Hollow and micropore repair construction method of wear-resisting emery ground

A wear-resistant diamond and emery technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of lengthening construction period, consuming manpower and material resources, and not being environmentally friendly, so as to achieve simple preparation work, fast time, and reduce construction investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

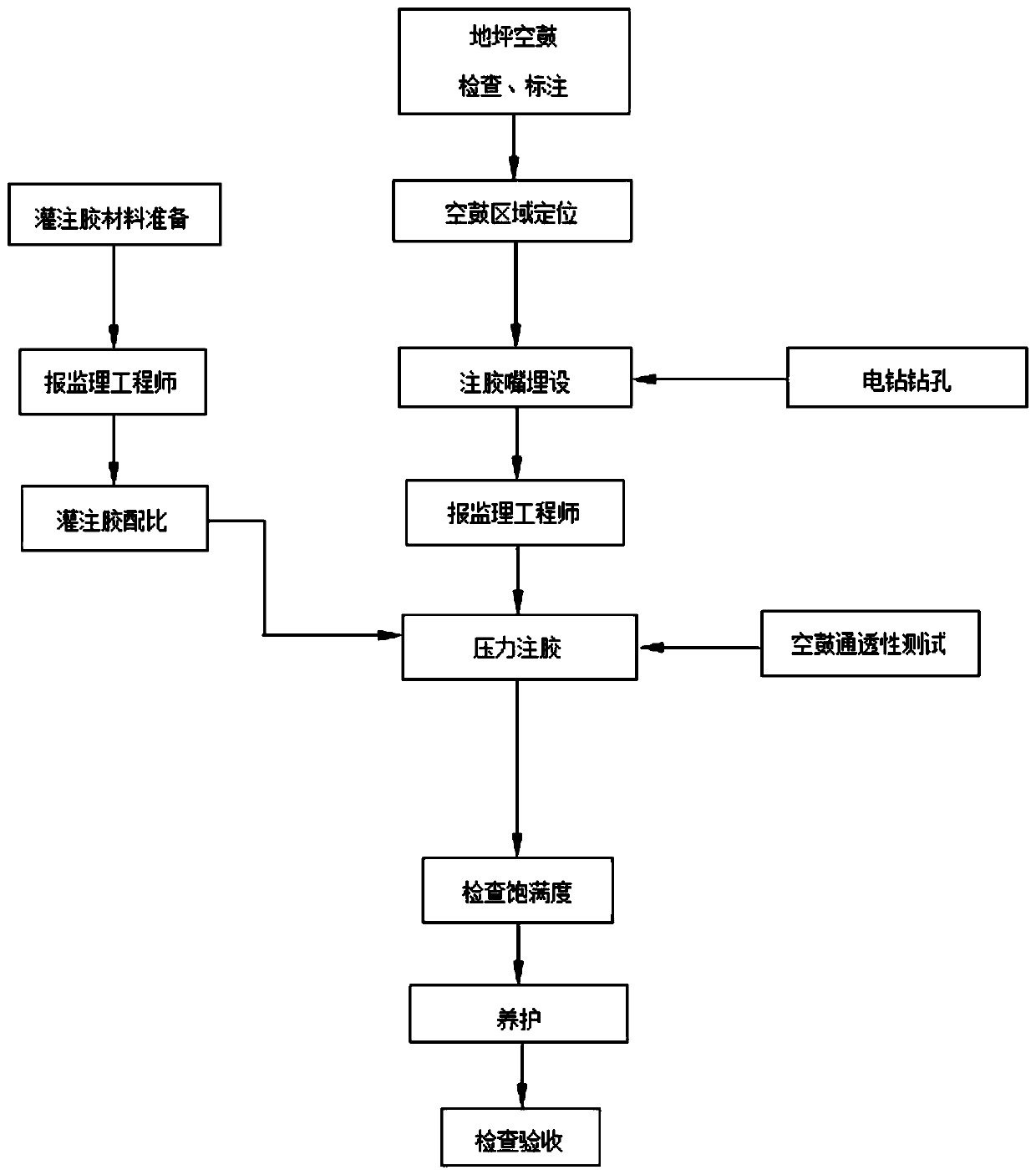

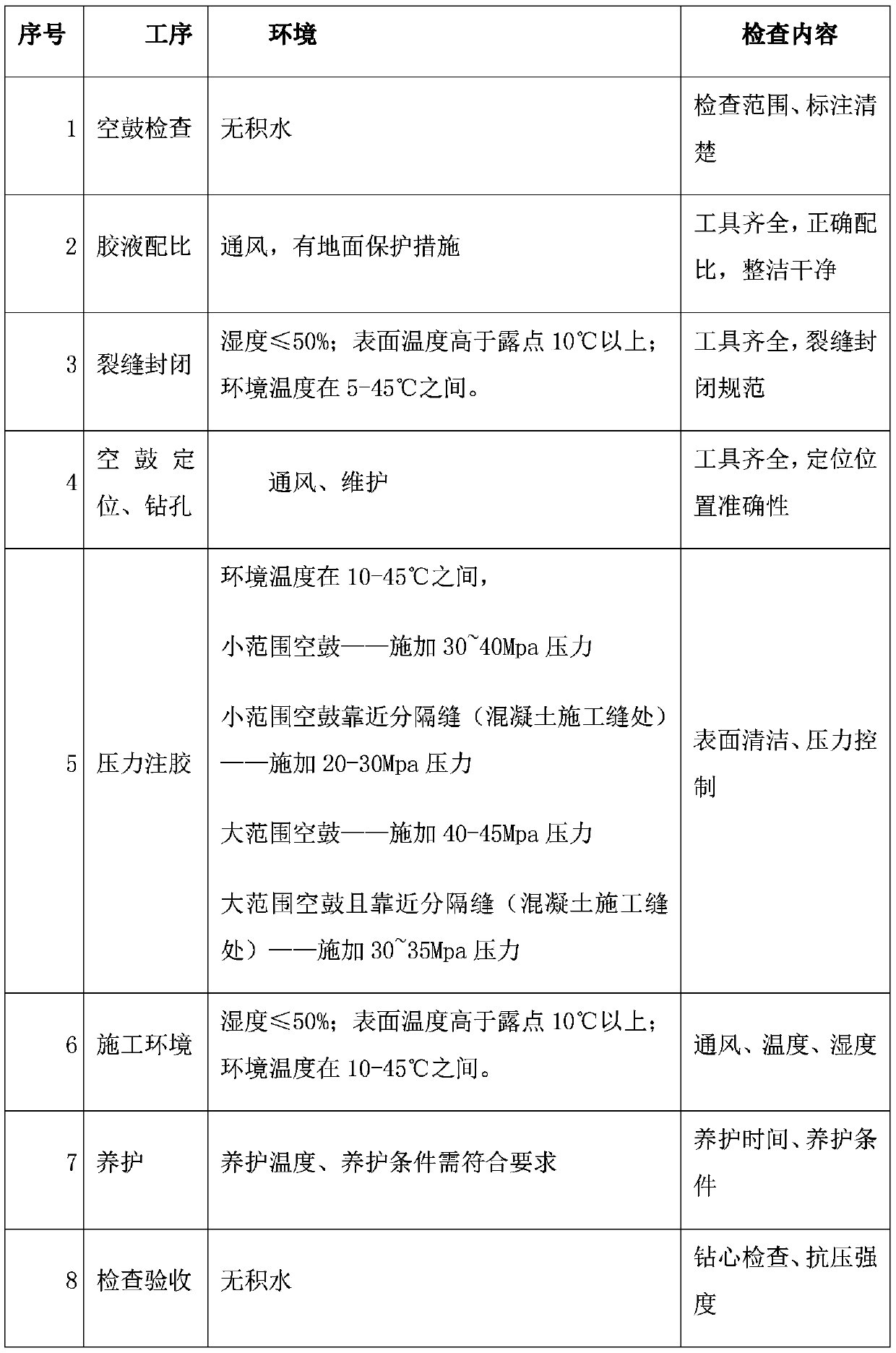

[0023] This embodiment provides a construction method for repairing hollow micropores on wear-resistant emery floors, including the following steps:

[0024] ⑴Before construction, hit the empty drum on the site floor with a small hammer, make a comprehensive and detailed statistics, and clearly mark the empty drum on the drawing;

[0025] ⑵Selection and positioning of the glue injection space, according to the area marked on the drawing, the construction personnel will design and locate the drilling position of each hollow drum on site, use an electric drill to drill the selected position of the hollow drum, and bury the glue injection at the drilled hole mouth;

[0026] (3) Before using the high-pressure pump to inject glue, first conduct a permeability test on the drilled hole to make the drilled hole have good permeability and lay the foundation for smooth grouting;

[0027] ⑷In order to ensure that the grout does not flow out when the grouting is pressurized, the cracks o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com