Method for improving gas extraction rate by extracting geothermic energy

A gas drainage and energy extraction technology, applied in geothermal power generation, heat collectors without external energy operation, etc., can solve the problems of poor thermal conductivity of coal, high energy consumption and cost of gas, and achieve high heating efficiency and wide application The effect of sex and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

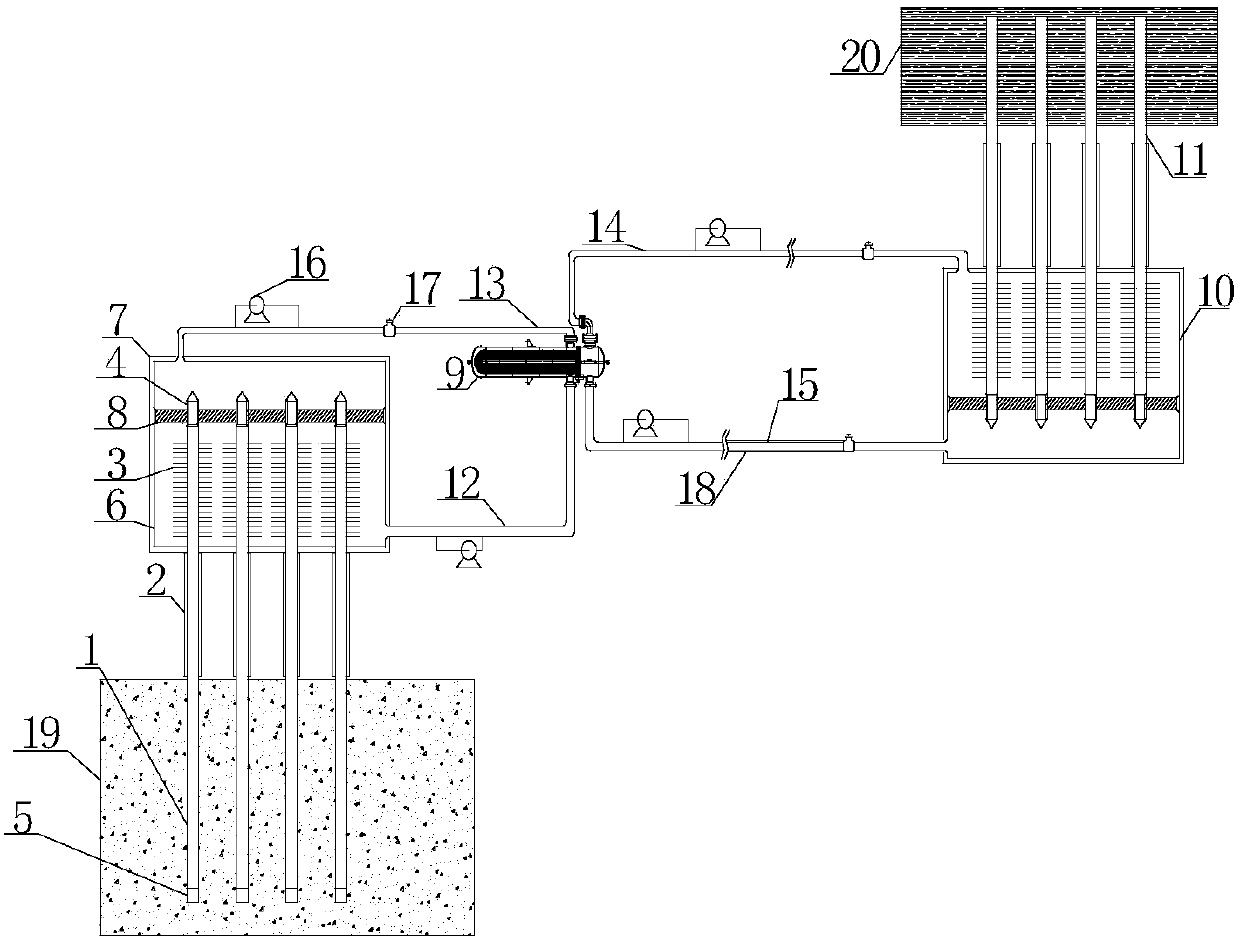

[0024] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as figure 1 As shown, the geothermal energy extraction of the present invention improves the method for gas drainage efficiency, and the specific steps are as follows:

[0026] a) A plurality of boreholes are constructed at intervals in the heat source area 19 of the mine, and a collector heat pipe 1 is buried in each borehole. A heat pipe insulation layer 2 is provided on the heat collecting heat pipe section of the inlet section of the tank 6, fins 3 are arranged on the heat collecting heat pipe section 1 arranged in the heat collecting heat tank 6, and an end cover 4 is provided on the head of the heat collecting heat pipe 1 , the end cover 4 is fixed on the copper heat pipe 8 in the water collecting tank 6 through threaded connection, multiple heat collecting heat pipes are fixed in series through the copper heat pipe 8, and the holes are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com