Preparation method of special high-strength hot melt adhesive for bonding glass

A hot-melt adhesive, high-strength technology, used in adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problems of inconvenient operation, slow curing speed, etc., achieve good adhesion effect, slow drying speed, The effect of the quick stick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

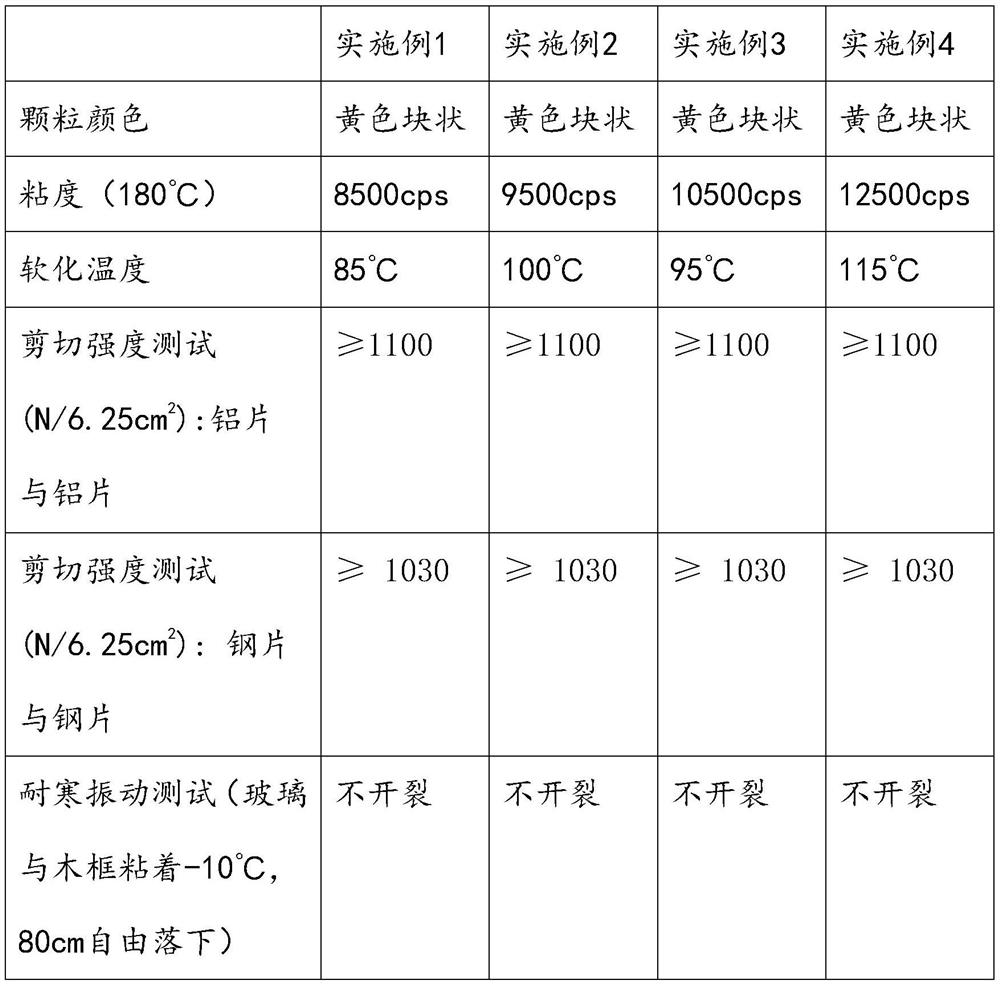

Examples

Embodiment 1

[0026] Prepare raw materials (percentage by weight) SIS, 30%; Mineral oil, 2%; Stabilizer, 3%; Terpene phenolic resin, 65%; Heating the reactor, when the oil gauge shows that the oil temperature reaches 180°C, the raw materials SIS, Mineral oil and stabilizer are slowly added to the reactor in turn, then cover the lid of the reactor, turn on the motor of the reactor to stir, control the motor speed between 10-15 rpm, and keep the oil temperature of the reactor at 195-205°C; stir for 45 Minutes later, after all the raw materials are melted, open the lid of the reactor and put in the terpene phenolic resin, then cover the lid of the reactor and lock it tightly, and continue to stir and melt; the motor speed is controlled at 15-50 rpm during feeding Time; confirm that all raw materials have been melted, turn on the vacuum machine switch to extract the air in the glue, control the vacuum time between 45-60 minutes, and control the motor speed between 8-50 rpm; heat the reaction ket...

Embodiment 2

[0028] Prepare raw materials (percentage by weight) SIS, 65%; Mineral oil, 10%; Stabilizer, 5%; Terpene phenolic resin, 20%; Heating the reactor, when the oil meter shows that the oil temperature reaches 180°C, the raw materials SIS, Mineral oil and stabilizer are slowly added to the reactor in turn, then cover the lid of the reactor, turn on the motor of the reactor to stir, control the motor speed between 10-15 rpm, and keep the oil temperature of the reactor at 195-205°C; stir for 45 Minutes later, after all the raw materials are melted, open the lid of the reactor and put in the terpene phenolic resin, then cover the lid of the reactor and lock it tightly, and continue to stir and melt; the motor speed is controlled at 15-50 rpm during feeding Time; confirm that all raw materials have been melted, turn on the vacuum machine switch to extract the air in the glue, control the vacuum time between 45-60 minutes, and control the motor speed between 8-50 rpm; heat the reaction ke...

Embodiment 3

[0030] Prepare raw materials (percentage by weight) SIS, 40%; Mineral oil, 10%; Stabilizer, 5%; Terpene phenolic resin, 45%; Heating the reactor, when the oil gauge shows that the oil temperature reaches 180°C, the raw materials SIS, Mineral oil and stabilizer are slowly added to the reactor in turn, then cover the lid of the reactor, turn on the motor of the reactor to stir, control the motor speed between 10-15 rpm, and keep the oil temperature of the reactor at 195-205°C; stir for 45 Minutes later, after all the raw materials are melted, open the lid of the reactor and put in the terpene phenolic resin, then cover the lid of the reactor and lock it tightly, and continue to stir and melt; the motor speed is controlled at 15-50 rpm during feeding Time; confirm that all raw materials have been melted, turn on the vacuum machine switch to extract the air in the glue, control the vacuum time between 45-60 minutes, and control the motor speed between 8-50 rpm; heat the reaction ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com