Fracturing fluid system and application thereof in continuous mixing fracturing technique

A fracturing fluid and system technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high preparation cost and difficult process, reduce manual labor, solve high preparation cost, and improve liquid preparation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

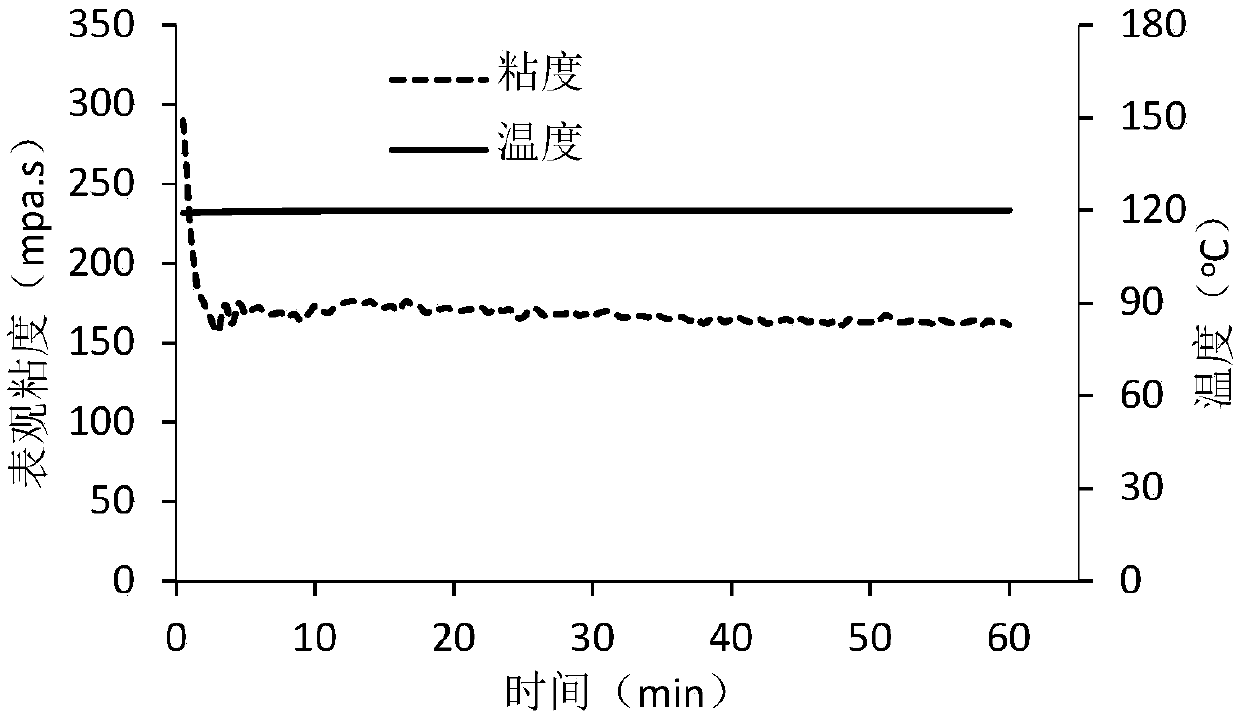

Image

Examples

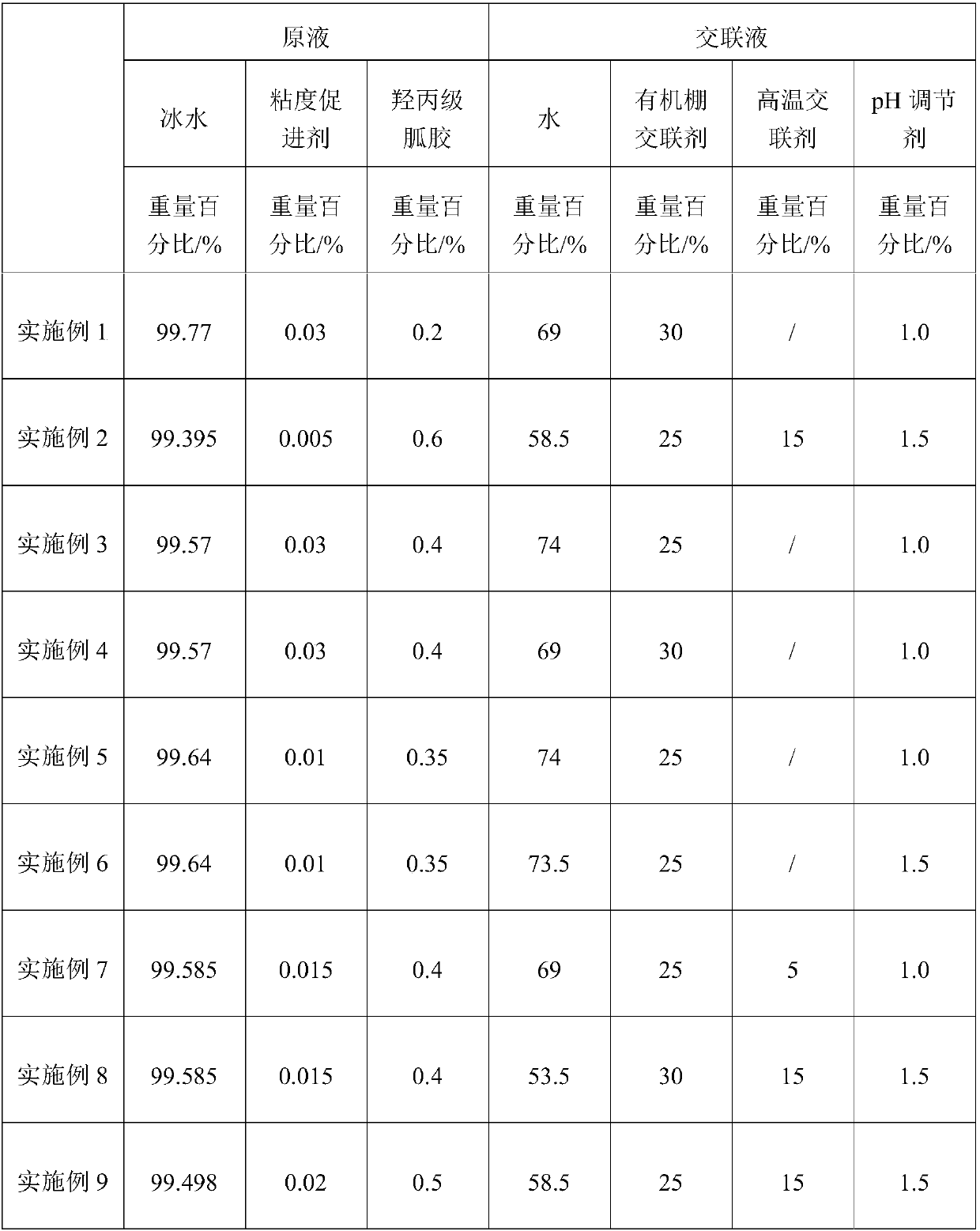

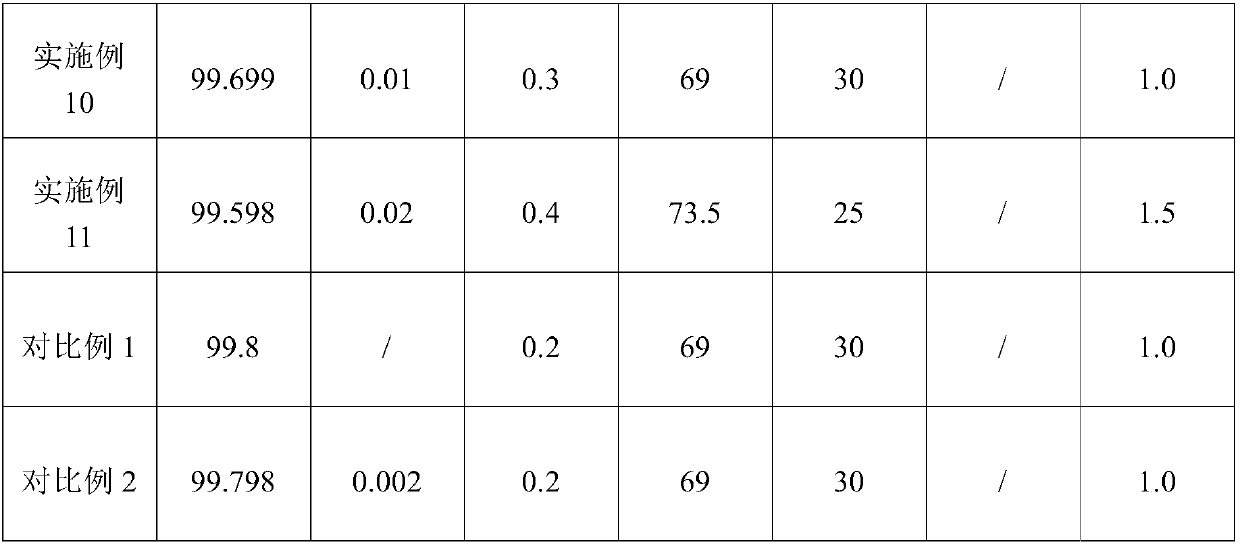

Embodiment 1

[0035] The fracturing fluid system provided in this embodiment includes the following preparation processes:

[0036] Add oxalic acid, a viscosity enhancer, to ice water at 3°C, stir and mix evenly, add hydroxypropyl guar gum (Kunshan first grade), stir quickly for 1 min and mix well, swell at rest to obtain the original solution;

[0037] Add organic shed crosslinking agent YGB (provided by the pilot plant of Engineering Technology Research Institute of Xinjiang Oilfield Company) and pH adjuster NaOH into the water, and mix well to obtain a crosslinking liquid;

