Differential circulating fluidized bed catalytic pyrolysis gasification apparatus and differential circulating fluidized bed catalytic pyrolysis gasification method

A circulating fluidized bed, pyrolysis gasification technology, applied in the field of coal gasification, can solve the problems of poor operation stability, low carbon conversion rate and gasification intensity, low methane yield, etc., and achieves reduced load and high gasification intensity. , the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

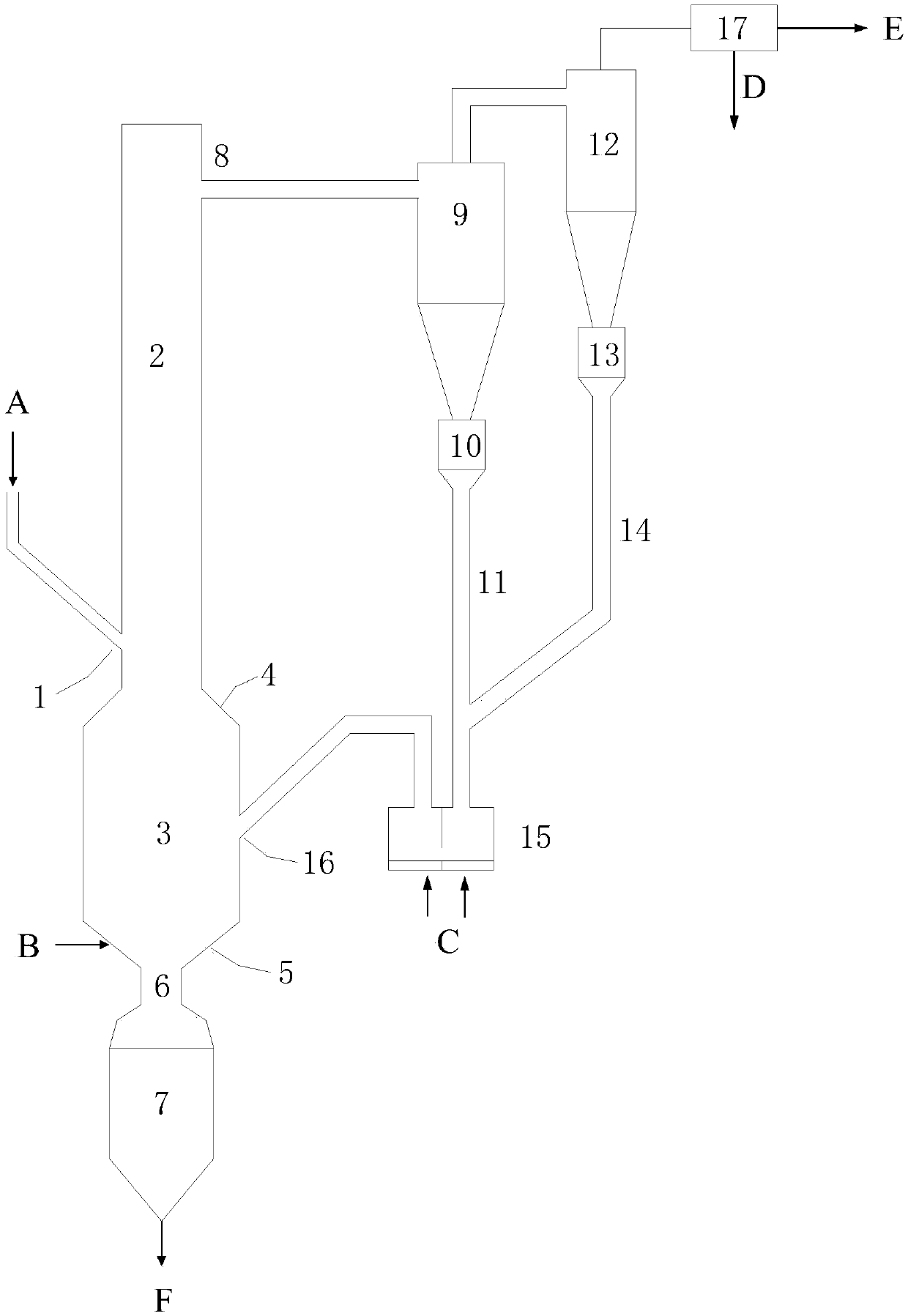

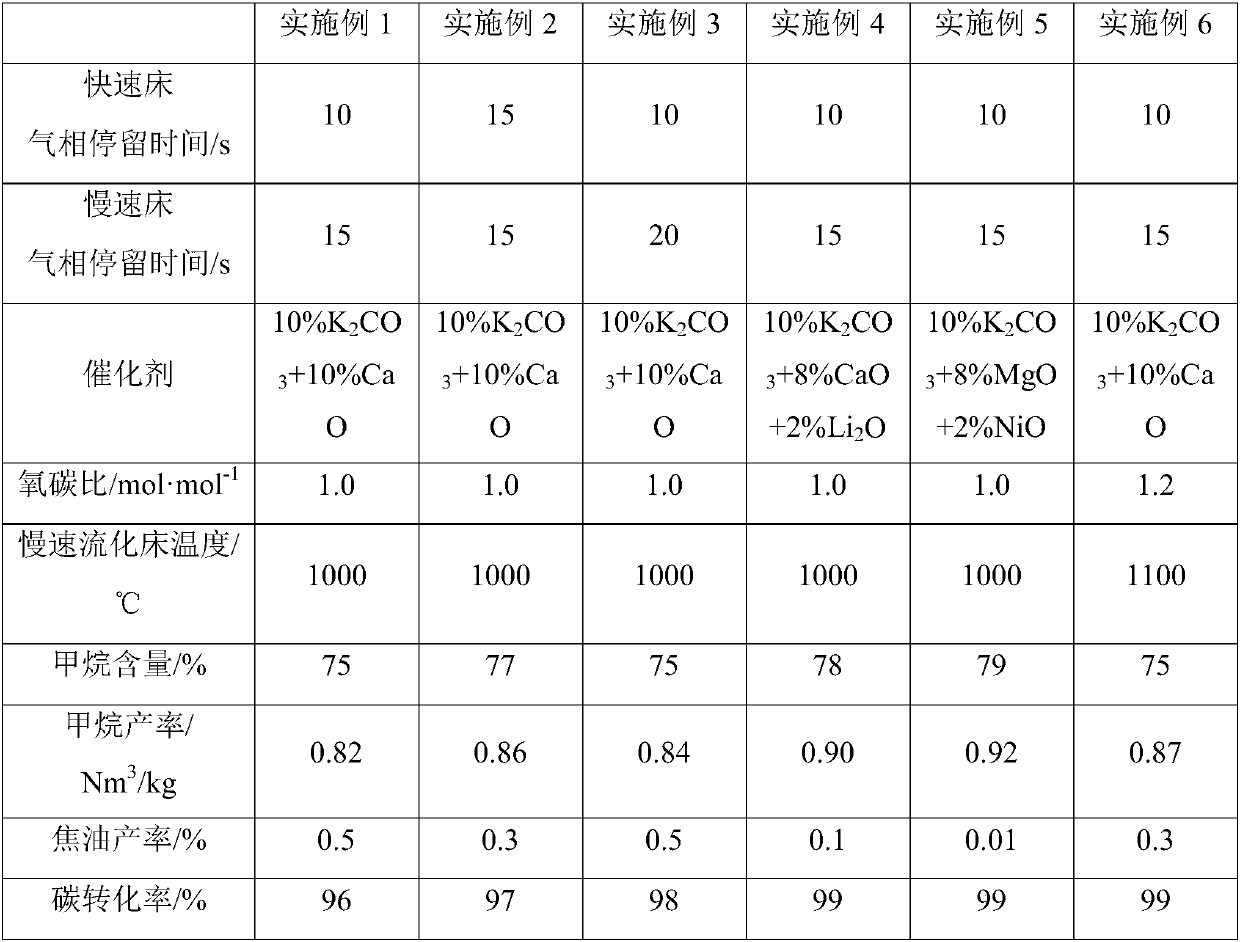

[0046] A differential circulating fluidized bed catalytic pyrolysis gasification reaction device, the inner diameter of the fast fluidized bed is 0.2m, the linear velocity is 2m / s, the gas phase residence time is 10s, the inner diameter of the slow fluidized bed is 0.5m, and the linear velocity is 0.2m / s , the gas phase residence time is 15s, the raw material inlet is located at 1 / 8 of the height of the fast fluidized bed, the angle between the constriction and the horizontal axis is 45°, the angle between the inclined surface of the gas distributor and the horizontal axis is 30°, the conical surface of the gas distributor There are 10 circles of pores on the top, the opening rate is 1.5%, and the inner diameter of the lower slag opening is 0.2m.

[0047] In the experiment, Inner Mongolia lignite and 10% K 2 CO 3 +10%CaO catalyst mixed, fed into the fast fluidized bed from the raw material inlet, mixed and contacted with the high-temperature synthesis gas from the necking, to...

Embodiment 2

