Preparation method of carbon-10 heavy aromatics low-naphthalene high-boiling-point aromatics solvents

A technology for high-boiling aromatics and heavy aromatics, applied in separation methods, chemical instruments and methods, hydrocarbon distillation, etc., can solve problems such as high naphthalene content, achieve high boiling point, good environmental performance, and stable chemical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

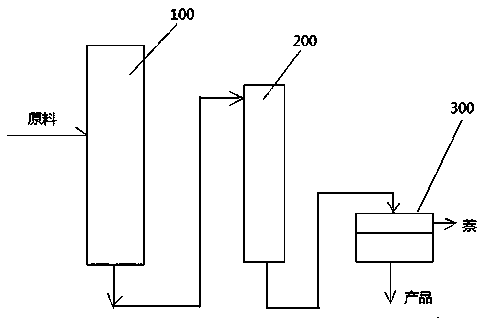

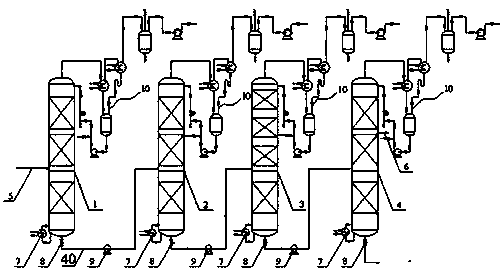

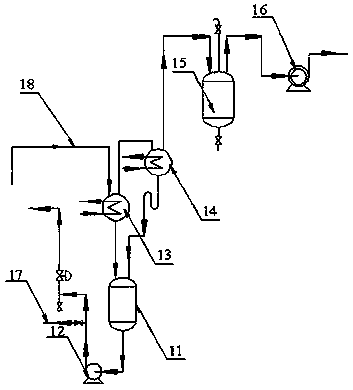

[0015] see figure 1 , figure 2 and image 3 , the preparation method of described carbon ten heavy aromatic hydrocarbon low naphthalene high boiling point aromatic hydrocarbon solvent, comprises the steps:

[0016] (1) Separating the carbon-deca-heavy aromatics from the raw material by using a multi-stage rectification device 100 through a rectification method, and collecting products with a distillation range of 260-290°C;

[0017] (2) Pass the product obtained in step (1) through the crystallization device 200 and the liquid-solid separation device 300 in sequence, and the obtained mother liquor is the above-mentioned C10-heavy aromatic hydrocarbon solvent with low naphthalene and high boiling point, which is low naphthalene S-200 Solvent oil, the crystal is naphthalene;

[0018] The crystallization temperature is -5~-26°C;

[0019] Preferably, the raw material C10-heavy aromatics is introduced into four stages of vacuum rectification units connected in series, and then...

Embodiment 1

[0060] Feed raw carbon ten heavy aromatics into Figure 1~Figure 4 In the device shown, the product with a distillation range of 260~290°C is collected from the fourth-stage rectification tower, and then passes through the crystallization device 200 and the liquid-solid separation device 300 in sequence, and the obtained mother liquor is the above-mentioned carbon ten heavy aromatic hydrocarbon low naphthalene High-boiling aromatic hydrocarbon solvent, that is, low-naphthalene S-200 solvent oil, the crystal is naphthalene;

[0061] Among them, the structural parameters of the crystallization device:

[0062] The inner cavity of the crystallizer is divided into five cooling sections 23;

[0063] Pre-cool the product of step (1) to -5°C;

[0064] From top to bottom, the temperature of the last cooling section 23 is -25°C;

[0065] The residence time of the product of step (1) in the crystallizer is 15 minutes, and the linear velocity in the crystallization tube 21 is 1 m / s;

...

Embodiment 2

[0074] Feed raw carbon ten heavy aromatics into Figure 1~Figure 4 In the device shown, the product with a distillation range of 260~290°C is collected from the fourth-stage rectification tower, and then passes through the crystallization device 200 and the liquid-solid separation device 300 in sequence, and the obtained mother liquor is the above-mentioned carbon ten heavy aromatic hydrocarbon low naphthalene High-boiling aromatic hydrocarbon solvent, that is, low-naphthalene S-200 solvent oil, the crystal is naphthalene;

[0075] Among them, the structural parameters of the crystallization device:

[0076] The inner cavity of the crystallizer is divided into 8 cooling sections 23;

[0077] Pre-cool the product of step (1) to -10°C;

[0078] The temperature of the last cooling section 23 is -25°C;

[0079] The residence time of the product of step (1) in the crystallizer is 30 minutes, and the linear velocity in the crystallization tube 21 is 3 m / s;

[0080] The raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com