A kind of food-grade cellulose gum and preparation method thereof

A cellulose glue, food-grade technology, applied in the field of food-grade cellulose glue and its preparation, can solve the problem of fast viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

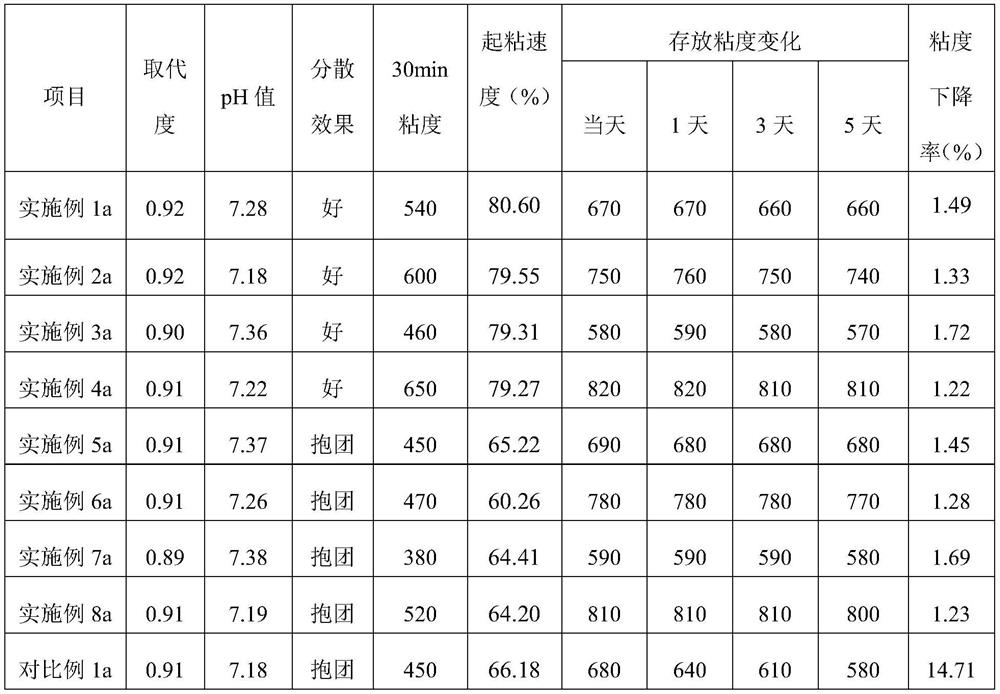

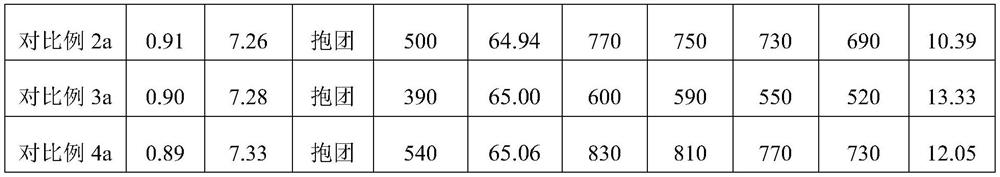

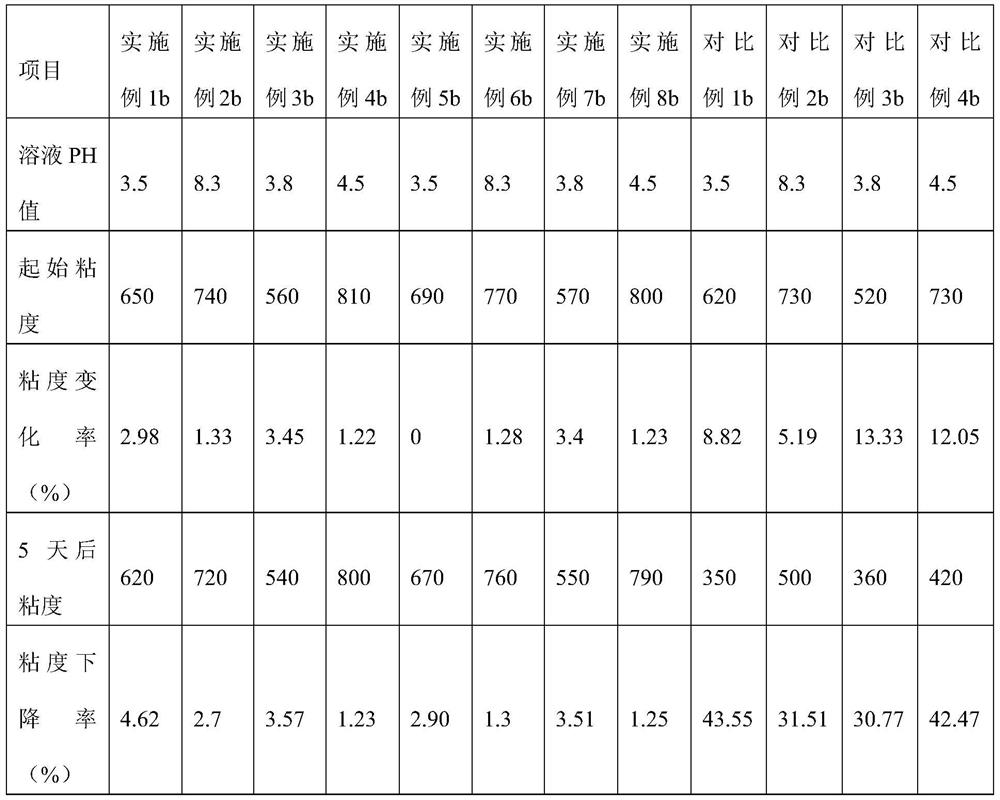

Examples

Embodiment 1

[0026] (1) Under stirring conditions, 1000g of the dissolving slurry with a degree of polymerization of 1920 is added to 940g of a mass concentration of 35% sodium hydroxide solution, and the temperature is controlled at 25-30°C for stirring and pretreatment for 80 minutes. The finished alkali cellulose is squeezed and filtered, and the treated alkali cellulose solid is left.

[0027] (2) the alkali cellulose that has been processed is 1708g, joins and puts 772g mass concentration and is that 52% sodium hydroxide aqueous solution and 2500g volume concentration are in the kneader of the mixed liquor of 92% alcohol aqueous solution, carry out stirring alkalization, temperature Control the temperature at 20-25°C, and control the alkalization time for 50 minutes.

[0028] (3) After the alkalization is finished, add 1000 g of chloroacetic acid alcohol solution with a mass concentration of 75%, and drop it in 15 minutes. The material is taken out.

[0029] (4) put the cooled mater...

Embodiment 2

[0033] (1) Under stirring conditions, 1000g of the dissolving slurry with a degree of polymerization of 2050 is added to 1095g of a mass concentration of 30% sodium hydroxide solution, and the temperature is controlled at 22-27°C for stirring and pretreatment for 50min. The finished alkali cellulose is squeezed and filtered, and the treated alkali cellulose solid is left.

