Microwave thermal imaging nondestructive testing system based on matrix decomposition and testing method

A matrix decomposition and non-destructive testing technology, applied in the direction of using microwave flaw detection, etc., can solve the problems of separation and sub-surface defect damage area difficult to quantify effectively, temperature aliasing cannot be located, etc., to achieve defect detection and depth quantification, effect Long distance and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

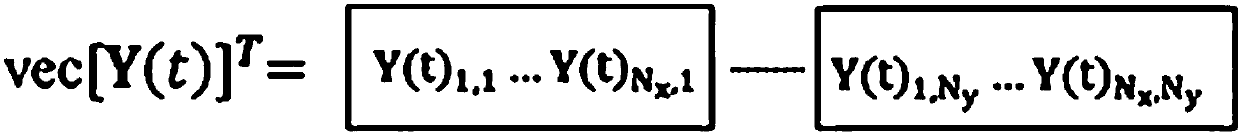

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] Such as figure 1 As shown, the microwave thermal imaging nondestructive testing system based on matrix decomposition includes a microwave excitation device and a thermal imaging monitoring device; the microwave excitation device includes a microwave signal generator 1, a microwave signal amplifier 2, a microwave excitation sensor 3 and a wave-absorbing material 4; The imaging monitoring device includes a thermal imager 5 and a data acquisition and processing device 6; the data acquisition and processing device is respectively connected with the microwave signal generator and the thermal imager, so as to obtain the temperature change data of the measured object.

[0038] Preferably, the microwave excitation sensor 3 adopts a horn antenna and a rectangular opening waveguide.

[0039] The following is a specific description:

[0040] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com