[0049] A differential circulating fluidized bed catalytic pyrolysis gasification reaction device, the inner diameter of the fast fluidized bed is 0.2m, the linear velocity is 2m / s, the gas phase residence time is 15s, the inner diameter of the slow fluidized bed is 0.5m, and the linear velocity is 0.2m / s , the gas phase residence time is 15s, the raw material inlet is located at 1 / 8 of the height of the fast fluidized bed, the angle between the constriction and the horizontal axis is 45°, the angle between the inclined surface of the gas distributor and the horizontal axis is 30°, the conical surface of the gas distributor There are 10 circles of pores on the top, the opening rate is 1.5%, and the inner diameter of the lower slag opening is 0.2m.

[0050] In the experiment, Inner Mongolia lignite and 10% K 2 CO 3 +10%CaO catalyst mixed, fed into the fast fluidized bed from the raw material inlet, mixed and contacted with the high-temperature synthesis gas from the necking, to...

Embodiment 3

[0052] A differential circulating fluidized bed catalytic pyrolysis gasification reaction device, the inner diameter of the fast fluidized bed is 0.2m, the linear velocity is 2m / s, the gas phase residence time is 10s, the inner diameter of the slow fluidized bed is 0.5m, and the linear velocity is 0.2m / s , the gas phase residence time is 20s, the raw material inlet is located at 1 / 8 of the height of the fast fluidized bed, the angle between the constriction and the horizontal axis is 45°, the angle between the inclined surface of the gas distributor and the horizontal axis is 30°, the conical surface of the gas distributor There are 10 circles of pores on the top, the opening rate is 1.5%, and the inner diameter of the lower slag opening is 0.2m.

[0053] In the experiment, Inner Mongolia lignite and 10% K 2 CO 3 +10%CaO catalyst mixed, fed into the fast fluidized bed from the raw material inlet, mixed with the high-temperature syngas from the shrinkage port, to carry out pyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com