Construction method of non-excavation expansion clinging-type repair pipeline

A construction method and non-excavation technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of complex construction, affecting flow capacity, and large loss of cross-sectional area, so as to reduce construction costs, Accelerate the construction progress, the effect of strong flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0034] A construction method for non-excavation expansion and close-fitting pipeline repair, which is innovative in that it includes the following steps:

[0035] 1). Construction preparation: close the working space, arrange the profile winding frame, lubricating and sealing agent injection pump, control device and steel wire drawing machine at the wellhead of the existing initial inspection well. In-well assembly expansion and close-fitting winding machine;

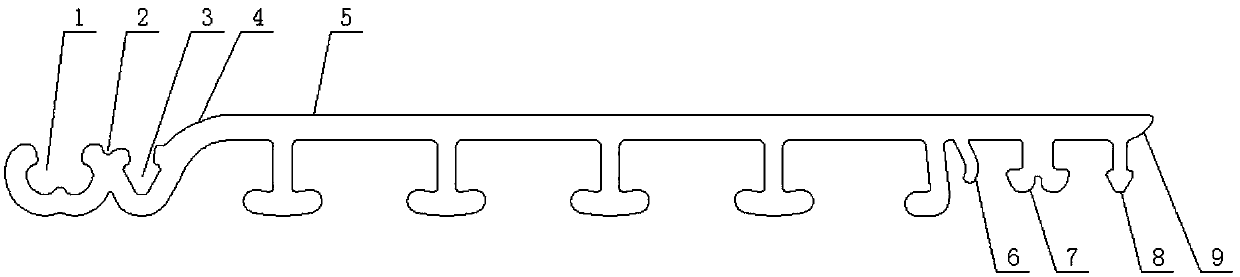

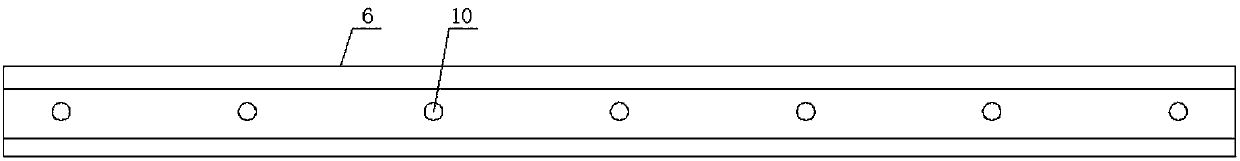

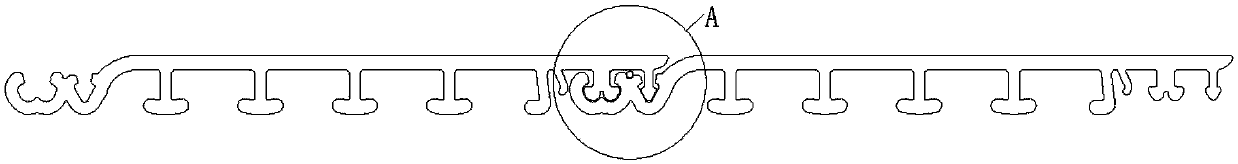

[0036] 2). Winding pipe making: the new strip-shaped profile is transported to the expansion and close-fitting winding machine in the initial inspection well, and a pipe body with a diameter smaller than the original pipe is wound in a spiral winding manner. The pasting winding machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com