Method for preparing slurry from carbon black through dry treatment

A technology for preparing slurry and dry treatment is applied in the field of preparing carbon black slurry, which can solve the problems of poor carbon black dispersibility and unenvironmental protection of carbon black dyeing, and achieve the effect of long-term storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

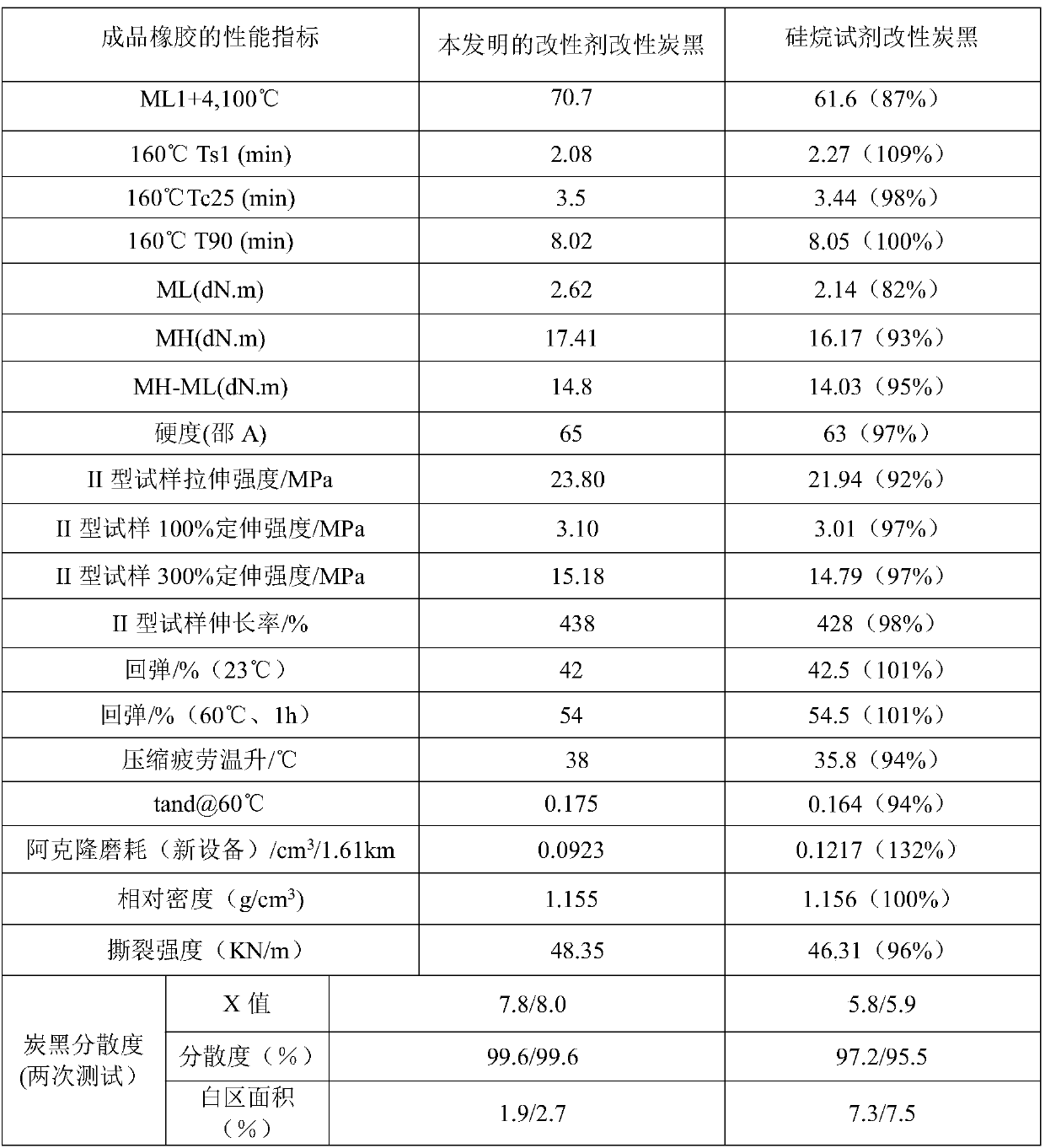

Image

Examples

Embodiment 1

[0015] After the carbon black is pulverized by a low-speed pulverizer and ground by a grinder, the surface grafting treatment is carried out with the boric acid ester at a mass ratio of 100:0.5, so that the carbon black changes from hydrophobicity to hydrophilicity; the grafting treatment process includes: Stir and mix in a branch tank, the temperature is 150°C, the pressure is 0.1MPa, the rotation speed is 1000r / min, and the time is 2h.

[0016] The treated carbon black is added with distilled water at a concentration of 30%, and mixed in a mixer, and the mixed solution containing carbon black is emulsified in a high-speed shear machine, and the speed of the high-speed shear machine is above 5000r / min.

Embodiment 2

[0018] After the carbon black is pulverized with a low-speed pulverizer and ground by a grinder, the surface grafting treatment is carried out with the methyl oleic acid ester in a mass ratio of 100:10, so that the carbon black changes from hydrophobicity to hydrophilicity; the grafting treatment process includes : stirring and mixing in a grafting tank, the temperature is 250° C., the pressure is 0.5 MPa, the rotation speed is 300 r / min, and the time is 6 hours.

[0019] The treated carbon black is added with distilled water at a concentration of 5%, and mixed in a mixer, and the mixed solution containing carbon black is emulsified in a high-speed shear machine, and the speed of the high-speed shear machine is above 5000r / min.

Embodiment 3

[0021] After the carbon black is pulverized by a low-speed pulverizer and ground by a grinder, the surface is grafted with a mixture of titanate and aluminate in a mass ratio of 100:5, so that the carbon black changes from hydrophobicity to hydrophilicity; grafting The treatment process includes: stirring and mixing in the grafting tank, the temperature is 200° C., the pressure is 0.3 MPa, the rotation speed is 600 r / min, and the time is 4 hours.

[0022] The treated carbon black is added with distilled water at a concentration of 17%, and mixed in a mixer, and the mixed solution containing carbon black is emulsified in a high-speed shear, and the speed of the high-speed shear is above 5000r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com