Feve fluorocarbon metal powder coating for metal surface and preparation method thereof

A metal powder, metal surface technology, applied in the field of FEVE fluorocarbon metal powder coating and its preparation, can solve the problems of uneven distribution of charged properties, poor weather resistance of resin, multiple coating, etc., achieve significant metal effect, strengthen metal effect, the effect of solving the reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

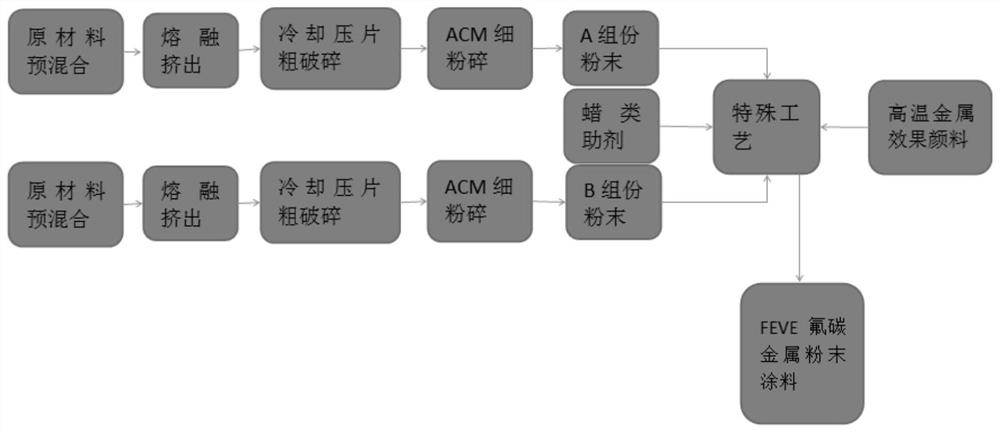

Method used

Image

Examples

Embodiment 1

[0040] A kind of FEVE fluorocarbon metal powder coating for metal surface, it is characterized in that, comprises A component, B component, according to weight ratio, the ratio of described A component, B component is respectively A:B=9:1 , A:B=7:3, A:B=5:5, and sample powder 1, sample powder 2 and sample powder 3 were prepared by adding wax additives and metal pigments on components A and B ;

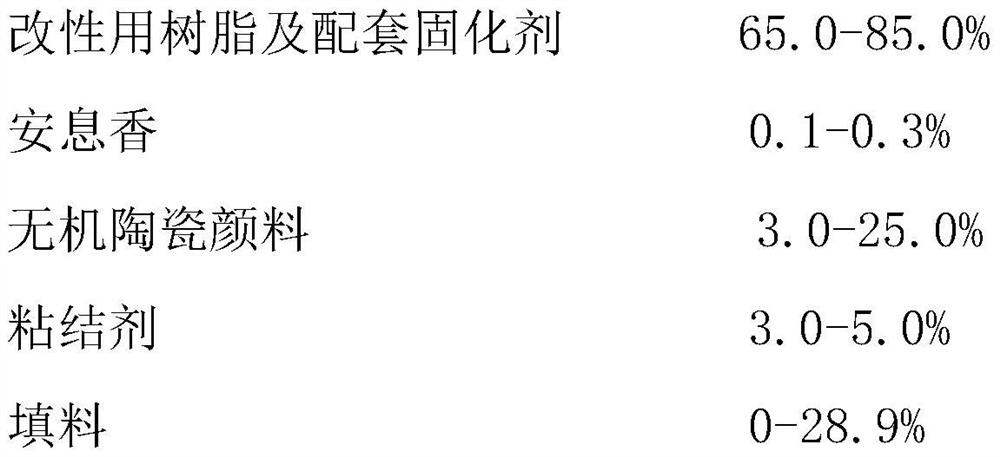

[0041] Described A component is made up of following raw material by weight percentage:

[0042]

[0043] The sum of the above percentages is 100%;

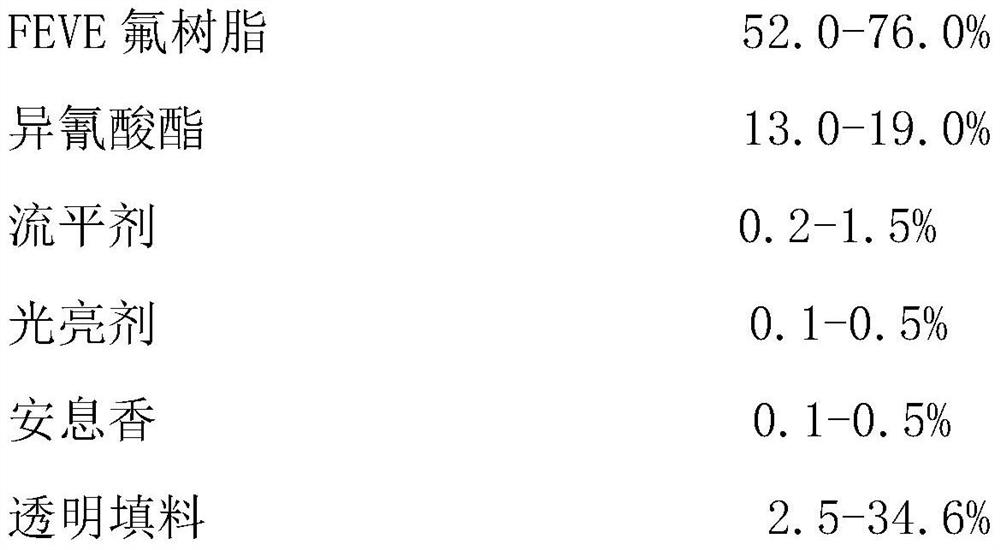

[0044] The B component is composed of the following raw materials by weight percentage:

[0045]

[0046] The sum of the above percentages is 100%;

[0047] The added amount of the wax additive is 2.0% of the total weight of the A component and the B component; the added amount of the metal pigment is 0.5% of the total weight of the A component and the B component.

[0048] (1) Weigh the raw materials of component A and componen...

Embodiment 2

[0054] Sample powder 4 was prepared by adding wax additives and aluminum metal pigments to the following components A and B according to the weight ratio A:B=5:5:

[0055] Described A component is made up of following raw material by weight percentage:

[0056]

[0057] The sum of the above percentages is 100%;

[0058] The B component is composed of the following raw materials by weight percentage:

[0059]

[0060] The sum of the above percentages is 100%;

[0061] The addition percentage of the wax additive is 2.0% of the total weight of the A component and the B component;

[0062] The metal pigment addition percentage of the aluminum is 0.5% of the total weight of the A component and the B component;

[0063] The preparation technology of described sample powder 4 comprises the steps:

[0064] (1) Weigh the raw materials of component A and component B respectively according to the formula percentage, and obtain powder A and powder B after the steps of melt extru...

Embodiment 3

[0074] Sample powder 5 and sample powder 6 were prepared by adding wax additives and aluminum metal pigments by adding the following components A and B according to the weight ratio A:B=5:5 through a special process and a dry mixing process:

[0075] Described A component is made up of following raw material by weight percentage:

[0076]

[0077] The sum of the above percentages is 100%;

[0078] The B component is composed of the following raw materials by weight percentage:

[0079]

[0080] The sum of the above percentages is 100%;

[0081] The addition percentage of the wax additive is 0.1% of the total weight of the A component and the B component;

[0082] The addition percentage of the metal pigment is 15.0% of the total weight of the A component and the B component;

[0083] (1) Weigh the raw materials of component A and component B according to the formula percentage respectively, and obtain powder A and powder B respectively after the steps of melt extrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com