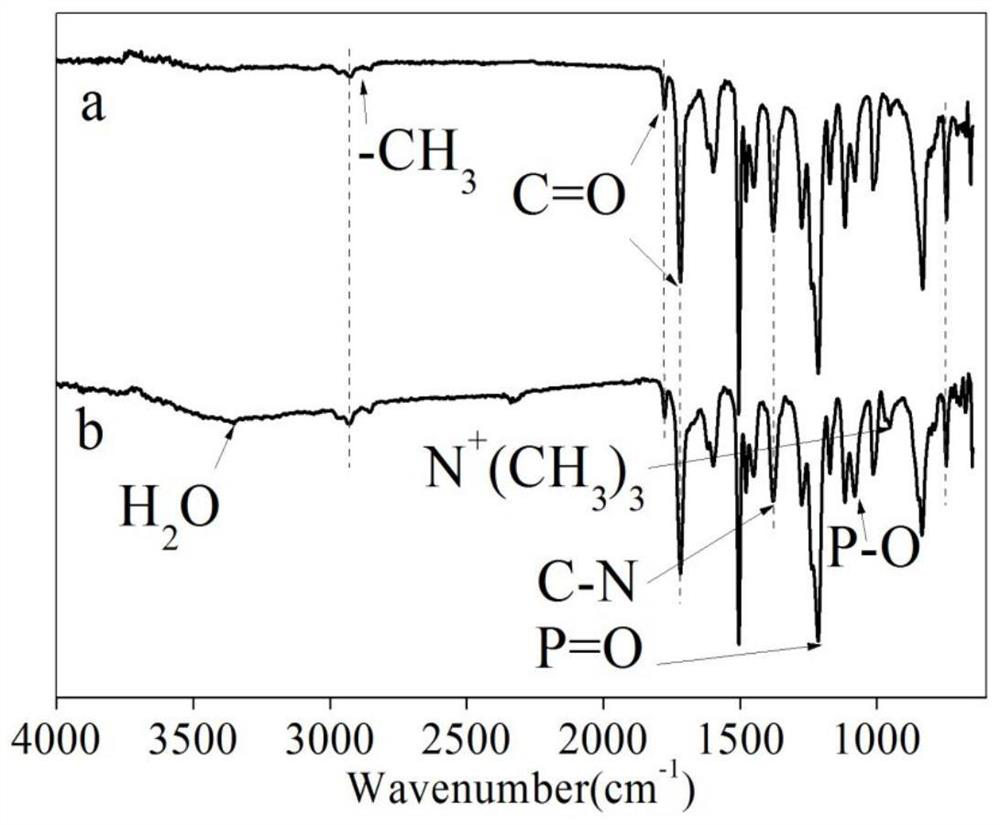

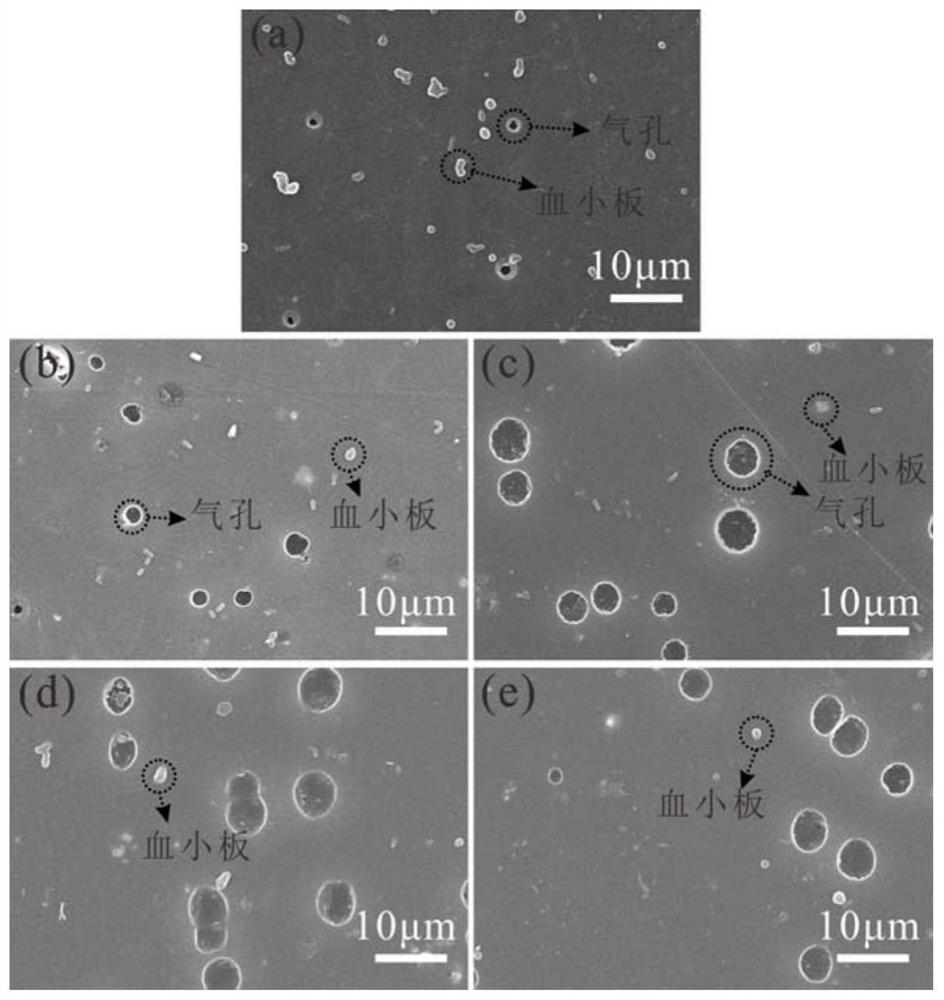

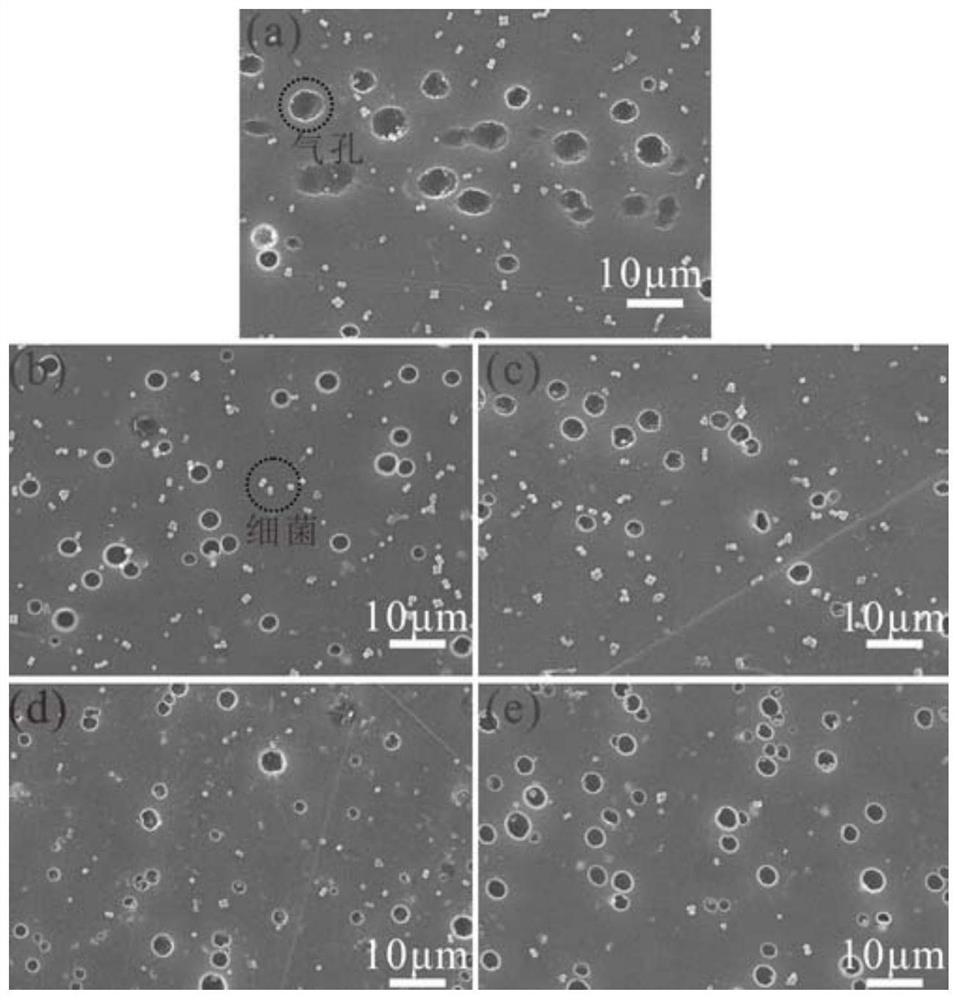

[0016] One of purpose of the present invention is to provide a kind of preparation method of hyperbranched polyimide anticoagulant antibacterial material, at first synthesize the hyperbranched polyimide (AM-HBPI) of amino termination, then use 2-methacryloyl Oxyethylphosphorylcholine (MPC) was grafted on its surface to form a HBPI-MPC film, and its anticoagulation, antibacterial and biocompatibility were characterized. The specific steps are as follows:

[0017] (1) Preparation of amino-terminated hyperbranched polyimide (AM-HBPI): 1,3,5-tris(4-aminophenoxy)benzene (TAPOB) and N-methylpyrrolidone (NMP) were placed in a flask with magnetic stirring, cooled in an ice bath, under N 2 Under protection, use a constant pressure dropping funnel to slowly drop the mixed solution of bisphenol A dianhydride (BPADA) and N-methylpyrrolidone (NMP) into it within 1 to 3 hours, and react at room temperature for 1 ~2h, add isoquinoline dropwise, react at 120°C for 3~5h, react at 180~200°C fo...