[0034] (2) the alkali cellulose handled is 1750g, joins and puts 803g mass concentration and is that 50% sodium hydroxide aqueous solution and 2800g volume concentration are in the kneader of the mixed liquor of 94% alcohol aqueous solution, carry out stirring alkalization, temperature Control the temperature at 22-26°C, and control the alkalization time for 30 minutes.

[0035] (3) After the alkalization is finished, add 1000 g of chloroacetic acid alcohol solution with a mass concentration of 75%, and drop it in 30 minutes. The material is taken out.

[0036] (4) put the cooled material into the alcohol...

Embodiment 3

[0040] (1) Under stirring conditions, 1000g of the dissolving slurry with a degree of polymerization of 1810 is added to 1310g of a mass concentration of 25% sodium hydroxide solution, and the temperature is controlled at 15-20°C for agitation pretreatment for 120min, and the pretreatment The finished alkali cellulose is squeezed and filtered, and the treated alkali cellulose solid is left.

[0041] (2) the alkali cellulose that has been processed is 1800g, joins and puts 892g mass concentration and is that 45% sodium hydroxide aqueous solution and 3000g volume concentration are in the kneader of the mixed liquor of 93% alcohol aqueous solution, carry out stirring alkalization, temperature Control the temperature at 27-31°C, and control the alkalization time for 60 minutes.

[0042] (3) After the alkalization is finished, add 1000 g of chloroacetic acid alcohol solution with a mass concentration of 75%, and drop it in 20 minutes. The material is taken out.

[0043] (4) Put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com