Preparation method and application of hyperbranched polyimide anti-coagulant antibacterial material

A technology of polyimide and antibacterial materials, which is applied in the field of preparation of hyperbranched polyimide anticoagulant antibacterial materials, can solve the problems of insufficient biocompatibility, and achieve the goal of preventing various complications and bacterial infection , strong anticoagulant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

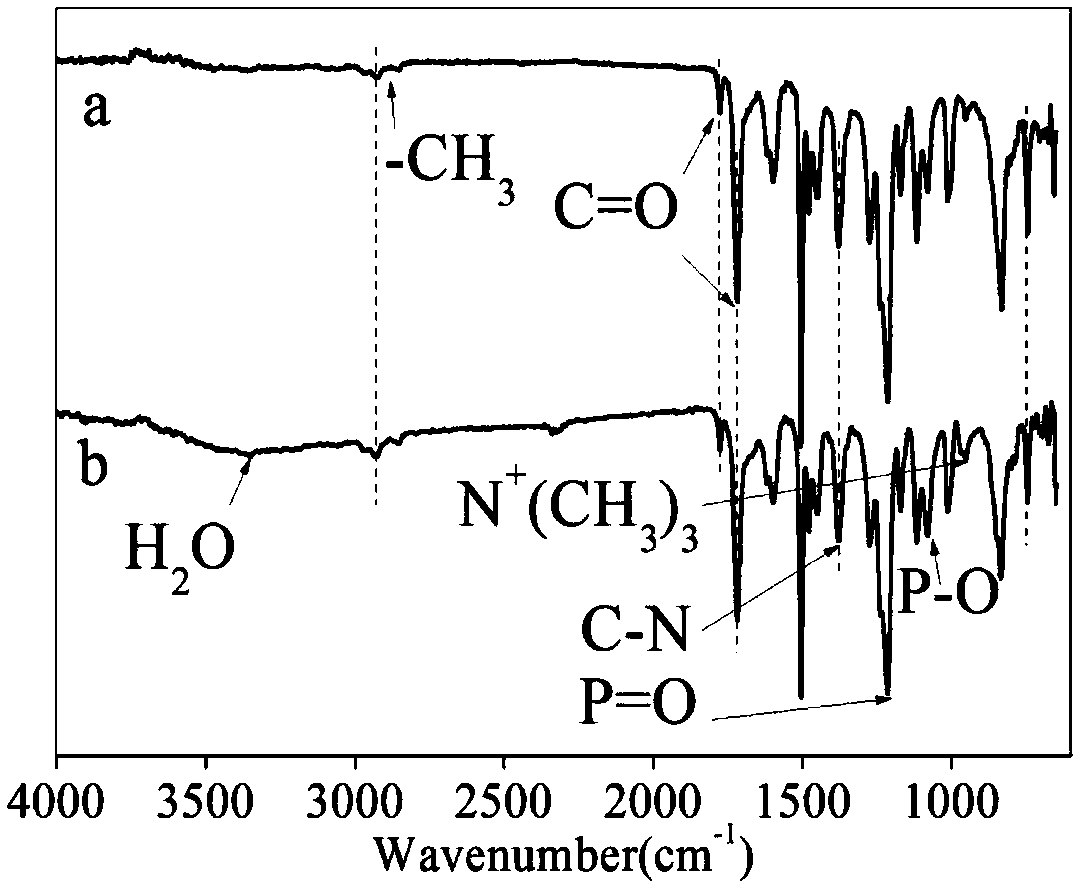

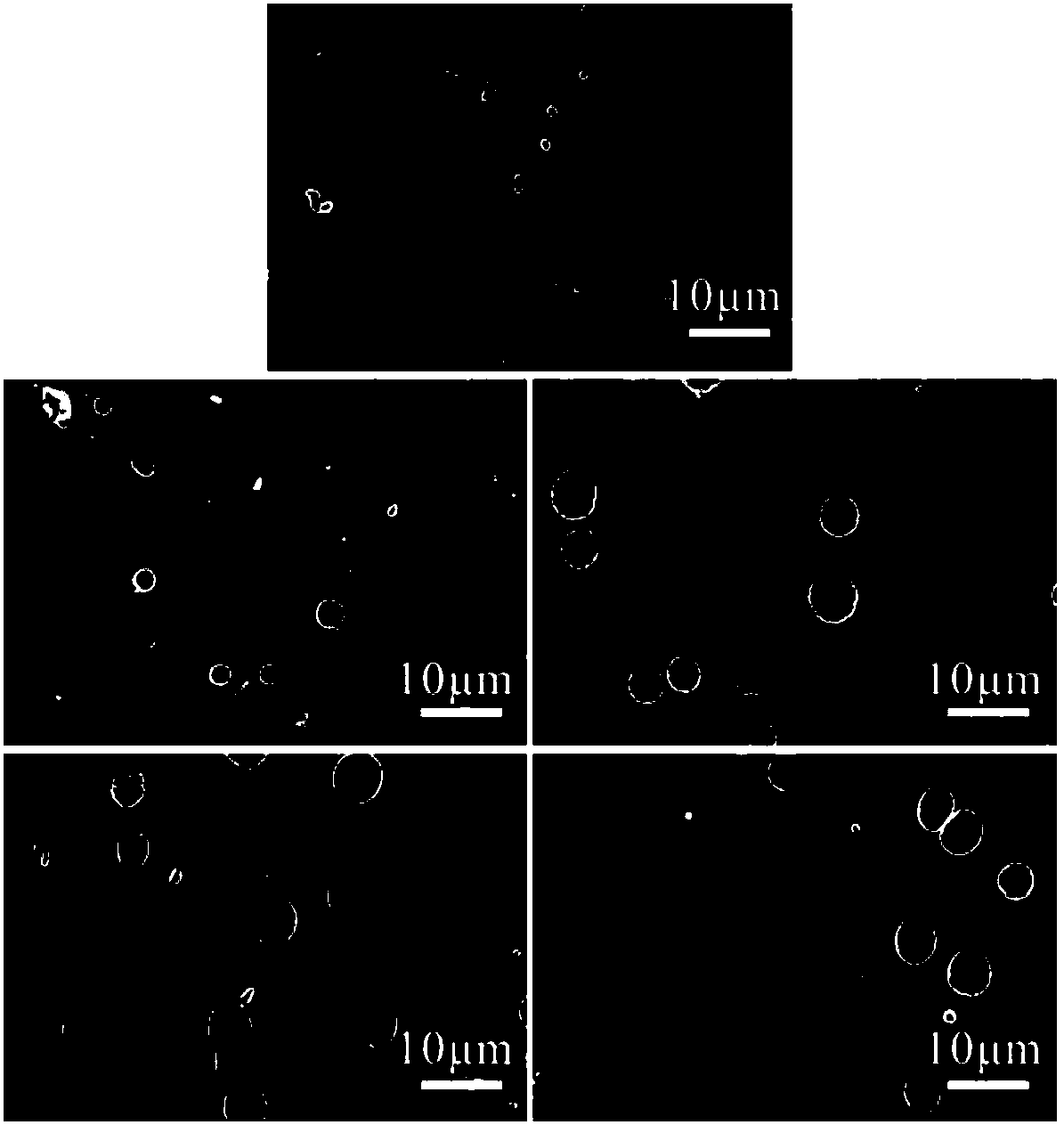

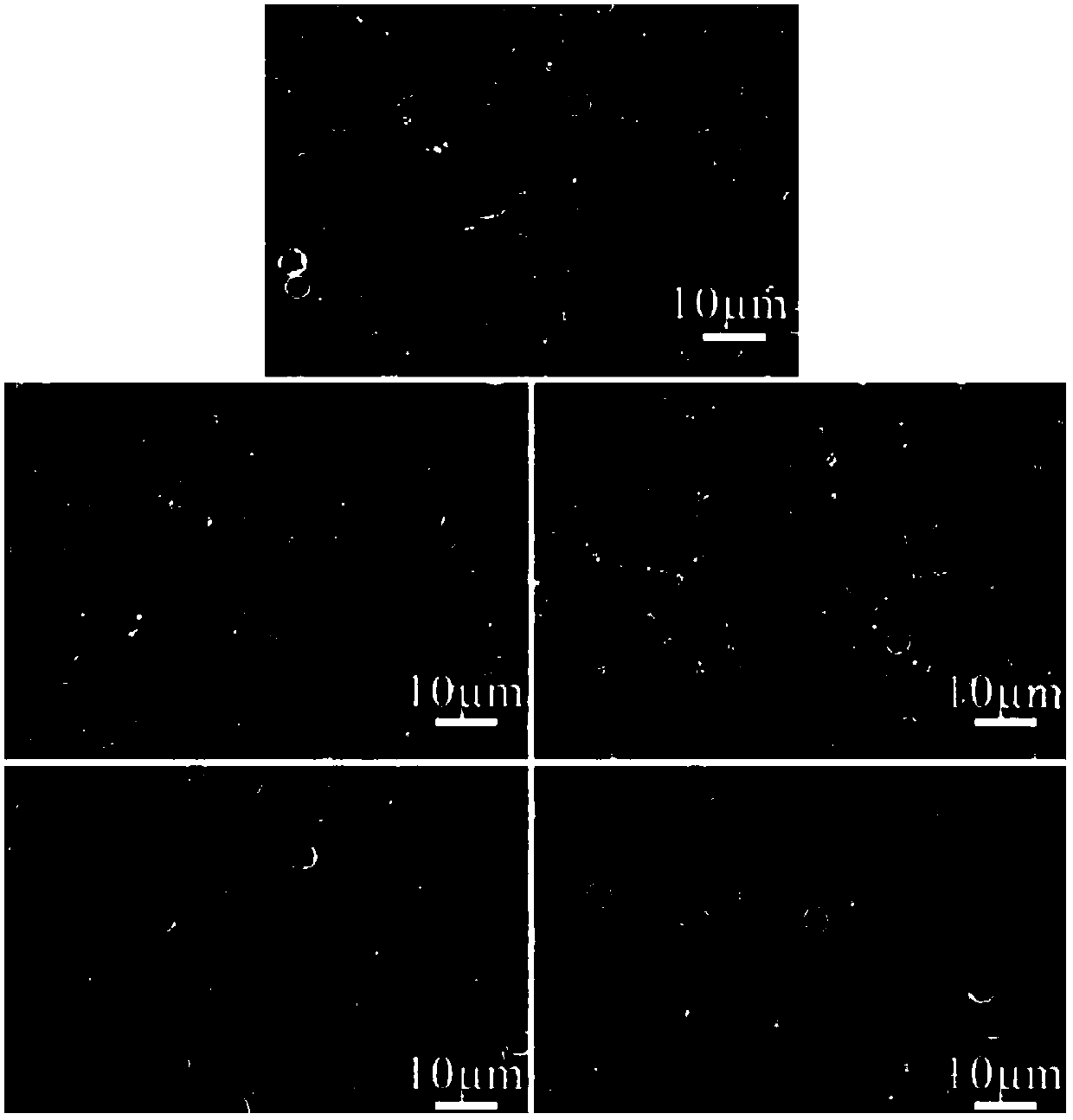

[0015] One of purpose of the present invention is to provide a kind of preparation method of hyperbranched polyimide anticoagulant antibacterial material, at first synthesize the hyperbranched polyimide (AM-HBPI) of amino termination, then use 2-methacryloyl Oxyethylphosphorylcholine (MPC) was grafted on its surface to form a HBPI-MPC film, and its anticoagulation, antibacterial and biocompatibility were characterized. The specific steps are as follows:

[0016] (1) Preparation of amino-terminated hyperbranched polyimide (AM-HBPI): 1,3,5-tris(4-aminophenoxy)benzene (TAPOB) and N-methylpyrrolidone (NMP) were placed in a flask with magnetic stirring, cooled in an ice bath, under N 2 Under protection, use a constant pressure dropping funnel to slowly drop the mixed solution of bisphenol A dianhydride (BPADA) and N-methylpyrrolidone (NMP) into it within 1 to 3 hours, and react at room temperature for 1 ~2h, add isoquinoline dropwise, react at 120°C for 3~5h, react at 180~200°C fo...

Embodiment 1

[0027] (1) Preparation of amino-terminated hyperbranched polyimide (AM-HBPI): 0.399g (1mmol) 1,3,5-tris(4-aminophenoxy)benzene (TAPOB) and 10ml N-methyl Nylpyrrolidone (NMP) was placed in a 100ml three-necked flask, magnetically stirred, cooled in an ice bath, and placed in a N 2 Under protection, use a constant pressure dropping funnel to slowly drop a mixed solution of 0.520g (1mmol) bisphenol A dianhydride (BPADA) and 10ml N-methylpyrrolidone (NMP) into it within 2h. React at room temperature for 1 hour, add 6 drops of isoquinoline dropwise, react at 120°C for 5 hours, and react at 180°C for 18 hours. terminal hyperbranched polyimide (AM-HBPI).

