Environment-friendly concrete water-based epoxy repair mortar

An environmentally friendly concrete and repair mortar technology, applied in the field of building materials, can solve the problems of affecting material performance, high requirements for the base layer, and high toxicity, etc., achieve good compressive strength and flexural strength, expand the application range, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

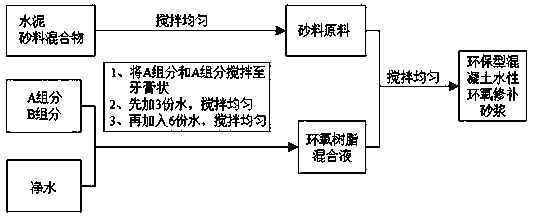

[0016] The invention provides a kind of water-based epoxy repair mortar, its production process flow chart, as figure 1 Shown, this water-based epoxy repair mortar is specifically made according to the following steps:

[0017] 1) In parts by weight, take 90 parts of bisphenol A epoxy resin and 10 parts of C12-14 alkyl glycidyl ether, mix and stir evenly to obtain component A;

[0018] Bisphenol A epoxy resin adopts liquid E-51 bisphenol A epoxy resin;

[0019] According to mass percentage, respectively take 99.35% of non-ionic modified polyamine curing agent, 0.5% of wetting agent and 0.15% of defoamer, mix and disperse evenly to obtain component B;

[0020] 2) According to the weight ratio of 1:1, take quartz sand with a particle size of 20-40 mesh and quartz sand with a particle size of 40-80 mesh, and mix them evenly to obtain a mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com