[0038] Mix the above-mentioned stock solution and the above-mentioned cross-linking liquid at a volume ratio of 100:1, add the breaker sodium persulfate and stir evenly, the cross-linking time is 1.0min, to obtain the fracturing fluid system, the fracturing fluid system The mass percentage is 0.12%.

Embodiment 2

[0040] The fracturing fluid system provided in this embodiment includes the following preparation processes:

[0041] Add oxalic acid, a viscosity enhancer, to ice water at 3°C, stir and mix evenly, add hydroxyprom guar gum (Kunshan first grade), stir quickly for 1 min and mix well, swell at rest to obtain the original solution;

[0042] Add organic shed crosslinking agent YGB (provided by Xinjiang Oilfield Company Engineering Technology Research Institute pilot plant), organic zirconium high temperature crosslinking agent HT (provided by Xinjiang Oilfield Company Engineering Technology Institute pilot plant) and pH regulator NaOH into the water , Mix well to obtain cross-linking liquid;

[0043] Mix the above-mentioned stock solution and the above-mentioned cross-linking liquid in a volume ratio of 100:1, add the gel breaker capsule breaker and stir evenly, the cross-linking time is 1.5min, to obtain the fracturing fluid system, the gel breaker in the fracturing fluid system The ma...

Embodiment 3

[0045] The fracturing fluid system provided in this embodiment includes the following preparation processes:

[0046] Add oxalic acid, a viscosity enhancer, to ice water at 3°C, stir and mix evenly, add hydroxypropyl guar gum (Kunshan first grade), stir quickly for 1 min and mix well, swell at rest to obtain the original solution;

[0047] Add organic shed crosslinking agent YGB (provided by the pilot plant of Engineering Technology Research Institute of Xinjiang Oilfield Company) and pH adjuster NaOH into the water, and mix well to obtain a crosslinking liquid;

[0048] Mix the above-mentioned stock solution and the above-mentioned cross-linking liquid in a volume ratio of 100:1, add the breaker sodium persulfate and stir evenly, and the cross-linking time is 1.0min to obtain the fracturing fluid system. The mass percentage is 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com