[0028] (2) AM-HBPI film grafting modification: the AM-HBPI powder of 0.6g is dissolved in 10mlNMP, the aqueous solution ( where mol%=n(MPC) / n(HBPI)*100%), stirred at room temperature for 24h, spread the mixed solution on a dry and clean glass plate, then dried in a drying oven, baked at 100°C for 18h, and removed the solvent ; G...

Embodiment 2

[0031] (1) Preparation of amino-terminated hyperbranched polyimide (AM-HBPI): the method is the same as in Example 1.

[0032] (2) AM-HBPI film grafting modification: the AM-HBPI powder of 0.6g is dissolved in 10mlNMP, the aqueous solution ( where mol%=n(MPC) / n(HBPI)*100%), stirred at room temperature for 26h, spread the mixed solution on a dry and clean glass plate, then dried in a drying oven, baked at 100°C for 24h, and removed the solvent Gradiently increase the temperature to 160° C. and 220° C., keep warm for 2 hours respectively, and finally cool naturally to obtain a hyperbranched polyimide film (HBPI-MPC film).

[0033] (3) Finally, the film of step (2) was shaken in deionized water at room temperature for 8 hours to remove ungrafted MPC on the surface of the film. This shaking cleaning step was repeated 3 times; finally, the gained HBPI-MPC film was placed at room temperature Vacuum dried to constant weight, named HBPI-10MPC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com