Embodiment 1

[0028] (1) Preparation of amino-terminated hyperbranched polyimide (AM-HBPI): 0.399g (1mmol) 1,3,5-tris(4-aminophenoxy)benzene (TAPOB) and 10ml N-methyl Nylpyrrolidone (NMP) was placed in a 100ml three-necked flask, magnetically stirred, cooled in an ice bath, and placed in a N 2 Under protection, use a constant pressure dropping funnel to slowly drop a mixed solution of 0.520g (1mmol) bisphenol A dianhydride (BPADA) and 10ml N-methylpyrrolidone (NMP) into it within 2h. React at room temperature for 1 hour, add 6 drops of isoquinoline dropwise, react at 120°C for 5 hours, and react at 180°C for 18 hours. terminal hyperbranched polyimide (AM-HBPI).

[0029] (2) AM-HBPI film grafting modification: the AM-HBPI powder of 0.6g is dissolved in 10mlNMP, the aqueous solution ( where mol%=n(MPC) / n(HBPI)*100%), stirred at room temperature for 24h, spread the mixed solution on a dry and clean glass plate, then dried in a drying oven, baked at 100°C for 18h, and removed the solvent ; T...

Embodiment 2

[0032] (1) Preparation of amino-terminated hyperbranched polyimide (AM-HBPI): the method is the same as in Example 1.

[0033] (2) AM-HBPI film grafting modification: the AM-HBPI powder of 0.6g is dissolved in 10mlNMP, the aqueous solution ( where mol%=n(MPC) / n(HBPI)*100%), stirred at room temperature for 26h, spread the mixed solution on a dry and clean glass plate, then dried in a drying oven, baked at 100°C for 24h, and removed the solvent Gradiently increase the temperature to 160° C. and 220° C., keep warm for 2 hours respectively, and finally cool naturally to obtain a hyperbranched polyimide film (HBPI-MPC film).

[0034] (3) Finally, the film of step (2) was shaken in deionized water at room temperature for 8 hours to remove ungrafted MPC on the surface of the film. This shaking cleaning step was repeated 3 times; finally, the gained HBPI-MPC film was placed at room temperature Vacuum dried to constant weight, named HBPI-10MPC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com